March's Advanced Organic Chemistry: Reactions, Mechanisms, and Structure, 7th Edition (2013)

Part II. Introduction

Chapter 12. Aliphatic, Alkenyl, and Alkynyl Substitution, Electrophilic and Organometallic

12.C. Reactions

The reactions in this chapter are arranged in order of leaving group: hydrogen, metals, halogen, and carbon. Electrophilic substitutions at a nitrogen atom are treated last.

12.C.i. Hydrogen as Leaving Group

A. Hydrogen as the Electrophile

12-1 Hydrogen Exchange

Deuterio-de-hydrogenation or Deuteriation

![]()

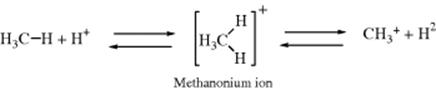

Hydrogen exchange can be accomplished by treatment with acids or bases. As with Reaction 11-1, the exchange reaction is mostly used to study mechanistic questions (e.g., relative acidities), but it can be used synthetically to prepare deuterated or tritiated molecules. When ordinary strong acids (e.g., H2SO4) are used, only fairly acidic protons on carbon can exchange (e.g., acetylenic and allylic). However, primary, secondary, and tertiary hydrogen atoms of alkanes can be exchanged by treatment with superacids (Sec. 5.A.ii).48 The order of hydrogen reactivity is tertiary > secondary > primary. Where C–C bonds are present, they may be cleaved also (Reaction 12-47). The mechanism of the exchange (illustrated for methane) has been formulated as involving attack of H+ on the C–H bond to give the pentavalent methanonium ion, which loses

H2 to give a tervalent carbocation.49 The methanonium ion (CH5+) has a three-center, two-electron bond.50 It is not known whether the methanonium ion is a transition state or a true intermediate, but an ion (CH5+) has been detected in the mass spectrum.51 The IR spectrum of the ethanonium ion (C2H7+) has been measured in the gas phase.52 Note that the two electrons in the three-center, two-electron bond can move in three directions, in accord with the threefold symmetry of such a structure. The electrons can move to unite the two hydrogen atoms, leaving the CH3+ free (the forward reaction), or they can unite the CH3 with either of the two hydrogen atoms, leaving the other hydrogen as a free H+ ion (the reverse reaction). Actually, the methyl cation is not stable under these conditions. It can go back to CH4 by the route shown (leading to H+ exchange), or it can react with additional CH4 molecules (Reaction 12-20) to eventually yield the tert-butyl cation, which is stable in these superacid solutions. Hydride ion can also be removed from alkanes (producing tervalent carbocations) by treatment with pure SbF5 in the absence of any source of H+.53 Complete or almost complete perdeuteriation of cyclic alkenes has been achieved by treatment with dilute DCl/D2O in sealed Pyrex tubes at 165–280 °C.54

Exchange with bases involves an SE1 mechanism.

![]()

Of course, such exchange is most successful for relatively acidic protons (e.g., those α to a carbonyl group), but even weakly acidic protons can exchange with bases if the bases are strong enough (see Sec. 5.B.i).

Alkanes and cycloalkanes, of both low and high molecular weight, can be fully perdeuterated treatment with D2 gas and a catalyst (e.g., Rh, Pt, or Pd).55

OS VI, 432.

12-2 Migration of Double Bonds

3/Hydro-de-hydrogenation

![]()

The double bonds of many unsaturated compounds may be isomerized56 upon treatment with strong bases.57 In many cases, equilibrium mixtures are obtained and the thermodynamically most stable isomer predominates.58 If the new double bond can be in conjugation with one already present or with an aromatic ring, the conjugated compound is favored.59 If the choice is between an exocyclic and an endocyclic double bond (particularly with six-membered rings), endocyclic is usually preferred. In the absence of such considerations, Zaitsev's rule (Sec. 17.B) applies and the double bond goes to the carbon with the fewest hydrogen atoms. All these considerations lead to predictions that terminal alkenes can be isomerized to internal ones, nonconjugated alkenes to conjugated, exo six-membered ring alkenes to endo, and so on, and not the other way around.

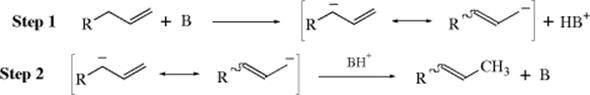

The term prototropic rearrangement is sometimes used as an example of electrophilic substitution with accompanying allylic rearrangement. The mechanism involves abstraction by a base to give a resonance-stabilized carbanion, and reaction with a proton is at the position that will give the more stable alkene:60

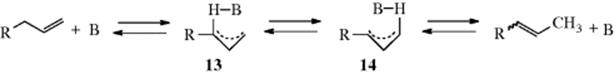

This mechanism is exactly analogous to the allylic-rearrangement mechanism for nucleophilic substitution (Sec. 10.D). Ultraviolet spectra of allylbenzene and 1-propenylbenzene in solutions containing NH2+ are identical, showing that the same carbanion is present in both cases, as required by this mechanism.61 The acid BH+ protonates the position that will give the more stable product, although the ratio of the two possible products can vary with the identity of BH+.62 It has been shown that base-catalyzed double-bond shifts are partially intramolecular, at least in some cases.63 The intramolecular nature has been ascribed to a conducted tour mechanism (Sec. 12.A.iii) in which the base leads the proton from one carbanionic site to the other (13 → 14).64

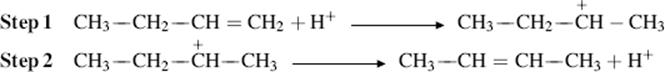

Double-bond rearrangements can also take place on treatment with acids. Both proton and Lewis65 acids can be used. The mechanism in the case of proton acids is the reverse of the previous one; first a proton is gained, giving a carbocation and then another is lost:

As in the case of the base-catalyzed reaction, the thermodynamically most stable alkene is the one predominantly formed. However, the acid-catalyzed reaction is much less synthetically useful because carbocations give rise to many side products. If the substrate has several possible locations for a double bond, mixtures of all possible isomers are usually obtained. Isomerization of 1-decene, for example, gives a mixture that contains not only 1-decene and cis-and trans-2-decene, but also the cis and trans isomers of 3-, 4-, and 5-decene as well as branched alkenes resulting from rearrangement of carbocations. It is true that the most stable alkenes predominate, but many of them have stabilities that are close together.

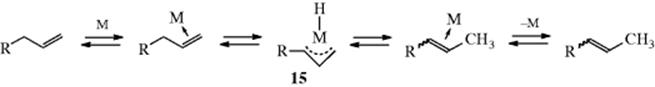

Double-bond isomerization can take place in other ways. Nucleophilic allylic rearrangements were discussed in Chapter 10 (Sec. 10.E). Electrocyclic and sigmatropic rearrangements are treated at Reactions 18-27 to 18-35. Double-bond migrations have also been accomplished photochemically,66 and by means of metallic ion (most often complex ions containing Pt, Rh, or Ru) or metal carbonyl catalysts.67 With metal compounds there are at least two possible mechanisms. One of these, which requires external hydrogen, is called the metal hydride addition–elimination mechanism:

![]()

The other mechanism, called the π-allyl complex mechanism, does not require external hydrogen and proceeds by hydrogen abstraction to form the η3-π-allyl complex 15 (see Sec. 3.C.i, category 1 and Reaction 10-60). Another difference between the two mechanisms is that the former involves 1,2- and the latter 1,3-shifts. The isomerization of 1-butene Rh catalyzed reaction is an example that takes place by the metal hydride mechanism,68 while an example of the π-allyl complex mechanism is found in the Fe3(CO)12 catalyzed isomerization of 3-ethyl-1-pentene.69 A Pd catalyst was used to convert alkynones (RCOC![]() CCH2CH2R′) to 2,4-alkadien-1-ones (RCOCH=CHCH=CHCHR′).70 The reaction of an en-yne with HSiCl3 and a Pd catalyst generated an allene with moderate enantioselectivity (see Sec. 4.C, category 5 for chiral allenes).71

CCH2CH2R′) to 2,4-alkadien-1-ones (RCOCH=CHCH=CHCHR′).70 The reaction of an en-yne with HSiCl3 and a Pd catalyst generated an allene with moderate enantioselectivity (see Sec. 4.C, category 5 for chiral allenes).71

The metal-catalysis method has been used for the preparation of simple enols, by isomerization of allylic alcohols, for example.72 Some enols are stable enough for isolation (see Sec. 4.Q.iv), but slowly tautomerize to the aldehyde or ketone, with half-lives ranging from 40 to 50 min to several days.72

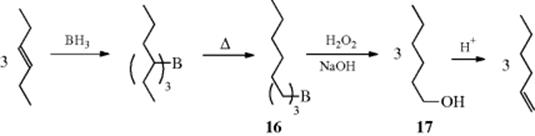

No matter which of the electrophilic methods of double-bond shifting is employed, the thermodynamically most stable alkene is usually formed in the largest amount, although a few anomalies are known. An indirect method of double-bond isomerization is known, leading to migration in the other direction. This involves conversion of the alkene to a borane (Reaction 15-16), rearrangement of the borane (Reaction 18-11), oxidation and hydrolysis of the newly formed borane to the alcohol (17) (see Reaction 12-31), and dehydration of the alcohol (Reaction 17-1) to the alkene. The reaction is driven by the fact that with heating the addition of borane is reversible, and the equilibrium favors formation of the less sterically hindered borane, 16 in this case.

Since the migration reaction is always toward the end of a chain, terminal alkenes can be produced from internal ones, so the migration is often opposite to that with the other methods. Alternatively, the rearranged borane can be converted directly to the alkene by heating with an alkene of molecular weight higher than that of the product (Reaction 17-15). Photochemical isomerization can also lead to the thermodynamically less stable isomer.73

See Reaction 15-1 for related reactions in which double bonds migrate or isomerize.

![]()

Triple bonds can also migrate in the presence of bases,74 but through an allene intermediate:75 In general, strong bases (e.g., NaNH2) convert internal alkynes to terminal alkynes (a particularly good base for this purpose is potassium 3-aminopropylamide, NH2CH2CH2CH2NHK76), because the equilibrium is shifted by formation of the acetylide ion. With weaker bases (e.g., NaOH), which are not strong enough to remove the acetylenic proton, the internal alkynes are favored because of their greater thermodynamic stability. In some cases, the reaction can be stopped at the allene stage.77 The reaction then becomes a method for the preparation of allenes.78 The reaction of propargylic alcohols with tosylhydrazine (PPh3) and DEAD also generates allenes.79 In a related reaction, base induced isomerization of propargylic alcohols leads to conjugated ketones in some cases.80 Acid-catalyzed migration of triple bonds (with allene intermediates) can be accomplished if very strong acids (e.g., HF–PF5) are used.81 If the mechanism is the same as that for double bonds, vinyl cations are intermediates.

OS II, 140; III, 207; IV, 189, 192, 195, 234, 398, 683; VI, 68, 87, 815, 925; VII, 249; VIII, 146, 196, 251, 396, 553; X, 156, 165; 81, 147

12-3 Keto–Enol Tautomerization

3/ O-Hydro-de-hydrogenation

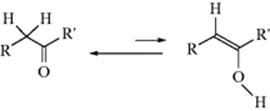

The tautomeric equilibrium between enols and ketones or aldehydes (keto–enol tautomerism) is a form of prototropy,82 but is not normally a preparative reaction. For some ketones, however, both forms can be prepared (see Sec. 2.N.i, category 3 for a discussion of this and other types of tautomerism). Keto–enol tautomerism occurs in systems containing one or more carbonyl groups linked to sp3 carbons bearing one or more hydrogen atoms. The keto is generally more stable than the enol tautomer for neutral systems, and for most ketones and aldehydes only the keto form is detectable under ordinary conditions. The availability of additional intramolecular stabilization through hydrogen bonding or complete electron delocalization (as in phenol), may cause the enol tautomer to be favored.

Keto–enol tautomerism is usally a slow process, but it can be catalyzed by a trace of acid or base.83 In this equilibrium, the heteroatom is the basic site and the proton is the acidic site. For tautomerism in general (see Sec. 2.N.i),84the presence of an acid or a base is not necessary to initiate the isomerization since each tautomeric substance possesses amphiprotic properties.84 Polar protic solvents (e.g., water or alcohol) may participate in the proton transfer by forming a cyclic or a linear complex with the tautomers.85 Whether the complex formed is cyclic or linear depends on the conformation and configuration of the tautomers. In a strongly polar aprotic solvent and in the presence of an acid or a base, the tautomeric molecule may lose or gain a proton and form the corresponding mesomeric anion or cation, which, in turn, may gain or lose a proton, respectively, and yield a new tautomeric form.86 The structural features of the carbonyl compound influences the equilibrium.87 Differing conjugative stabilization by CH-π orbital overlap does not directly influence stereoselectivity, and steric effects are generally not large enough to cause the several kilocalorie per mole (kcal mol−1) energy difference seen between transition structures unless there is exceptional crowding.88 Note that sterically stabilized enols are known,89 including arylacetaldehydes.90 Torsional strain involving vicinal bonds does contribute significantly to stereoselectivity in enolate formation.88

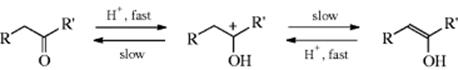

The acid base catalyzed mechanisms are identical to those in Reaction 12-2.91

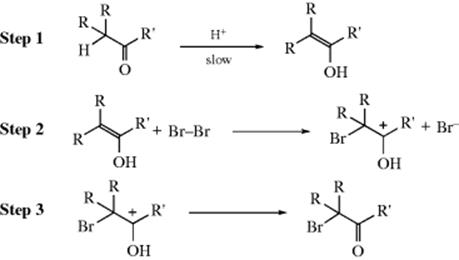

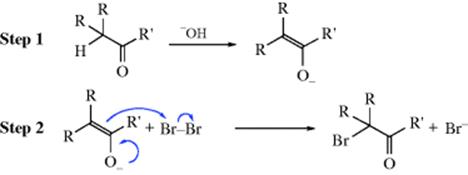

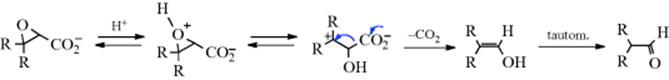

Acid catalyzed

Base catalyzed92

For each catalyst, the mechanism for one direction is the exact reverse of the other, by the principle of microscopic reversibility.93 As expected from mechanisms in which the C–H bond is broken in the rate-determining step, substrates of the type RCD2COR show deuterium isotope effects (of ~5) in both the basic-94 and the acid95-catalyzed processes. The keto–enol/enolate anion equilibrium has been studied in terms of the influence of β-oxygen96 or β-nitrogen97 substituents. The stereochemistry of enol protonation can be controlled by varying the proximal group and by changing the acidity of the medium.98

The base induced reaction generates an enolate anion rather than an enol, and the formation of and reactions of enolate anions are discussed further in Reactions 10-60, 10-67, 16-24, and 16-34. Note that ring strain plays no significant role on the rate of base-catalyzed enolization.99 In certain cases (e.g., benzofuranones), base-induced enolate anion formation may give a transition state in which aromaticity can play a role. One study showed that aromatic stabilization of the transition state is ahead of proton transfer, and aromaticity appears to lower the intrinsic barrier to this reaction.100 Enolizable hydrogen atoms can be replaced by deuterium (and ![]() by

by ![]() ) by passage of a sample through a deuterated (or

) by passage of a sample through a deuterated (or ![]() containing) gas-chromatography column.101

containing) gas-chromatography column.101

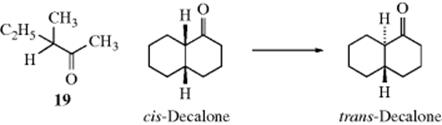

Although the conversion of an aldehyde or a ketone to its enol tautomer is not generally a preparative procedure, the reactions do have their preparative aspects. When enol ethers or esters are hydrolyzed, the initially formed enols immediately tautomerize to the aldehydes or ketones. In addition, the overall processes (forward plus reverse reactions) are often used for equilibration purposes. When an optically active compound in which the chirality is due to a stereogenic carbon α to a carbonyl group (as in 19) is treated with acid or base, racemization results.102 If there is another stereogenic center in the molecule, the less stable diastereomer can be converted to the more stable one in this manner. For example, cis-decalone can be equilibrated to the trans isomer. Isotopic exchange can similarly be accomplished at the α position of an aldehyde or ketone. In cyclic compounds, cis- to trans- isomerization can occur via the enol.103 The role of additives (e.g., ZnCl2) on the stereogenic enolization reactions using chiral cases has been discussed.104

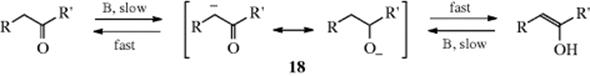

If a full equivalent of base per equivalent of ketone is used, the enolate ion (18) is formed and can be isolated105 (see, e.g., the alkylation reaction in Reaction 10-68).106 Enantioselective enolate anion protonation reactions have been studied.107 Enolate protonation is discussed in section Reaction 16-34. For the acid-catalyzed process, exchange or equilibration is accomplished only if the carbonyl compound is completely converted to the enol and then back, but in the base-catalyzed process exchange or equilibration can take place if only the first step (conversion to the enolate ion) takes place. The difference is usually academic. Aggregation behavior of stereoselective enolizations mediated by Mg and Ca bis(amides) have been studied.108

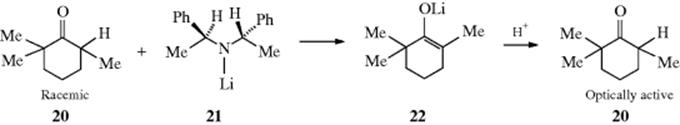

In the case of the ketone (20), a racemic mixture was converted to an optically active mixture (optical yield 46%) by treatment with the chiral base (21).109 This happened because 21 reacted with one enantiomer of 20 faster than with the other (an example of kinetic resolution). The enolate (22) must remain coordinated with the chiral amine, and it is the amine that reprotonate 22, not an added proton donor.

There are many enol–keto interconversions and acidification reactions of enolate ions to the keto forms listed in Organic Syntheses. No attempt is made to list them here.

B. Halogen Electrophiles

Halogenation of unactivated hydrocarbons is discussed in Reaction 14-1.

12-4 Halogenation of Aldehydes and Ketones

Halogenation or Halo-de-hydrogenation

Aldehydes and ketones can be halogenated in the α position with bromine, chlorine, or iodine,110 although the reaction is less successful with fluorine.111 Sulfuryl chloride,112 Me3SiCl–Me2SO,113 and NCS114 have been used as reagents for chlorination. α-Chloroaldehydes are formed with Cl2 and a catalytic amount of tetraethylammonium chloride.115 Bromination methods include NBS (see Reaction 14-3),116 Me3SiBr–DMSO,117 tetrabutylammonium tribromide,118 in situ generated ZnBr2 in water,119 and bromine•dioxane on silica with microwave irradiation.120 α-Chlorination121 and also bromination122 have been reported in ionic liquids. Enantioselective chlorination123 and bromination124 methods are known, including methods that use enolate anions as intermediates.125 Organocatalyzed asymmetric α-halogenation methods are known that can be applied to incorporation of virtually any halogen.126 β-Keto esters and 1,3-diketones are α-brominated using bromodimethylsulfonium bromide.127 1,3-Diketones, β-ketoesters, and malonates are chlorinated using sodium hypochlorite or brominated using sodium hypobromite.128

Iodination has been accomplished by the direct reaction of ketones with molecular iodine,129 with I2-cerium(IV) ammonium nitrate,130 NCS/NaI,131 ICl/NaI/FeCl3,132 and with iodine using 1-chloromethyl-4-fluoro-1,4-diazoniabicyclo[2.2.2]octane bis(tetrafluoroborate) in methanol.133 Methyl ketones react with NIS and tosic acid with microwave irradiation without solvent to give the α-iodoketone.134 An asymmetric iodination of aldehydes used NIS, with a catalytic amount of benzoic acid and a chiral biaryl amine.135

Although less prevalent than those noted above, several methods have been reported for the preparation of α-fluoro aldehydes and ketones,136 including enantioselective fluorination protocols.137 Organocatalytic α-fluorination is known for aldehydes and ketones.138 Selectfluor, [F–TEDA–BF4. 1-Fluoro-4-hydroxy-1,4-diazoniabicyclo[2.2.2]octane bis(tetrafluoroborate)] has been used for the monofluorination of ketones,139 as has a mixture of KI–KIO3–H2SO4.140 Active compounds (e.g., β-keto esters and β-diketones) have been fluorinated with an N-fluoro-N-alkylsulfonamide141 (this can result in enantioselective fluorination, if an optically active N-fluorosulfonamide is used142), with F2/N2–HCO2H,143 and with NF3O/Bu4NOH.144 Acetyl hypofluorite fluorinates simple ketones in the form of their lithium enolate anions.145 Aldehydes have been α-fluorinated using N-fluorobenzenesulfonimide as an electrophilic source of fluorine and an imidazolidinone as an organocatalyst.146 The enantioselective α-fluorination of oxindoles has been reported using N-fluorobenzenesulfonimide, a Pd catalyst, and a chiral ligand,147 and also with an organocatalyst.148

For unsymmetrical ketones, the preferred position of halogenation is usually the more substituted: a CH group, then a CH2 group, and then CH3149; however, mixtures are frequent. With aldehydes the aldehydic hydrogen is sometimes replaced, but only when there is no α-hydrogen and the reaction is generally not very useful (see Reaction 14-4). It is also possible to prepare di- and polyhalides. When basic catalysts are used, one α position of a ketone is completely halogenated before the other is attacked, and the reaction cannot be stopped until all the hydrogen atoms of the first carbon have been replaced (see below). If one of the groups is methyl, the haloform reaction (12-44) takes place. With acid catalysts, it is usually possible to stop the reaction after only one halogen has been incorporated, although a second halogen can be introduced by the use of excess reagent. In chlorination, the second halogen generally appears on the same side as the first,150 while in bromination the α,α′-dibromo product is found.151 Actually, with both halogens it is the α,α-dihalo ketone that is formed first, but in the case of bromination this compound isomerizes under the reaction conditions to the α,α′-isomer.150 α,α′-Dichloro ketones are formed by reaction of a methyl ketone with an excess of CuCl2 and LiCl in DMF152 or with HCl and H2O2 in methanol.153 Aryl methyl ketones can be dibrominated in high yields with benzyltrimethylammonium tribromide.154 Active methylene compounds are chlorinated with NCS and Mg(ClO4)2.155 Similar chlorination in the presence of a chiral copper catalyst led to α-chlorination with modest enantioselectivity.156

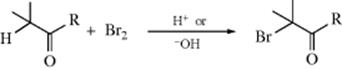

It is not the aldehyde or ketone itself that is halogenated, but the corresponding enol or enolate ion. The purpose of the catalyst is to provide a small amount of enol or enolate (Reaction 12-3). The reaction is often done without addition of acid or base, but traces of acid or base are always present, and these are enough to catalyze formation of the enol or enolate. With acid catalysis the mechanism is

The first step, as seen in Reaction 12-3, actually consists of two steps. The second step is very similar to the first step in electrophilic addition to double bonds (Sec. 15.A.i). There is a great deal of evidence for this mechanism: (1) the rate is first order in substrate; (2) bromine does not appear in the rate expression at all,157 a fact consistent with a rate-determining first step;158 (3) the reaction rate is the same for bromination, chlorination, and iodination under the same conditions;159 (4) the reaction shows an isotope effect; and (5) the rate of the step 2–step 3 sequence has been independently measured (by starting with the enol) and found to be very fast.160

With basic catalysts the mechanism may be the same as that given above (since bases also catalyze formation of the enol), or the reaction may go directly through the enolate ion without formation of the enol:

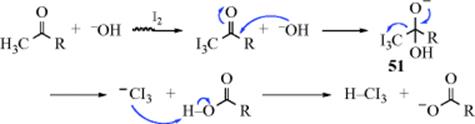

It is difficult to distinguish the two possibilities. It was mentioned above that in the base-catalyzed reaction, if the substrate has two or three α halogens on the same side of the C=O group, it is not possible to stop the reaction after just one halogen atom has entered. The reason is that the electron-withdrawing field effect of the first halogen increases the acidity of the remaining hydrogen atoms; that is, a CHX group is more acidic than a CH2 group, so that the initially formed halo ketone is converted to enolate ion (and hence halogenated) more rapidly than the original substrate. Other halogenating agents can be used in this reaction.

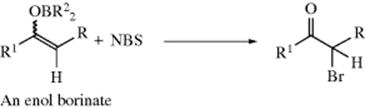

Regioselectivity in the halogenation of unsymmetrical ketones can be attained by treatment of the appropriate enol borinate of the ketone with NBS or NCS.161 The desired halo ketone is formed in high yield. The appropriate lithium enolate can be brominated at a low temperature162 (see Reaction 10-68, category 4 for the regioselective formation of enolate ions). α-Halo aldehydes have been prepared in good yield by treatment of silyl enol ethers (R2C=CHOSiMe3) with Br2 or Cl2,163 with sulfuryl chloride (SO2Cl2),164 or with I2 and silver acetate.165 Silyl enol ethers generate α-chloroketones with good enantioselectivity using ZrCl4 in conjunction with an α,α-dichloromalonate ester.166 Silyl enol ethers can also be fluorinated, with XeF2167 or with 5% F2 in N2 at −78 °C in FCCl3.168 Enol acetates have been regioselectively iodinated with I2 and either Th(I) acetate169 or Cu(II) acetate.170

α,β-Unsaturated ketones can be converted to α-halo-α,β-unsaturated ketones by treatment with phenylselenium bromide or chloride,171 and to α-halo-β,γ-unsaturated ketones by two-phase treatment with HOCl.172 Conjugated ketones were converted to the α-bromo conjugated ketone (a vinyl bromide) using the Dess–Martin periodinane (see Reaction 19-3, category 5) and tetraethylammonium bromide.173

OS I, 127; II, 87, 88, 244, 480; III, 188, 343, 538; IV, 110, 162, 590; V, 514; VI, 175, 193, 368, 401, 512, 520, 711, 991; VII, 271; VIII, 286. See also, OS VI, 1033; VIII, 192.

12-5 Halogenation of Carboxylic Acids and Acyl Halides

Halogenation or Halo-de-hydrogenation

![]()

The α hydrogen atoms of carboxylic acids are replaced by bromine or chlorine using a phosphorus halide as catalyst.174 The reaction, known as the Hell–Volhard–Zelinskii reaction, is not applicable to iodine or fluorine. When there are two α hydrogen atoms, one or both may be replaced, although it is often hard to stop with just one. The reaction actually takes place on the acyl halide formed initially from the carboxylic acid and the halogenating reagent. This means that each molecule of acid is α halogenated while it is in the acyl halide stage. The acids alone are inactive, except for those with relatively high enol content (e.g., malonic acid). Less than one full molar equivalent of catalyst (per molar equivalent of substrate) is required, because of the exchange reaction between carboxylic acids and acyl halides (see Reaction 16-79). The halogen from the catalyst is not transferred to the α position. For example, the use of Cl2 and PBr3 results in α-chlorination, not bromination. As expected from the foregoing, acyl halides undergo a halogenation without a catalyst. An enantioselective α-halogenation was reported to give chiral α-haloesters via an alkaloid-catalyzed reaction of acyl halides with perhaloquinone-derived reagents.175 So do anhydrides and many compounds that enolize easily (e.g., malonic ester and aliphatic nitro compounds). The mechanism is usually regarded as proceeding through the enol as in Reaction 12-4.176 If chlorosulfuric acid (ClSO2OH) is used as a catalyst, carboxylic acids can be α-iodinated,177 as well as chlorinated or brominated.178 N-Bromosuccinimide in a mixture of sulfuric acid–trifluoroacetic acid can monobrominate simple carboxylic acids.179

A number of other methods exist for the α halogenation of carboxylic acids or their derivatives.180 Under electrolytic conditions with NaCl, malonates are converted to 2-chloro malonates.181 Acyl halides can be a brominated or chlorinated by use of NBS or NCS and HBr or HCl.182 The latter is an ionic, not a free radical halogenation (see Reaction 14-3). Direct iodination of carboxylic acids has been achieved with I2-Cu(II) acetate in HOAc.183 Acyl chlorides can be α iodinated with I2 and a trace of HI.184 Carboxylic acids, esters, and amides have been α-fluorinated at −78 °C with F2 diluted in N2.185 Amides have been α-iodinated using iodine and s-collidine.186

OS I, 115, 245; II, 74, 93; III, 347, 381, 495, 523, 623, 705, 848; IV, 254, 348, 398, 608, 616; V, 255; VI, 90, 190, 403; IX, 526. Also see, OS IV, 877; VI, 427.

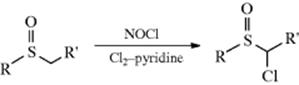

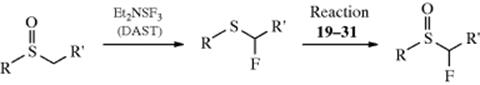

12-6 Halogenation of Sulfoxides and Sulfones

Halogenation or Halo-de-hydrogenation

Sulfoxides can be chlorinated in the α position187 by treatment with Cl2188 or NCS,189 in the presence of pyridine. These methods involve basic conditions. The reaction can also be accomplished in the absence of base with SO2Cl2in CH2Cl2,190 or with TsNCl2.191 The bromination of sulfoxides with bromine192 and with NBS–bromine193 have also been reported. Sulfones have been chlorinated by treatment of their conjugate bases (RSO2C−HR′) with various reagents, among them SO2Cl2, CCl4,194 or NCS.195 The α-fluorination of sulfoxides was reported via treatment with diethylaminosulfur trifluoride (Et2NSF3, DAST) to give an α-fluoro thioether, usually in high yield. Oxidation of this compound with m-chloroperoxybenzoic acid gave the sulfoxide.196

C. Nitrogen Electrophiles

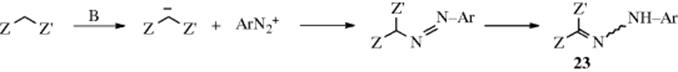

12-7 Aliphatic Diazonium Coupling

Arylhydrazono-de-dihydro-bisubstitution

![]()

If a C–H unit is acidic enough, that carbon couples with diazonium salts in the presence of a base (via the enolate anion), most often aq sodium acetate.197 The reaction is commonly carried out on compounds of the form Z–CH2–Z′, where Z and Z′ are as defined in Section 16-38 (e.g., β-keto esters, β-keto amides, malonic ester).

The mechanism is probably of the simple SE1 type:

Aliphatic azo compounds in which the carbon containing the azo group is attached to a hydrogen are unstable and tautomerize to the isomeric hydrazones (23), which are the products of the reaction.

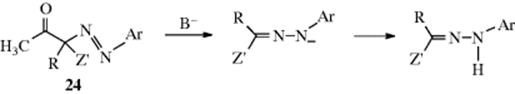

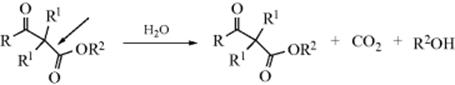

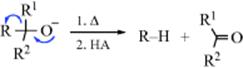

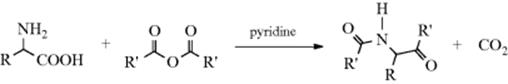

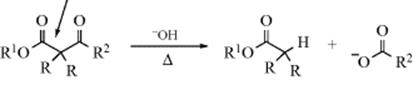

When the reaction is carried out on a compound of the form Z–CHR–Z′, the azo compound does not have a hydrogen that can lead to tautomerism, and at least one Z is acyl or carboxyl, this group usually cleaves:

so the product in this case is also the hydrazone, and not the azo compound. In fact, compounds of the type 24 are seldom isolable from the reaction, although this has been accomplished.198 The cleavage step shown is an example of Reaction 12-43 and, when a carboxyl group cleaves, of Reaction 12-40. The overall process in this case is called the Japp–Klingemann reaction199 and involves conversion of a ketone (25) or a carboxylic acid (26) to a hydrazone (27). When an acyl and a carboxyl group are both present, the leaving group order has been reported to be MeCO > COOH > PhCO.200 When there is no acyl or carboxyl group present, the aliphatic azo compound is stable.

OS III, 660; IV, 633.

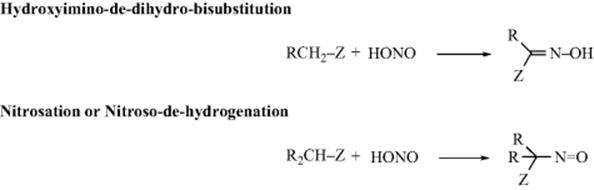

12-8 Nitrosation at a Carbon Bearing an Active Hydrogen

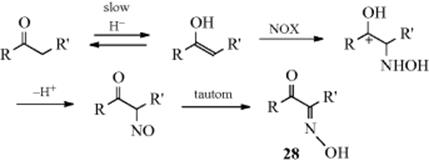

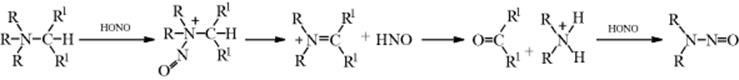

Carbons adjacent to a Z group (as defined in Reaction 10-67) can be nitrosated with nitrous acid or alkyl nitrites.201 The initial product is the C-nitroso compound, but these are stable only when there is no hydrogen that can undergo tautomerism. When there is, the product is the more stable oxime. The situation is analogous to that with azo compounds and hydrazones (Reaction 12-7). The mechanism is similar to that in Reaction 12-7:202 R–H → R− + +N=O → R–N=O. The reactive species is either NO+ or a carrier of it. When the substrate is a simple ketone, the mechanism goes through the enol (as in halogenation Reaction 12-4):

Evidence is that the reaction, in the presence of X− (Br−, Cl−, or SCN−) was first order in ketone and in H+, but zero order in HNO2 and X−.203 Furthermore, the rate of the nitrosation was about the same as that for enolization of the same ketones. The species NOX is formed by HONO + X− + H+ → HOX + H2O. In the cases of F3CCOCH2COCF3 and malononitrile, the nitrosation went entirely through the enolate ion rather than the enol.204

As in the Japp–Klingemann reaction, when Z is an acyl or carboxyl group (in the case of R2CH–Z), it can be cleaved. Since oximes and nitroso compounds can be reduced to primary amines, this reaction often provides a route to amino acids. As in the case of Reaction 12-4, the silyl enol ether of a ketone can be used instead of the ketone itself.205 Good yields of α-oximinoketones (28) can be obtained by treating ketones with tert-butyl thionitrate.206

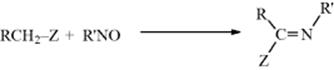

Imines can be prepared in a similar manner by treatment of an active hydrogen compound with a nitroso compound:

Alkanes can be nitrosated photochemically, by treatment with NOCl and UV light.207 For nitration at an activated carbon, see Reaction 12-9. Trialkyltin enol ethers (C=C–O–SnR3) react with PhNO to give α-(N-hydroxylamino)ketones.208

OS II, 202, 204, 223, 363; III, 191, 513; V, 32, 373; VI, 199, 840. Also see, OS V, 650.

12-9 Nitration of Alkanes

Nitration or Nitro-de-hydrogenation

![]()

Nitration of alkanes209 can be carried out in the gas phase at ~400 °C or in the liquid phase. The reaction is not practical for the production of pure products for any alkane except methane. For other alkanes, not only does the reaction produce mixtures of the mono-, di-, and polynitrated alkanes at every combination of positions, but extensive chain cleavage occurs.210 A free radical mechanism is involved.211

![]()

Activated positions (e.g., ZCH2Z′ compounds) can be nitrated by fuming nitric acid in acetic acid, by acetyl nitrate and an acid catalyst,212 or by alkyl nitrates under alkaline conditions.213 In the latter case, it is the carbanionic form of the substrate that is actually nitrated. The conjugate base of the nitro compound is isolated under these alkaline conditions, but yields are not high. Of course, the mechanism in this case is not of the free radical type, but is electrophilic substitution with respect to the carbon (similar to the mechanisms of Reactions 12-7 and 12-8). Positions activated by only one electron-withdrawing group (e.g., α positions of simple ketones, nitriles, sulfones, or N,N-dialkyl amides) can be nitrated with alkyl nitrates if a very strong base (e.g., t-BuOK or NaNH2,) is present to convert the substrate to the carbanionic form.214

Electrophilic nitration of alkanes has been performed with nitronium salts (e.g., NO2+ PF6− and with HNO3–H2SO4 mixtures), but mixtures of nitration and cleavage products are obtained and yields are generally low.215 The reaction of alkanes with nitric acid and N-hydroxysuccinimide (NHS), however, gave moderate-to-good yields of the corresponding nitroalkane.216 Similar nitration was accomplished with NO2, NHS and air.217 Aliphatic nitro compounds can be a nitrated [R2C-NO2 → R2C(NO2)2] by treatment of their conjugate bases RCNO2 with NO2− and K3Fe(CN)6.218

OS I, 390; II, 440, 512.

12-10 Direct Formation of Diazo Compounds

Diazo-de-dihydro-bisubstitution

![]()

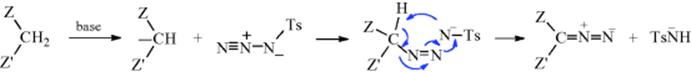

Compounds containing a CH2 bonded to two Z groups (active methylene compounds, with Z as defined in Reaction 10-67) can be converted to diazo compounds on treatment with tosyl azide in the presence of a base.219 The use of phase-transfer catalysis increases the convenience of the method.220 Sulfonyl azides also give the reaction.221 The diazo-transfer reaction can also be applied to other reactive positions (e.g., the 5 position of cyclopentadiene).222The mechanism is probably as follows:

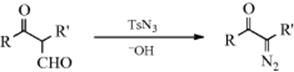

A diazo group can be introduced adjacent to a single carbonyl group indirectly by first converting the ketone to an α-formyl ketone (Reaction 16-85) and then treating it with tosyl azide. As in the similar cases of Reactions 12-7and 12-8, the formyl group is cleaved during the reaction.223

OS V, 179; VI, 389, 414.

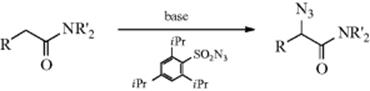

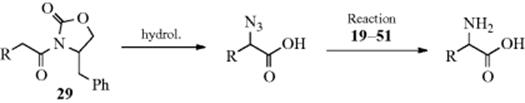

12-11 Conversion of Amides to α-Azido Amides

Azidation or Azido-de-hydrogenation

In Reaction 12-10, treatment of Z–CH2–Z′ with tosyl azide gave the α-diazo compound via diazo transfer. When this reaction is performed on a compound with a single Z group (e.g., an amide), formation of the azide becomes a competing process via the enolate anion.224 Factors favoring azide formation rather than diazo transfer include K+ as the enolate counterion rather than Na+ or Li+ and the use of 2,4,6-triisopropylbenzenesulfonyl azide rather than TsN3. When the reaction was applied to amides with a chiral R′ (e.g., the oxazolidinone derivative 29), it was highly stereoselective, and the product could be converted to an optically active amino acid.224

12-12 Direct Amination at an Activated Position

Alkyamino-de-hydrogenation, and so on

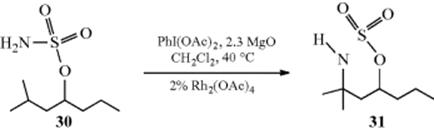

Alkenes can be aminated225 in the allylic position by treatment with solutions of imido selenium compounds (R–N=Se=N–R).226 The reaction, which is similar to the allylic oxidation of alkenes with SeO2 (see Reaction 19-14), has been performed with R = t-Bu and R = Ts. The imido sulfur compound TsN=S=NTs has also been used,227 as well as PhNHOH–FeCl2/FeCl3.228 Benzylic positions can be aminated with t-BuOOCONHTs in the presence of a catalytic amount of Cu(OTf)2.229 Enantioselective allylic amination has been reported using organocatalyts.230 A Rh catalyzed amination of benzylic positions has also been reported.231

Tertiary alkyl hydrogen can be replaced in some cases via C–H nitrogen insertion. The reaction of sulfamate ester (30) with PhI(OAc)2, MgO, and a dinuclear Rh carboxylate catalyst, for example, generated oxathiazinane (31).232This transformation is a formal oxidation, and primary carbamates have been similarly converted to oxazolidin-2-ones.233

Amination of 1,3-dicarbonyl compounds can be done using functionalized dimides and an appropriate catalyst, generating the corresponding hydrazone. Enantioselective amination using this method has been reported, using a chiral guanidine catalyst.234

See also, Reaction 10-39.

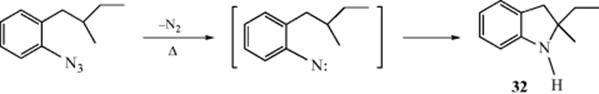

12-13 Insertion by Nitrenes

CH-[Acylimino]-insertion, and so on

Carbonylnitrenes (:NCOW, W = R′, Ar, or OR′) are very reactive species (Sec. 5.E) and insert into the C–H bonds of alkanes to give amides (W = R′ or Ar) or carbamates (W = OR′).235 The nitrenes are generated as discussed in Section 5.E. The order of reactivity among alkane C–H bonds is tertiary > secondary > primary.236 Nitrenes are much more selective (and less reactive) in this reaction than carbenes (Reaction 12-17).237 It is likely that only singlet and not triplet nitrenes insert.238 Retention of configuration is found at a stereogenic carbon.239 The mechanism is presumably similar to the simple one-step mechanism for insertion of carbenes (Reaction 12-21). Other nitrenes [e.g., cyanonitrene (NCN)240 and arylnitrenes (NAr)241] can also insert into C–H bonds, but alkylnitrenes usually undergo rearrangement before they can react with the alkane. The Au(III) catalyzed insertion of nitrenes into aromatic and benzylic C–H groups has been reported.242 N-Carbamoyl nitrenes undergo insertion reactions that often lead to mixtures of products, but exceptions are known,243 chiefly in cyclizations.244 For example, heating of 2-(2-methylbutyl)phenyl azide gave ~60% 2-ethyl-2-methylindoline (32).239 Enantioselective nitrene insertion reactions are known.245

D. Sulfur Electrophiles

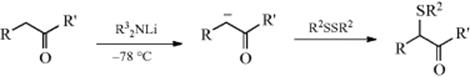

12-14 Sulfenylation, Sulfonation, and Selenylation of Ketones and Carboxylic Esters

Alkylthio-de-hydrogenation, and so on

Sulfonation or Sulfo-de-hydrogenation

Ketones, carboxylic esters (including lactones),246 and amides (including lactams)247 can be sulfenylated248 in the α position by conversion to the enolate anion (see Sec. 8.F, part 7), and subsequent treatment with a disulfide.249The reaction, shown above for ketones, involves nucleophilic substitution at sulfur. α-Phenylseleno ketones [RCH(SePh)COR′] and α-phenylseleno esters [RCH(SePh)COOR′] can be similarly prepared250 by treatment of the corresponding enolate anions with PhSeBr,251 PhSeSePh,252 or benzeneseleninic anhydride [PhSe(O)OSe(O)Ph].253 Another method for the introduction of a phenylseleno group into the α position of a ketone involves simple treatment of an ethyl acetate solution of the ketone with PhSeCl (but not PhSeBr) at room temperature.254 This procedure is also successful for aldehydes but not for carboxylic esters. N-Phenylselenophthalimide has been used to convert ketones255 and aldehydes256 to the α- PhSe derivative. Silyl enol ethers are converted to α-alklylthio and α-arylthio ketones via a sulfenylation method, driven by aromatization of an added quinone mono-O,S-acetal in the presence of Me3SiOTf.257

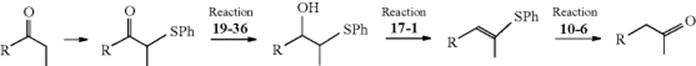

The α-seleno and α-sulfenyl carbonyl compounds prepared by this reaction can be converted to α,β-unsaturated carbonyl compounds (Reaction 17-12). The sulfenylation reaction has also been used258 as a key step in a sequence for moving the position of a carbonyl group to an adjacent carbon.259

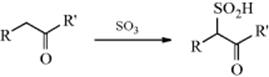

Aldehydes, ketones, and carboxylic acids containing α hydrogen atoms can be sulfonated with sulfur trioxide.260 The mechanism is presumably similar to that of Reaction 12-4. Sulfonation has also been accomplished at vinylic hydrogen.

OS VI, 23, 109; VIII, 550. OS IV, 846, 862.

E. Carbon Reagents

12-15 Alkylation and Alkenylation of Alkenes

Alkylation or Alkyl-de-oxysulfonation (de-halogenation), Arylation or Aryl-de-oxysulfonation (de-halogenation), and so on

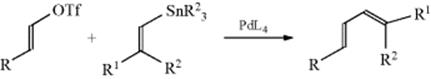

Vinyl triflates (C=C–OSO2CF3) react with vinyl tin derivatives in the presence of Pd catalysts to form dienes, in what is known as Stille coupling.261 Phosphine or bis(phosphine) ligands are most commonly used with the Pd catalyst,262 but other ligands have been used,263 including triphenylarsine.264 Vinyl triflates can be prepared from the enolate anion by reaction with N-phenyl triflimide.265 Vinyltin compounds are generally prepared by the reaction of an alkyne with an trialkyltin halide (see Reactions 15-17 and 15-21).266 Stille cross-coupling reactions are an important variation of the basic reaction,267 including cross-coupling reactions of unactivated secondary halides and monoorganotin reagents.268 Stille reactions are compatible with many functional groups. Vinyl halides can be used,269 and allenic tin compounds have been used.270 Intramolecular reactions are possible.271 Stille coupling has been done using microwave irradiation,272 in fluorous solvents,273 and in supercritical carbon dioxide (see Sec. 9.D.ii).274 Stille coupling using alkynes as a substrate are known.275

This reaction is highly stereoselective, and proceeds with a retention of geometry of the C=C units, and are usually regiospecific with respect to the newly formed C–C σ-bond. Cine substitution is known with this reaction, and its mechanism has been studied.276 Using ArSnCl3 derivatives, Stille coupling can be done in aq KOH.277

Aryl halides,278 heteroaryl halides,279 and heteroaryl triflates280 can be coupled to vinyltin reagents281 using a Pd catalyst. A Mo catalyzed variation is known.282 A Cu catalyzed cross coupling variation283 has been reported in ionic liquids.284 Vinyl halides can be coupled to alkenes to form dienes.285 The reaction of dihydrofurans with vinyl triflates and a Pd catalyst leads to a nonconjugated diene,286 illustrating that the product is formed by an elimination step, as with the Heck reaction (13-10), and double-bond migration can occur resulting in allylic rearrangement.

The accepted mechanism for the Stille reaction involves a catalytic cycle287 in which an oxidative addition288 and a reductive elimination step289 are fast, relative to Sn/Pd transmetalation (the rate-determining step).290 It appears that the greater the coordinating ability of the unsaturated species is important, and a coordinated solvent molecule is likely involved in the electrophilic substitution at tin. Another mechanism has been proposed, in which oxidative addition of the vinyl triflate to the ligated Pd gives a cis-Pd complex that isomerizes rapidly to a trans-Pd complex, which then reacts with the organotin compound following an SE2 (cyclic) mechanism, with release of a ligand.291This pathway gives a bridged intermediate, and subsequent elimination of XSnBu3 yields a three-coordinate species cis-Pd complex, which readily gives the coupling product.291 Most of the major intermediates have been intercepted, isolated, and characterized using electrospray ionization mass spectrometry.292

Cyclopropylboronic acids (Reaction 12-28) couple with vinylic halides293 or vinyl triflates294 to give vinylcyclopropanes, using a Pd catalyst. Vinyl borates (Reaction 12-28) were coupled to vinyl triflates using a Pd catalyst.295Vinyltrifluoroborates can be coupled to allylic chlorides using microwave irradiation296 and vinyl halides react with vinyltrifluoroborates to give dienes with high stereoselectivity.297 Stille coupling to enols has been reported.298 The coupling of vinyl silanes to give the symmetrically conjugated diene using CuCl and air has also been reported.299

Other methods are available to give Stille-like products. 1-Lithioalkynes were coupled to vinyl tellurium compounds (C=C–TeBu) using a Ni300 or a Pd catalyst301 to give a conjugated en-yne. 2-Alkynes (R–C![]() C–Me) react with HgCl2, n-butyllithium, and ZnBr2, sequentially, and then with vinyl iodides and a Pd catalyst to give the nonconjugated en-yne.302 Alkynyl groups can be coupled to vinyl groups to give ene-ynes, via reaction of silver alkynes (Ag–C

C–Me) react with HgCl2, n-butyllithium, and ZnBr2, sequentially, and then with vinyl iodides and a Pd catalyst to give the nonconjugated en-yne.302 Alkynyl groups can be coupled to vinyl groups to give ene-ynes, via reaction of silver alkynes (Ag–C![]() C–R) with vinyl triflates and a Pd catalyst.303 In the presence of CuI and a Pd catalyst, vinyl triflates304 or vinyl halides305 couple to terminal alkynes. Alkynyl zinc reagents (R–C

C–R) with vinyl triflates and a Pd catalyst.303 In the presence of CuI and a Pd catalyst, vinyl triflates304 or vinyl halides305 couple to terminal alkynes. Alkynyl zinc reagents (R–C![]() C–ZnBr) can be coupled to vinyl halides with a Pd catalyst to give the conjugated en-yne.306

C–ZnBr) can be coupled to vinyl halides with a Pd catalyst to give the conjugated en-yne.306

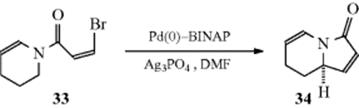

Alkyl groups can be coupled to a vinyl unit to give substituted alkenes. The reaction of vinyl iodides and EtZnBr, with a Pd catalyst, gave the ethylated alkene (C=C–Et).307 Aliphatic alkyl bromides reacted with vinyltin compounds to give the alkylated alkene using a Pd catalyst.308 Allylic tosylates were coupled to conjugated alkenes to give a non-conjugated diene using a Pd catalyst.309 An internal coupling reaction was reported in which an alkenyl enamide (33) reacted with Ag3PO4 and a chiral palladium catalyst to give 34 enantioselectively.310

For the related coupling reaction of alkenes and aryl compounds (arylation of alkenes), see Reaction 13-10.

12-16 Acylation at an Aliphatic Carbon

Acylation or Acyl-de-hydrogenation

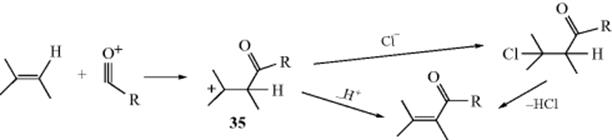

Alkenes can be acylated with an acyl halide and a Lewis acid catalyst in what is essentially a Friedel–Crafts Reaction (11-17) at an aliphatic carbon.311 The product can arise by two paths. The initial attack is by the π bond of the alkene unit on the acyl cation (RCO+; or on the acyl halide free or complexed; see Reaction 11-17) to give a carbocation, (35).

Ion 35 can either lose a proton or combine with chloride ion. If it loses a proton, the product is an unsaturated ketone. The mechanism is similar to the tetrahedral mechanism in Section 16.A.i, but with the charges reversed. If it combines with chloride, the product is a β-halo ketone, which can be isolated, so that the result is addition to the double bond (see Reaction 15-47). On the other hand, the β-halo ketone may, under the conditions of the reaction, lose HCl to give the unsaturated ketone, this time by an addition–elimination mechanism. In the case of unsymmetrical alkenes, the more stable alkene is formed (the more highly substituted and/or conjugated alkene, following Markovnikov's rule, see Sec. 15.B.ii). Anhydrides and carboxylic acids (the latter with a proton acid e.g., anhydrous HF, H2SO4, or polyphosphoric acid as a catalyst) are sometimes used instead of acyl halides. With some substrates and catalysts, double-bond migrations are occasionally encountered so that, for example, when 1-methylcyclohexene was acylated with acetic anhydride and zinc chloride, the major product was 6-acetyl-1-methylcyclohexene.312

Conjugated dienes can be acylated by treatment with acyl- or alkylcobalt tetracarbonyls, followed by base-catalyzed cleavage of the resulting π-allyl carbonyl derivatives313 (π-allyl metal complexes were discussed in Sec. 3.C.i. The reaction is very general. With unsymmetrical dienes, the acyl group generally substitutes most readily at a cis double bond, next at a terminal alkenyl group, and least readily at a trans double bond. The most useful bases are strongly basic, hindered amines (e.g., dicyclohexylethylamine). Acylation of vinylic ethers has been accomplished with aromatic acyl chlorides, a base, and a Pd catalyst: ROCH=CH2 → ROCH=CHCOAr.314

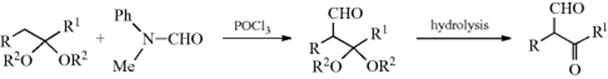

Formylation of alkenes can be accomplished with N-disubstituted formamides and POCl3.315 This is an aliphatic Vilsmeier reaction (see Reaction 11-18). Vilsmeier formylation can also be performed on the α position of acetals and ketals, so that hydrolysis of the products gives keto aldehydes or dialdehydes:316 A variation heated a 1,1-dibromoalkene with a secondary amine in aq DMF to give the corresponding amide.317

Acetylation of acetals or ketals can be accomplished with acetic anhydride and BF3–etherate.318 The mechanism with acetals or ketals also involves attack at an alkenyl carbon, since enol ethers are intermediates.318 Ketones can be formylated in the α position by treatment with CO and a strong base.319

OS IV, 555, 560; VI, 744. Also see, OS VI, 28.

12-17 Conversion of Enolates to Silyl Enol Ethers, Silyl Enol Esters, and Silyl Enol Sulfonate Esters

3/O-Trimethylsilyl-de-hydrogenation

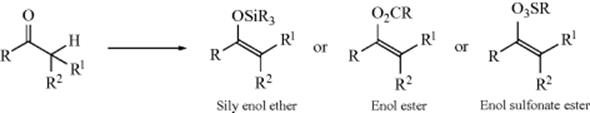

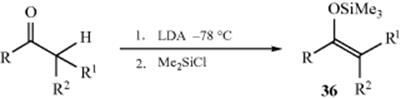

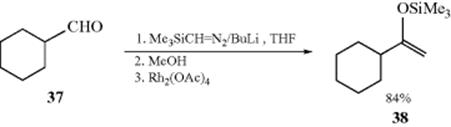

Silyl enol ethers,320 important reagents with a number of synthetic uses (see, e.g., Reactions 10-68, 12-4, 15-24, 15-64, and 16-36), can be prepared by base treatment of a ketone (converting it to its enolate anion) followed by addition of a trialkylchlorosilane. Other silylating agents have also been used.321 Both strong bases (e.g., LDA), and weaker bases (Et3N) have been used for this purpose.322 In some cases, the base and the silylating agent can be present at the same time.323 Enolate anions prepared in other ways (e.g., as shown in Reaction 10-58) also give the reaction.324 The reaction can be applied to aldehydes by the use of the base KH in 1,2-dimethoxyethane.325 A particularly mild method for conversion of ketones or aldehydes to silyl enol ethers uses Me3SiI and the base hexamethyldisilazane [(Me3Si)2NH.]326 Cyclic ketones can be converted to silyl enol ethers in the presence of acyclic ketones, by treatment with Me3SiBr, tetraphenylstibonium bromide (Ph4SbBr), and an aziridine.327 bis(Trimethylsilyl)acetamide is an effective reagent for the conversion of ketones to the silyl enol ether, typically giving the thermodynamic product (see below).328 Silyl enol ethers have also been prepared by the direct reaction of a ketone and a silane (R3SiH) with a Pt catalyst.329

For substituted ketones, (E) and (Z) isomers are usually formed. For 36, the enol is (Z) when R1 is the priority group, but (E) when R2 is the priority group. In some cases, it is possible to control the selectivity to favor more of one isomer than the other. Treatment of 2-methyl-3-pentanone with LDA (THF, -78 °C), for example, gave a 60:40 mixture of the (Z) and (E) enolates.330 The base used to generate an enolate anion, the solvent and temperature, the conjugate acid of the base used, and the nature of the carbonyl substrate will all play a role in the selectivity. In general, equilibrating (thermodynamic) conditions [protic solvents (e.g., ethanol, water, or ammonia), a base generating a conjugate acid stronger than the starting ketone, more ionic counterions (e.g., K or Na), higher temperatures and longer reaction times] are expected to give more of the (E)-isomer. Conversely, kinetic conditions [aprotic solvents (e.g., ether or THF), a base generating a conjugate acid weaker than the starting ketone, more covalent counterions (e.g., Li, lower temperatures), and relatively short reaction times] usually give more of the (Z)-isomer. It is not always easy to predict the ratio, however. Either isomer is possible from aldehydes using the proper Rh catalyst.331

Magnesium diisopropylamide has been used to prepare kinetic silyl enol ethers in virtual quantitative yield.332 Reaction with Me3SiCl/KI in DMF gives primarily the thermodynamic silyl enol ether.333

An interesting synthesis of silyl enol ethers involves chain extension of an aldehyde. Aldehydes are converted to the silyl enol ether of a ketone upon reaction with lithium (trimethylsilyl)diazomethane and then a dirhodium catalyst.334 For example, initial reaction of lithium(trimethylsilyl)diazomethane [LTMSD, prepared in situ by reaction of butyllithium with (trimethylsilyl)diazomethane] to the aldehyde (e.g., 37) gave the alkoxide addition product. Protonation and then capture by a transition metal catalyst, and a 1,2-hydride migration gave the silyl enol ether, (38). Silyl enol ethers can be prepared from acyloin derivatives (see Reaction 19-78).335

Enol acetates are generally prepared by the reaction of an enolate anion with a suitable acylating reagent.336 Enolate anions react with acyl halides and with anhydrides to give the acylated product. Both C- and O-acylation are possible, but in general O-acylation predominates.337 Note that the extent of O- versus C-acylation is very dependent on the local environment and electronic effects within the enolate anion.338 O-Benzoate enols are formed in good yield from aldehydes or 1,3-diketones in the presence of CuBr and tert-butylhydroperoxide.339 Silyl sulfonate esters can be prepared by similar methods, using sulfonic acid anhydrides rather than carboxylic anhydrides. A polymer-supported triflating agent was used to prepare silyl enol triflate from ketones, in the presence of diisopropylethylamine.340

When a silyl enol ether is the trimethylsilyl derivative (Me3Si–O-C=C), treatment with methyllithium will regenerate the lithium enolate anion and the volatile trimethylsilane (Me3SiH).341

OS VI, 327, 445; VII, 282, 312, 424, 512; VIII, 1, 286, 460; IX, 573. See also, OS VII, 66, 266. For the conversion of ketones to vinylic triflates,342 see OS VIII, 97, 126.

12-18 Conversion of Aldehydes to β-Keto Esters or Ketones

Alkoxycarbonylalkylation or Alkoxycarbonylalkyl-de-hydrogenation

![]()

β-Keto esters have been prepared in moderate to high yields by treatment of aldehydes with diethyl diazoacetate in the presence of a catalytic amount of a Lewis acid (e.g., SnCl2, BF3, or GeCl2).343 The reaction was successful for both aliphatic and aromatic aldehydes, but the former react more rapidly than the latter, and the difference is great enough to allow selective reactivity. In a similar process, aldehydes react with certain carbanions stabilized by boron, in the presence of (F3CCO)2O or NCS, to give ketones.344

Ketones can be prepared from aryl aldehydes (ArCHO) by treatment with a Rh complex [(Ph3P)2Rh(CO)Ar′], whereby the Ar group is transferred to the aldehyde, producing the ketone (Ar–CO–Ar′).345 In another Rh catalyzed reaction, aryl aldehydes (ArCHO) react with Me3SnAr′ to give the diaryl ketone (Ar–CO–Ar′).346

Acylation of aryl halides with aldehydes gives arylketones in the presence of a Pd catalyst.347

12-19 Cyanation or Cyano-de-hydrogenation

![]()

There are several reactions in which a C–H unit is replaced by C–CN. In virtually all cases, the hydrogen being replaced is on a carbon α to a heteroatom or functional group. There are several examples.

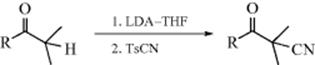

Introduction of a cyano group α to the carbonyl group of a ketone can be accomplished by prior formation of the enolate anion with LDA in THF and addition of this solution to p-TsCN at −78 °C.348 The products are formed in moderate to high yields but the reaction is not applicable to methyl ketones. Treatment of TMSCH2N(Me)C=Nt-Bu with sec-butyllithium and R2C=O, followed by iodomethane and NaOMe leads to the nitrile (R2CH–CN).349

Cyanation has been shown to occur α to a nitrogen, specifically in N,N-dimethylaniline derivatives. Treatment with a catalytic amount of RuCl3 in the presence of oxygen and NaCN leads to the corresponding cyanomethylamine.350 Conversion of tertiary amines to the α-cyanoamine has been reported in the presence of FeCl2 and t-BuOOH.351

In a different kind of reaction, nitro compounds are α-cyanated by treatment with −CN and K3Fe(CN)6.352 The mechanism probably involves ion radicals. In still another reaction, secondary amines are converted to α-cyanoamines by treatment with phenylseleninic anhydride and NaCN or Me3SiCN.353,354

Another specialized reaction converts the methyl group of arenes (e.g., toluene) into a cyano group: toluene → benzonitrile, for example.355

12-20 Alkylation of Alkanes

Alkylation or Alkyl-de-hydrogenation

![]()

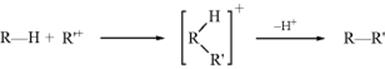

Alkanes can be alkylated by treatment with solutions of stable carbocations356 (Sec. 5.A.ii), but the availability of such carbocations is limited and mixtures are usually obtained. In a typical experiment, the treatment of propane with isopropyl fluoroantimonate (Me2HC+ SbF6−) gave 26% 2,3-dimethylbutane, 28% 2-methylpentane, 14% 3-methylpentane, and 32% n-hexane, as well as some butanes, pentanes (formed by Reaction 12-47), and higher alkanes. Mixtures arise in part because intermolecular hydrogen exchange (RH + R′+ → R+ + R′H) is much faster than alkylation, so that alkylation products are also derived from the new alkanes and carbocations formed in the exchange reaction. Furthermore, the carbocations present are subject to rearrangement (Chapter 18), giving rise to new carbocations. Products result from all the hydrocarbons and carbocations present in the system. As expected from their relative stabilities, secondary alkyl cations alkylate alkanes more readily than tertiary alkyl cations (the tert-butyl cation does not alkylate methane or ethane). Stable primary alkyl cations are not available, but alkylation has been achieved with complexes formed between CH3F or C2H5F and SbF5.357 The mechanism of alkylation can be formulated (similar to that shown in hydrogen exchange with superacids, Reaction 12-1) as

It is by means of successive reactions of this sort that simple alkanes like methane and ethane give tert-butyl cations in superacid solutions (Sec. 5.A.ii).358

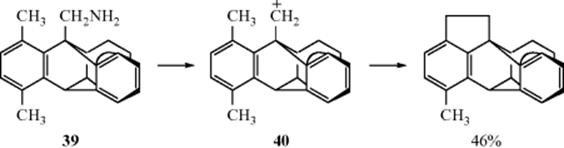

Intramolecular insertion has been reported. The positively charged carbon of the carbocation (40), generated from the diazonium salt of the triptycene compound (39), reacted with the CH3 group in close proximity with it.359

12-21 Insertion by Carbenes

CH-Methylene-insertion

![]()

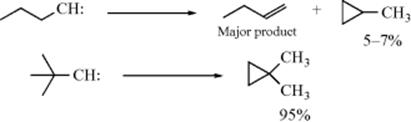

The highly reactive species methylene (:CH2) inserts into C–H bonds,360 both aliphatic and aromatic,361 although with aromatic compounds subsequent ring expansion is also possible (see Reaction 15-64). This is effectively a homologation reaction.362 The methylene insertion reaction has limited utility because of its nonselectivity (see Sec. 5.D.i). The insertion reaction of carbenes has been used for synthetic purposes.363

The carbenes can be generated in any of the ways mentioned in Chapter 5 (Sec. 5.D.ii). Alkylcarbenes usually rearrange rather than give insertion (Sec. 5.D.ii, category 4), but, when this is impossible, intramolecular insertion364 is found rather than intermolecular.365 Methylene (:CH2) generated by photolysis of diazomethane (CH2N2) in the liquid phase is indiscriminate (totally nonselective) in its reactivity (Sec. 5.D.ii, category 2). Methylene (:CH2) generated in other ways and monoalkyl and dialkyl carbenes are less reactive and insert in the order tertiary > secondary > primary.366 Carbene insertion with certain allylic systems can proceed with rearrangement of the double bond.367 Carbenes have been generated using ultrasound.368 Halocarbenes (:CCl2,:CBr2, etc.) insert much less readily, although a number of instances have been reported.369

Insertion at an allylic carbon of alkenes has been reported.370 Dirhodium catalyzed insertion into H–Csp2 bonds is known,371 and also H–Csp bonds.372 Note that cyclopropanation may compete with C–H insertion with electron-rich highly substituted alkenes.373 Palladacycles formed by C–H insertion reactions with biphenylene have been intercepted.374 Such species have been impicated in the Heck reaction (Reaction 13-10). Insertion of diazoalkane and diazocarbonyl compounds can be catalyzed by copper compounds375 and silver compounds376 as well. Insertion into the α-C–H bond of an aldehyde gives an α-substituted aldehyde.377 Intramolecular insertion at the α carbon of a ketone by a diazoketone, using TiCl4, gives a bicyclic 1,3-diketone.378 The reaction in which aldehydes are converted to methyl ketones, RCHO + CH2N2 → RCOCH3, while apparently similar, does not involve a free carbene intermediate and is considered in Reaction 18-9. Note that aryl ketenes react with Me3SiCHN2 and then silica to give 2-indanone derivatives.379 A three component coupling reaction of vinyl iodides, secondary amines, and diazo(trimethylsilyl)methane gives allylic amines.380 A gold-catalyzed reaction is known that uses alkynes as an α-diazo ketone equivalent.381

Insertion into the O–H bond of alcohols, to produce ethers, has been reported using a diazocarbonyl compound and an In(OTf)3 catalyst.382 The Cu catalyzed insertion of a diazo ester into an oxetane gives the ring-expanded THF derivative.383 Insertion is also possible with other ethers, including silyl ethers.384 Metal-catalyzed silylene insertion into allylic ethers leads to allylic silanes.385 Similar insertion at the α carbon of an ether leads to cyclic ethers, with high enantioselectivity when a chiral ligand is used with a Rh catalyst.386

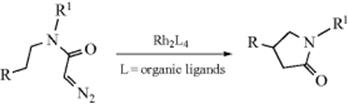

The insertion of the diazocarbonyl unit into the C–H bond of an α-diazo amide gives the lactam shown in the reaction.387 Insertion into a 2-pyrrolidinone derivative using Me3SiCH2N2 followed by AgCO2Ph with ultrasound gave the ring-expanded 2-piperidone derivative.388 Intramolecular insertion reactions are well known,389 and tolerate a variety of functional groups.390

The metal carbene insertion reaction, in contrast to the methylene insertion reaction can be highly selective391 and useful in synthesis.392 There are numerous examples, usually requiring a transition metal catalyst.393 The catalyst typically converts a diazoalkane or diazocarbonyl compound to the metal carbene in situ, allowing the subsequent insertion reaction. Intermolecular reactions are known, including diazoalkane insertion reaction with a dirhodium catalyst.394 When chiral ligands are present good enantioselectivity is observed in the insertion product.395

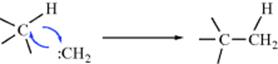

The mechanism396 of the insertion reaction is not known with certainty, but there seem to be at least two possible pathways.

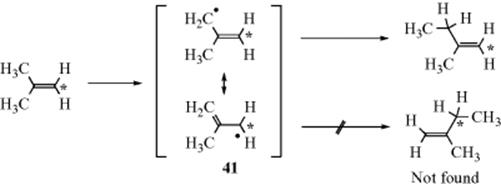

1. A simple one-step process involving a three-center cyclic transition state:

The most convincing evidence for this mechanism is that in the reaction between isobutene-1![]() and carbene the product 2-methyl-1-butene was labeled only in the 1 position.397 This rules out a free radical or a carbocation or carbanion intermediate. If 41 (or a corresponding ion) were an intermediate, resonance would ensure that some carbene attacked at the 1 position:

and carbene the product 2-methyl-1-butene was labeled only in the 1 position.397 This rules out a free radical or a carbocation or carbanion intermediate. If 41 (or a corresponding ion) were an intermediate, resonance would ensure that some carbene attacked at the 1 position:

Other evidence is that retention of configuration, which is predicted by this mechanism, has been found in a number of instances.398 An ylid intermediate was trapped in the reaction of :CH2 with allyl alcohol.399

2. A free radical process in which the carbene directly abstracts a hydrogen from the substrate to generate a pair of free radicals:

![]()

One fact supporting this mechanism is that among the products obtained (beside butane and isobutane) on treatment of propane with CH2 (generated by photolysis of diazomethane and ketene) were propene and ethane,400which could arise, respectively, by

![]()

and

![]()

That this mechanism can take place under suitable conditions has been demonstrated by isotopic labeling401 and by other means.402 However, the formation of disproportionation and dimerization products does not always mean that the free radical abstraction process takes place. In some cases, these products arise in a different manner.403 The product of the reaction between a carbene and a molecule may have excess energy (see Sec. 5.D.ii). Therefore it is possible for the substrate and the carbene to react by mechanism 1 (the direct-insertion process) and for the excess energy to cause the compound thus formed to cleave to free radicals. When this pathway is in operation, the free radicals are formed after the actual insertion reaction.

The mechanism of cyclopropylcarbene reactions has also been discussed.404

It has been suggested405 that singlet carbenes insert by the one-step direct-insertion process and triplets (which, being free radicals, are more likely to abstract hydrogen) by the free radical process. In support of this suggestion, CIDNP signals406 (Sec. 5.C.i) were observed in the ethylbenzene produced from toluene and triplet CH2, but not from the same reaction with singlet CH2.407 Carbenoids (e.g., compounds of the form R2CMCl, see Reaction 12-39) can insert into a C–H bond by a different mechanism, similar to pathway 2, but involving abstraction of a hydride ion rather than a hydrogen atom.408

For the similar insertion reaction of nitrenes, see Reaction 12-13.

OS VII, 200.

F. Metal Electrophiles

12-22 Metalation with Organometallic Compounds

Metalation or Metalo-de-hydrogenation

![]()

Many organic compounds can be metalated by treatment with an organometallic compound.409 Since the reaction involves a proton transfer, the equilibrium lies on the side of the weaker acid.410 For example, fluorene reacts with n-butyllithium to give butane and 9-fluorenyllithium. Since aromatic hydrocarbons are usually stronger acids than aliphatic ones, R is most often aryl. The most common reagent is probably butyllithium.411 Reductive lithiation is an important method for the preparation of organolithium reagents.412 Normally, only active aromatic rings react with butyllithium. Benzene itself reacts very slowly and in low yield, although benzene can be metalated by butyllithium either in the presence of tert-BuOK413 or by n-butyllithium that is coordinated with various diamines.414 Metalation of aliphatic RH is most successful when the carbanions are stabilized by resonance (allylic, benzylic, propargylic,415 etc.) or when the negative charge is at an sp carbon (at triple bonds). Trimethylsilylmethyl potassium (Me3SiCH2K)416 and also a combination of an organolithium compound with a bulky alkoxide (LICKOR superbase)417 are very good reagents for allylic metalation. The former is also useful for benzylic positions. A combination of BuLi, t-BuOK, and tetramethylethylenediamine has been used to convert ethylene to vinylpotassium.418The reaction can be used to determine relative acidities of very weak acids by allowing two R–H compounds to compete for the same R′M and to determine which proton in a molecule is the most acidic.419

Note that organolithium compounds are aggregated species and can form hetero-aggregates containing different organic groups.420 N-Lithio-N-(trialkylsilyl)allylamines are deprotonated in ether solvents at the cis-vinylic position to give 3,N-dilithio-N-(trialkylsilyl)allylamines.421

In general, the reaction can be performed only with organometallics of active metals (e.g., Li, Na, and K), but Grignard reagents abstract protons from a sufficiently acidic C–H bond, as in R–C![]() C–H → R–C

C–H → R–C![]() C–MgX. This is the best method for the preparation of alkynyl Grignard reagents.422 Lewis acids have been used to promote α-lithiation of amines.423 Triethylgallium has been used to generate enolate anions from ketones.424

C–MgX. This is the best method for the preparation of alkynyl Grignard reagents.422 Lewis acids have been used to promote α-lithiation of amines.423 Triethylgallium has been used to generate enolate anions from ketones.424

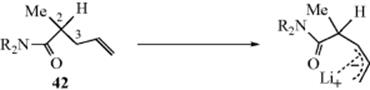

When a heteroatom (e.g., N, O, S,425 or a halogen),426 is present in a molecule containing an aromatic ring or a double bond, lithiation is usually quite regioselective.427 It has been shown that fluorine is more effective for stabilization of carbanions when compared to the heavier halogens.428 In such compounds, the lithium usually bonds with the sp2 carbon closest to the heteroatom, probably because the attacking species coordinates with the heteroatom.429 This type of reaction with compounds such as anisole are often called directed metalations.430 In the case of aromatic rings, this means attack at the ortho position,431 but this is considered in Reaction 13-17.

![]()

Ref. 432

In the case of γ,δ-unsaturated disubstituted amides (42), the lithium does not go to the closest position, but in this case too the regiochemistry is controlled by coordination to the oxygen.433 Cyclopropyllithium reagents are rather stable.434

The mechanism involves an attack by R′− (or a polar R′) on the hydrogen435 (an acid–base reaction) Evidence is that resonance effects of substituents in R seem to make little difference. When R is aryl, OMe and CF3 both direct ortho, while isopropyl directs meta and para (mostly meta).436 These results are exactly what would be expected from pure field effects, with no contribution from resonance effects, which implies that attack occurs at the hydrogen and not at R. Other evidence for the involvement of H in the rate-determining step is that there are large isotope effects.437 The nature of R′ also has an effect on the rate. In the reaction between triphenylmethane and R′Li, the rate decreased in the order R′ = allyl > Bu > Ph > vinyl > Me, although this order changed with changing concentration of R′Li, because of varying degrees of aggregation of the R′Li.438 With respect to the reagent, this reaction is a special case of Reaction 12-24.

Enantioselective reactions are known. The preparation of chlorodeuteriomethylithium proceeds with inversion from the corresponding enantiopure stannyl derivative.439 Although highly reactive chemically, it is configurationally stable at temperatures up to −78 °C. Enantioselective catalytic deprotonation with chiral ligands has been used for the deprotonation of N-Boc amines to give chiral α-trimethylsilyl derivatives.440 A barrier to enantiomerization has been observed for unstablized, chelated, and dipole-stabilized organolithium compounds. Studies of lithiopyrrolidines show free energies for enantiomerization in the range of 19–22 kcal mol−1 (79.5–92.1 kJ mol−1) at 0 °C.441

A closely related reaction is formation of nitrogen ylids442 from quaternary ammonium salts (see Reaction 17-8):

Phosphonium salts undergo a similar reaction (see Reaction 16-44).

OS II, 198; III, 413, 757; IV, 792; V, 751; VI, 436, 478, 737, 979; VII, 172, 334, 456, 524; VIII, 19, 391, 396, 606.

12-23 Metalation with Metals and Strong Bases

Metalation or Metalo-de-hydrogenation

![]()

Organic compounds can be metalated at suitably acidic positions by active metals and by strong bases.443 The reaction has been used to study the acidities of very weak acids (see Sec. 5.B.i). The conversion of terminal alkynes to acetylide ions is one important application.444 A gold-catalyst conversion of trimethylsilyl substituted esters and carbonates to the corresponding enolate anion has been reported445. Synthetically, an important use of the method is to convert aldehydes and ketones,446 carboxylic esters, and similar compounds to their enolate forms,447 for example, for use in nucleophilic substitutions (Reactions 10-67, 10-68, and 13-14) and in additions to multiple bonds (Reactions 15-24 and 16-53). Note that the reaction of carbonyl compounds with lithium dialkylamides leads to the corresponding enolate anion. This reaction was discussed in Reaction 10-68, in connection with the alkylation reaction of enolate anions.

OS I, 70, 161, 490; IV, 473; VI, 468, 542, 611, 683, 709; VII, 229, 339. Conversions of ketones or esters to enolates are not listed.

12.C.ii. Metals as Leaving Groups

A. Hydrogen as the Electrophile

12-24 Replacement of Metals by Hydrogen

Hydro-de-metalation or Demetalation

![]()

Organometallic compounds, including enolate anions, react with acids in reactions that replace the metal with hydrogen.448 The R group may be aryl (see Reaction 11-41). The reaction is often used to introduce deuterium or tritium into susceptible positions. For Grignard reagents, water is usually a strong enough acid, but stronger acids are also used. An important method for the reduction of alkyl halides consists of the process RX → RMgX → RH.

The organometallic compounds that are hydrolyzed by water are the ones high in the electromotive series: Na, K, Li, Zn, and so on. Enantioselective protonation of lithium enolates449 and cyclopropyllithium compounds450 have been reported. When the metal is less active, stronger acids are required. For example, R2Zn compounds react explosively with water, R2Cd slowly, and R2Hg not at all, although the latter can be cleaved with concentrated HCl. However, this general statement has many exceptions, some hard to explain. For example, BR3 compounds are completely inert to water, and GaR3 at room temperature cleave just one R group, but AlR3 reacts violently with water. However, BR3 can be converted to RH with carboxylic acids.451 For less active metals, it is often possible to cleave just one R group from a multivalent metal. For example,

![]()

Organometallic compounds of less active metals and metalloids (e.g., Si,452 Sb, and Bi), are quite inert to water. Organomercury compounds (RHgX or R2Hg) can be reduced to RH by H2, NaBH4, or other reducing agents.453 The reduction with NaBH4 takes place by a free radical mechanism.454 Alkyl-Si bonds are cleaved by H2SO4 [e.g., HOOCCH2CH2SiMe3 → 2CH2 + (HOOCCH2CH2SiMe3)2O].455

When the hydrogen of the HA is attached to carbon, this reaction is the same as 12-22.

This section does not list the many hydrolyses of Na or K enolates, and so on found in Organic Syntheses. The hydrolysis of a Grignard reagent to give an alkane is found at OS II, 478; the reduction of a vinylic tin compound at OS VIII, 381; and the reduction of an alkynylsilane at OS VIII, 281.

B. Oxygen Electrophiles

12-25 The Reaction between Organometallic Reagents and Oxygen456

Hydroperoxy-de-metalation; Hydroxy-de-metalation

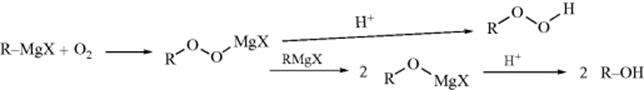

Oxygen reacts with Grignard reagents to give either hydroperoxides457 or alcohols. The reaction can be used to convert alkyl halides to alcohols without side reactions. With aryl Grignard reagents, yields are lower and only phenols are obtained, not hydroperoxides. Because of this reaction, oxygen should be excluded when Grignard reagents are prepared and used in various reactions.

Most other organometallic compounds also react with oxygen. Trialkylboranes and alkyldichloroboranes (RBCl2) can be conveniently converted to hydroperoxides by treatment with oxygen followed by hydrolysis.458 Dilithiated carboxylic acids (see Reaction 10-70) react with oxygen to give (after hydrolysis) α-hydroxy carboxylic acids.459 There is evidence that the reaction between Grignard reagents and oxygen involves a free radical mechanism.460

OS V, 918. See also, OS VIII, 315.

12-26 Reaction between Organometallic Reagents and Peroxides

tert-Butoxy-de-metalation

![]()

A convenient method of preparation of tert-butyl ethers consists of treating Grignard reagents with tert-butyl acyl peroxides.461 Both alkyl and aryl Grignard reagents can be used. The application of this reaction to Grignard reagents prepared from cyclopropyl halides permits cyclopropyl halides to be converted to tert-butyl ethers of cyclopropanols,462 which can then be easily hydrolyzed to the cyclopropanols. The direct conversion of cyclopropyl halides to cyclopropanols by Reaction 10-1 is not generally feasible, because cyclopropyl halides do not generally undergo nucleophilic substitutions without ring opening.

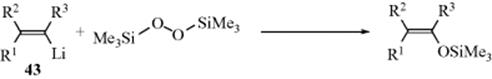

Vinyllithium reagents (43) react with silyl peroxides to give high yields of silyl enol ethers with retention of configuration.463 Since the preparation of 43 from vinylic halides (Reaction 12-39) also proceeds with retention, the overall procedure is a method for the stereospecific conversion of a vinylic halide to a silyl enol ether. Dialky ethers have been prepared from organotrifluoroborates and acetals464.

OS V, 642, 924.

12-27 Oxidation of Trialkylboranes to Borates

![]()

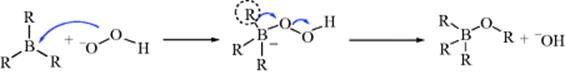

The reaction of alkenes with borane, monoalkyl, and dialkylboranes leads to a new organoborane (see Reaction 15-16). Treatment of organoboranes with alkaline H2O2 oxidizes trialkylboranes to esters of boric acid.465 This reaction does not affect double or triple bonds, aldehydes, ketones, halides, or nitriles that may be present elsewhere in the molecule. There is no rearrangement of the R group itself, and this reaction is a step in the hydroboration method of converting alkenes to alcohols (Reaction 15-16). The mechanism has been formulated as involving initial formation of an ate complex when the hydroperoxide anion attacks the electrophilic boron atom. Subsequent rearrangement from boron to oxygen,465 as shown, leads to the B–O–R unit.

Similar migration of the other two R groups and hydrolysis of the B–O bonds leads to the alcohol and boric acid. Retention of configuration is observed in R. Boranes can also be oxidized to borates in good yields with oxygen,466with sodium perborate (NaBO3)467 and with trimethylamine oxide, either anhydrous468 or in the form of the dihydrate.469 The reaction with oxygen is free radical in nature.470

OS V, 918; VI, 719, 852, 919.

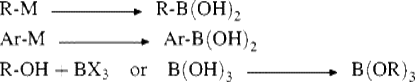

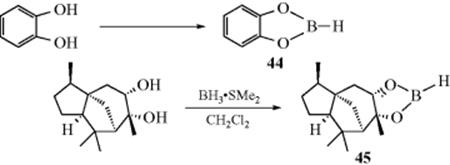

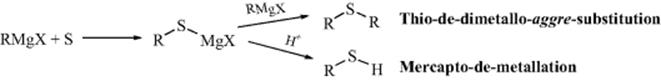

12-28 Preparation of Borates and Boronic Acids

Alkylboronic and arylboronic acids [RB(OH)2, and ArB(OH)2], respectively, are increasingly important in organic chemistry. The Pd catalyzed coupling reaction of aryl halides and aryl triflates with arylboronic acids (the Suzuki–Miyaura reaction, 13-12) is probably the most notable example. A simple synthesis involves the reaction of a Grignard reagent (e.g., phenylmagnesium bromide) with an alkyl borate to give phenylboronic acid.471 Alkylboronic acids are similarly prepared.472 Note that boronic acids are subject to cyclic trimerization with loss of water to form boroxines. Tetrahydroxydiboron has been used to prepare allylboronic acids, as well as potassium trifluoro(allyl)borates.473