March's Advanced Organic Chemistry: Reactions, Mechanisms, and Structure, 7th Edition (2013)

Part II. Introduction

Chapter 19. Oxidations and Reductions

19.B. Reactions

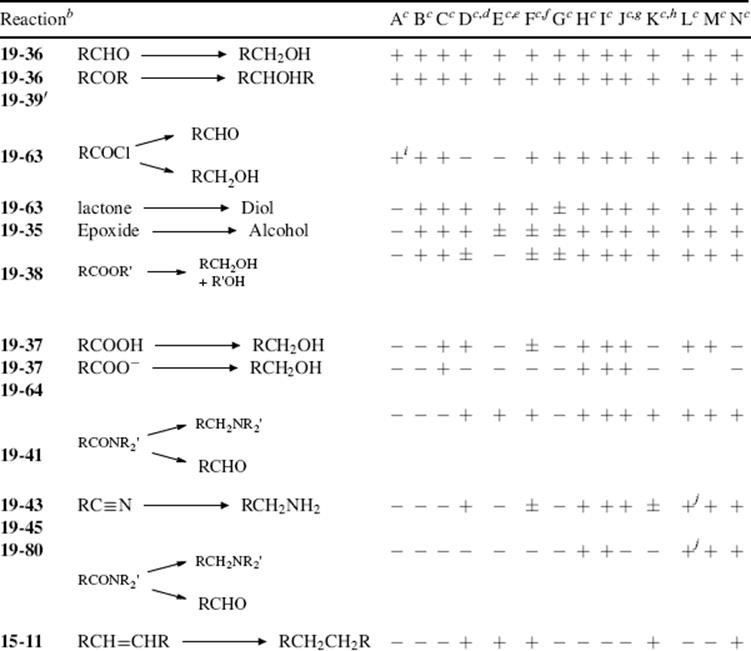

In this chapter, the reactions are classified by the type of bond change occurring to the organic substrate, in conformity with other chapters.9 This means that there is no discussion in any one place of the use of a particular oxidizing or reducing agent (e.g., acid dichromate or LiAlH4; except for a discussion of selectivity of reducing agents Sec. 19.B.ii, A). Some oxidizing or reducing agents are fairly specific in their action, attacking only one or a few types of substrate. Others, like acid dichromate, permanganate, LiAlH4, and catalytic hydrogenation, are much more versatile.10,11

19.B.i. Oxidations11

In some cases, oxidations have been placed in another chapter. The oxidations of an alkene to a diol (Reaction 15-48), and an aromatic compound to a diol (Reaction 15-49), or oxidations to an epoxide (Reaction 15-50) are placed in Chapter 15, for consistency with the concept of addition to a π bond. Diamination of an alkene (Reaction 15-53) and formation of aziridines (Reaction 15-54) are in Chapter 15 for the same reason. Most other oxidations have been placed here. The reactions in this section are classified into groups depending on the type of bond change involved. These groups are Section (A) eliminations of hydrogen, Section (B) oxidations involving cleavage of carbon–carbon bonds, Section (C) reactions involving replacement of hydrogen by oxygen, Section (D) reactions in which oxygen is added to the substrate, and Section (E) oxidative coupling.

A. Eliminations of Hydrogen

19-1 Aromatization of Six-Membered Rings

Hexahydro-terelimination

![]()

Six-membered alicyclic rings can be aromatized in a number of ways.12 Aromatization is accomplished most easily if there are already one or two double bonds in the ring or if the ring is fused to an aromatic ring. The reaction can also be applied to heterocyclic five- and six-membered rings. Many groups may be present on the ring without interference, and even gem-dialkyl substitution does not always prevent the reaction: In such cases, one alkyl group often migrates or is eliminated, but more drastic conditions are usually required for this. In some cases, OH and COOH groups are lost from the ring. Cyclic ketones are converted to phenols. Seven-membered and larger rings are often isomerized to six-membered aromatic rings, although this is not the case for partially hydrogenated azulene systems, which are frequently found in nature; these are converted to azulenes.

There are three types of reagents most frequently used to effect aromatization.

1. Hydrogenation catalysts13 (e.g., Pt, Pd,14 and Ni). Palladium trifluoroacetate also facilitates oxidative aromatization of cyclohexene.15 In this case, the reaction is the reverse of double-bond hydrogenation (15-11 and 15-15), and presumably the mechanism is also the reverse, although not much is known.16 Cyclohexene has been detected as an intermediate in the conversion of cyclohexane to benzene, using Pt.17 The substrate is heated with the catalyst at ~300–350 °C. The reactions can often be carried out under milder conditions if a hydrogen acceptor (e.g., maleic acid, cyclohexene, or benzene) is present to remove hydrogen as it is formed. The acceptor is reduced to the saturated compound. Other transition metals can be used.18 It has been reported that dehydrogenation of 1-methylcyclohexene-1-13C over an alumina catalyst gave toluene with the label partially scrambled throughout the aromatic ring.19 For polycyclic systems, heating with oxygen on activated carbon generates the aromatic compound, as in the conversion of dihydroanthracene to anthracene.20

2. The elements sulfur and selenium, which combine with the hydrogen evolved to give, respectively, H2S and H2Se. Little is known about this mechanism either.21

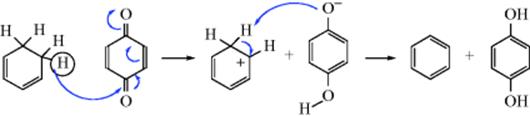

3. Quinones22 become reduced to the corresponding hydroquinones. Two important quinones often used for aromatizations are chloranil (2,3,5,6-tetrachloro-1,4-benzoquinone) and DDQ (2,3-dichloro-5,6-dicyano-1,4-benzoquinone).23 The latter is more reactive and can be used in cases where the substrate is difficult to dehydrogenate. It is likely that the mechanism involves a transfer of hydride to the quinone oxygen, followed by the transfer of a proton to the phenolate ion.24

Other reagents25 have been used for aromatization of six-membered rings, including atmospheric oxygen, MnO2,26 SeO2, H2SO4, and a Ru catalyst.27 The last-mentioned reagent also dehydrogenates cyclopentanes to cyclopentadienes. In some instances, the hydrogen is not released as H2 or transferred to an external oxidizing agent, but instead serves to reduce another molecule of substrate. This is a disproportionation reaction and can be illustrated by the conversion of cyclohexene to cyclohexane and benzene.

Heteroatom rings, as found in quinoline derivatives, for example, can be generated from amino-ketones with [hydroxy(tosyloxy)iodo]benzene and perchloric acid28 or with NaHSO4–Na2Cr2O7 on wet silica.29Dihydropyridines are converted to pyridines with NaNO2–oxalic acid and wet silica,30 BaMnO4,31 FeCl3–acetic acid,32 or SeO2.33Hantzsch 1,4-dihydropyridines (see Reactions 15-14 and 16-17) are aromatized by treatment with ferric perchlorate in acetic acid.34 Cyclic imines are converted to pyridine derivatives with NCS and then excess sodium methoxide.35 Enamines are aromatized with Sn or Sb compounds.36

Note that hydrogenolysis of cyclohexane leads to n-hexane with hydrogen and an Ir catalyst.37

OS II, 214, 423; III, 310, 358, 729, 807; IV, 536; VI, 731. Also see, OS III, 329.

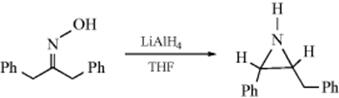

19-2 Dehydrogenations Yielding Carbon–Carbon Double Bonds

Dihydro-elimination

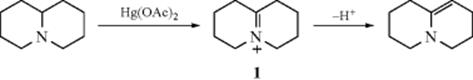

Dehydrogenation of an aliphatic compound to give a double bond in a specific location is not usually a feasible process, although industrially mixtures of alkenes are obtained in this way from mixtures of alkanes (generally by heating with chromia–alumina catalysts). There are, however, some notable exceptions. Heating cyclooctane with an Ir catalyst leads to cyclooctene.38 Treating alkenes that have an allylic hydrogen with CrCl2 converts them to allenes.39 It is not surprising, however, that most of the exceptions generally involve cases where the new double bond can be in conjugation with a double bond or with an unshared pair of electrons already present.40 One example is the synthesis developed by Leonard and Musker,41 in which tertiary amines give enamines (Reaction 10-69) when treated with mercuric acetate42 (see the example above). In this case, the initial product is the iminium ion (1) that loses a proton to give the enamine. Other transition metal catalysts convert amines to enamines, including Co compounds.43Hünig's base (diisopropylethylamine) was converted to the enamine N,N-diisopropyl-N-vinylamine by heating with an Ir catalyst.44

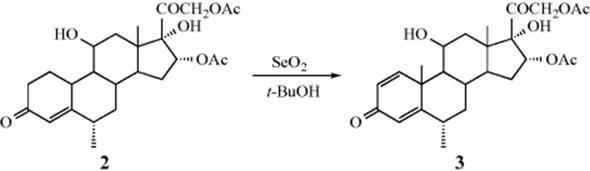

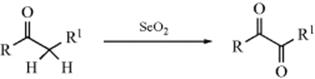

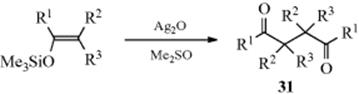

The oxidizing agent SeO2 can in certain cases convert a carbonyl compound to an α,β-unsaturated carbonyl compound by removing H245 (note that this reagent more often gives Reaction 19-17). This reaction has been most often applied in the steroid series, an example being formation of 2 from 3.46 Similarly, SeO2 has been used to dehydrogenate 1,4-diketones47 and 1,2-diarylalkanes. These conversions can also be carried out by certain quinones, most notably DDQ (see Reaction 19-1).24 Molecular oxygen has been used to convert cyclic ketones to the conjugated ketone in the presence of a Pd catalyst.48

Simple aldehydes and ketones have been dehydrogenated (e.g., cyclopentanone → cyclopentenone) by PdCl2,49 by FeCl3,50 and by benzeneseleninic anhydride51 (this reagent also dehydrogenates lactones in a similar manner), among other reagents. In an indirect method of achieving this conversion, the silyl enol ether of a simple ketone is treated with DDQ52 or with triphenylmethyl cation53 (for another indirect method, see Reaction 17-12). Silyl enol ethers give the conjugated ketone upon treatment with ceric ammonium nitrate in DMF54 or with Pd(OAc)2/NaOAc/O2.55

Simple linear alkanes have been converted to alkenes by treatment with certain transition metal compounds.56

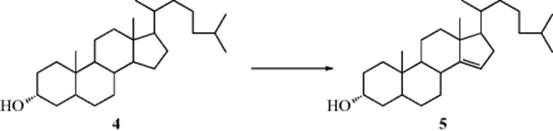

An entirely different approach (remote functionalization) allows specific dehydrogenation, as reported by R. Breslow57 and by J.E. Baldwin et al.58 3α-Cholestanol (4) was converted to 5α-cholest-14-en-3α-ol (5), for example, thus introducing a double bond at a specific site remote from any functional group.59

Certain 1,2-diarylalkenes (ArCH=CHAr′) have been converted to the corresponding alkynes (ArC![]() CAr′) by treatment with t-BuOK in DMF.60 Dihydroindoles are converted to indoles with N,N′,N″-trichloro-1,3,5-triazin-2,4,6-trione and DBU.61

CAr′) by treatment with t-BuOK in DMF.60 Dihydroindoles are converted to indoles with N,N′,N″-trichloro-1,3,5-triazin-2,4,6-trione and DBU.61

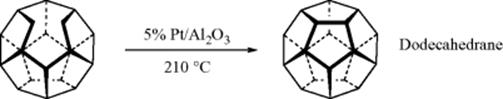

A different kind of dehydrogenation was used in the final step of Paquette's synthesis of dodecahedrane62:

OS V, 428, VII, 4, 473.

19-3 Oxidation or Dehydrogenation of Alcohols to Aldehydes and Ketones

C,O-Dihydro-elimination

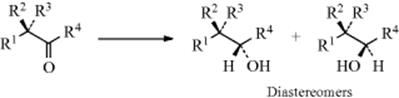

![]()

Primary alcohols can be converted to aldehydes and secondary alcohols to ketones in seven main ways:63

1. With Chromium Reagents.64 Secondary alcohols are easily oxidized to ketones by dichromate in acidic media65 at room temperature or slightly above. A solution of chromic and sulfuric acid in water is known as the Jones reagent.66 Secondary alcohols are oxidized to ketones rapidly and in high yield without disturbing any double or triple bonds that may be present (see Reaction 19-10) and without epimerizing an adjacent stereogenic center.67Mixing sodium dichromate with an alcohol, without solvent, provides a method for oxidation when the mixture is shaken.68 Chromium trioxide (CrO3)69 has been used to oxidize primary and alcohols under solvent-free conditions. Chromium trioxide on silica gel, in supercritical CO2, oxidizes alcohols to the corresponding carbonyl.70 For acid-sensitive compounds, trimethylsilyl chromates71 can be used. Chromium trioxide with aq tert-butylhydroperoxide oxidizes benzylic alcohols with microwave irradiation.72 Phase-transfer catalysis is particularly useful,73 especially when the substrates are generally insoluble in water (see Sec. 10.G.v). A catalytic amount of Cr(acac)3 in conjunction with H5IO5 oxidizes benzylic alcohols to aldehydes.74

The Jones reagent can also oxidize primary allylic alcohols to the corresponding aldehydes,75 although overoxidation to the carboxylic acid is a problem.76 Oxidative cleavage of primary alcohols has been observed in the presence of molecular sieves 3 Å.77 One way to mitigate overoxidation is to distil the aldehyde as it is formed, but this is not always possible. Due to these problems, other oxidizing conditions have been used to convert at least some primary alcohols to aldehydes.78 Perhaps the three most commonly used Cr(VI) reagents used for the oxidation of allylic alcohols include79 dipyridine Cr(VI) oxide (Collins' reagent),80 pyridinium chlorochromate (PCC),81 and pyridinium dichromate (PDC).82 The PCC is somewhat acidic, and acid-catalyzed rearrangements have been observed.83

Analogous to the use of pyridine for PCC and PDC, a variety of amines and diamines have been converted to tetraalkylammonium halochromates or dichromates, including N-benzyl 1,4-diazabicyclo[2.2.2]octane ammonium dichromate with microwave irradiation,84 γ-picolinium chlorochromate,85 and quinolinium fluorochromate.86 Benzyltriphenylphosphonium chlorochromate has been used in a similar manner.87 Oxidizing agents have been supported on a polymer,88 including chromic acid,89 as well as poly[vinyl(pyridinium fluorochromate)].90 Triphenylmethylphosphonium dichromate is effective for selective oxidation of benzylic alcohols.91

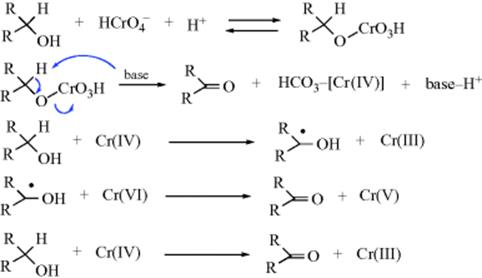

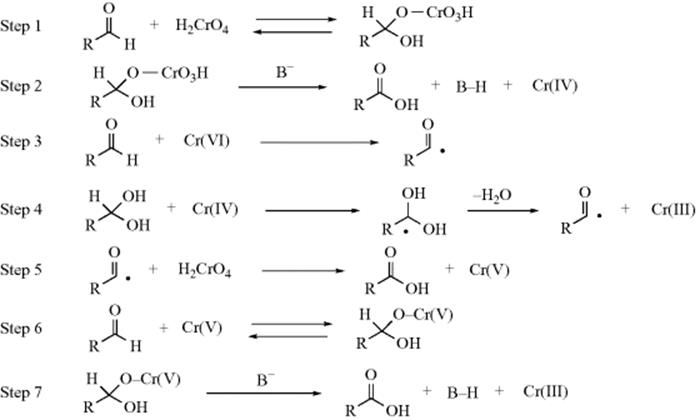

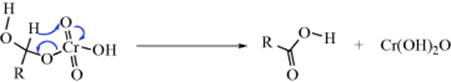

Studies on the mechanism of oxidation with acid dichromate92 led to the currently accepted mechanism as proposed by Westheimer93 (cf. the first two steps with Sec. 19.A, category 4).

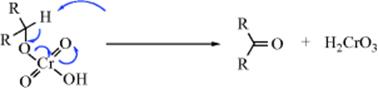

The base in the second step may be water, although it is also possible94 that in some cases no external base is involved and that the proton is transferred directly to one of the CrO3H oxygen atoms in which case the Cr(IV) species produced would be H2CrO3. Part of the evidence for this mechanism was the isotope effect of ~6 found on use of MeCDOHMe, showing that the α hydrogen is removed in the rate-determining step.95 Note that, as in Reaction 19-23 the substrate is oxidized by three different oxidation states of chromium.96

With other oxidizing agents discussed below, mechanisms are less clear.97 It seems certain that some oxidizing agents operate by a hydride-shift mechanism,98 for example, dehydrogenation with triphenylmethyl cation99 and the Oppenauer oxidation, and some by a free radical mechanism (e.g., oxidation with S3O82−100 and with VO2+101). A summary of many proposed mechanisms is given by Littler.102

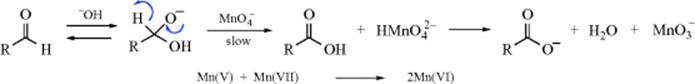

2. With Manganese and Other Metal Oxidizing Agents. Potassium permanganate (KMnO4) has been used for the oxidation of alcohols.103 Benzylic and allylic alcohols have been selectively oxidized to the aldehydes in the presence of saturated alcohols by the use of potassium permanganate (KMnO4) under phase-transfer conditions.104 Phase-transfer catalysis has also been used with chromic acid,105 and ruthenium tetroxide.106 Ultrasound has been used for KMnO4 oxidations.107 Permanganate supported on a polymer has been used.108

Permanganate109 is an important reagent for the selective oxidation of benzylic alcohols primary and benzylic alcohols, in preference to aliphatic substrates. 110A variation oxidizes alcohols with MnO2/AlCl3.111

An alternative to MnO2 is the oxidation of allylic and benzylic alcohols with Me3NO in the presence of CHDFe(CO)3.112 Similar oxidation occurs with NaBrO3 in aq MeCN113 or K2FeO4 on clay.114 The reaction of AuCl with an anionic ligand leads to oxidation of primary alcohols to aldehydes.115 The Grubbs' catalyst, PhCH=Ru(PCy3)2Cl2, where Cy = cyclohetyl, (see 156 in Reaction 18-37), in the presence of KOH, oxidized alcohols.116

Tetrapropylammonium perruthenate (Pr4N+ RuO4−; also called TPAP; the Ley reagent)117 is an important oxidizing agent that is compatible with the presence of other functionality in the molecule.118 In the presence of molecular oxygen, oxidation of alcohols is catalytic in TPAP.119 This reagent has been bound to a polymer.120 Methods have been developed for recovery of the catalyst and reuse of TPAP.121

Many other oxidizing agents have been employed. Examples include ruthenium tetroxide,122 MeReO3,123 HNO3 with a Yb(OTf)3 catalyst,124 FeBr3–H2O2,125 ceric ammonium nitrate in an ionic liquid,126 a Bi catalyst,127 O2with transition metal catalysts,128 and with RuO2 and a zeolite catalyst.129 Microwave induced oxidation of benzylic alcohols was reported using zeolite-supported ferric nitrate.130

Reagents that can be used specifically to oxidize a secondary OH group in the presence of a primary OH group131 are H2O2–ammonium molybdate,132 or urea–H2O2 with MgBr2,133 while RuCl2(PPh3)3–benzene,134 osmium tetroxide,135 and Br2–Ni(OBz)2136 all oxidize primary OH groups in the presence of a secondary OH group.137 Certain zirconocene complexes can selectively oxidize only one OH group of a diol, even if both are primary.138 α-Hydroxy ketones are oxidized to 1,2-diketones with Bi(NO3)3 and a Cu(OAc)2 catalyst,139 ferric chloride (solid state),140 or O2 and a V catalyst.141 1,2-Diols are oxidized to chiral α-hydroxy-ketones using NBS with a chiral Cu catalyst.142

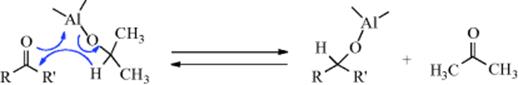

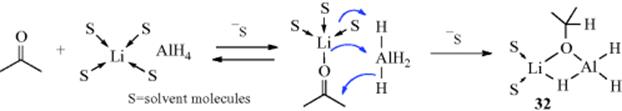

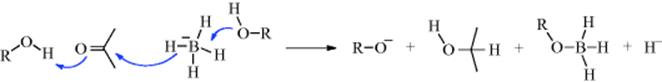

3. The Oppenauer Oxidation. When a ketone in the presence of an aluminum alkoxide is used as the oxidizing agent (it is reduced to a secondary alcohol), the reaction is known as the Oppenauer oxidation.143 This is the reverse of the Meerwein–Ponndorf–Verley reaction (19-36) and the mechanism is also the reverse. The ketones most commonly used are acetone, butanone, and cyclohexanone. A common base is aluminum tert-butoxide. The chief advantage of the method is its high selectivity. Although the method is most often used for the preparation of ketones, it has also been used for aldehydes. An Ir catalyst144 has been developed for the Oppenauer oxidation, and also a water-soluble Ir catalyst.145 Homogeneous water-soluble complexes catalyze the reaction.146 An uncatalyzed reaction under supercritical conditions was reported.147

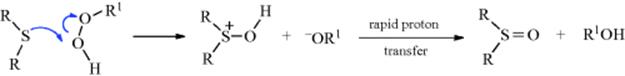

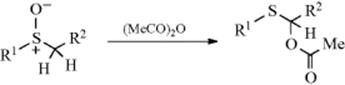

4. DMSO Based Reagents. The use of oxalyl chloride and DMSO at low temperature is called the Swern oxidation148 and is widely used. A sulfonium salt is produced in situ, which reacts with the alcohol to generate the key intermediate required for oxidation.149 Maintaining the low-reaction temperature is essential in this reaction, however, since the reagent generated in situ decomposes at temperatures significantly below ambient. Note that Swern oxidation of molecules having alcohol moieties, as well as a disulfide, leads to the ketone without oxidation of the sulfur.150 Sulfoxides other than DMSO can be used in conjunction with oxalyl chloride for the oxidation of alcohols,151 including fluorinated sulfoxides152 and a polymer-bound sulfoxide.153

Similar oxidation of alcohols has been carried out with DMSO and other reagents154 in place of DCC: acetic anhydride,155 SO3–pyridine–triethylamine,156 trifluoroacetic anhydride,157 pivaloyl chloride,158 tosyl chloride,159Ph3P+Br−,160 trimethylamine N-oxide,161 a Mo catalyst and O2,162 and methanesulfonic anhydride.517 Dimethyl sulfoxide in 48% HBr oxidizes benzylic alcohols to aryl aldehydes.163 An alcohol is treated with DMSO, DCC,164and anhydrous phosphoric acid165 in what is called Moffatt oxidation. In this way, a primary alcohol can be converted to the aldehyde with no carboxylic acid being produced. The strong acid conditions are sometimes a problem, and complete removal of the dicyclohexylurea byproduct can be difficult.

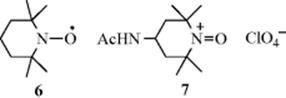

5. TEMPO and Related Reagents. The nitroxyl radical TEMPO (6) has been used in conjunction with coreagents, including mcpba,166 O2 with transition metal catalysts,167 O2 with HBr and tert-butylnitrite,168 CuBr2(bpy)–air (bpy = 2,2′-bipyridyl),169 CuBr·SMe2 in perfluorous solvents,170 bromohydantoins,171 enzymes,172 carbenes,173 NaNO2–HCl,174 NaIO4,175 and H5IO6.176 Silica-supported TEMPO,177 polymer-bound TEMPO,178 and PEG–TEMPO179 have been used. The TEMPO derived ionic liquids,180 or ionic liquid-supported TEMPO181 have been used for the oxidation of alcohols. The TEMPO compound has also been used with a polymer-bound hypervalent iodine reagent.182 A catalytic reaction using 5% TEMPO and 5% CuCl with O2 in an ionic liquid oxidizes benzylic alcohols to the corresponding aldehyde.183 Ion-supported TEMPO oxidation in water is possible.184

Other nitroxyl radical oxidizing agents are known.185 A related oxidizing agent is oxoammonium salt 7 (Bobbitt's reagent), a stable and nonhygroscopic salt that oxidizes primary and secondary alcohols in dichloromethane.186 The mechanism of oxidation for 7 has been examined.187

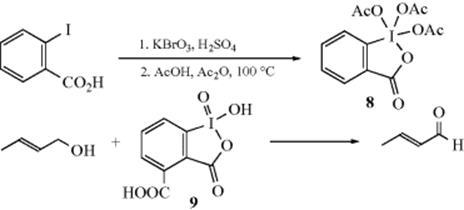

6. With Hypervalent Iodine Reagents.188 Treatment of 2-iodobenzoic acid with KBrO3 in H2SO4 and heating the resulting product to 100 °C with acetic anhydride and acetic acid189 gives hypervalent iodine reagent (8), the so-called Dess–Martin Periodinane.190 This reagent reacts with alcohols at ambient temperature to give the corresponding aldehyde or ketone.191 The reaction is accelerated by water192 and a water-soluble periodinane [o-iodoxybenzoic acid (9), IBX]193 has been prepared that oxidized allylic alcohols to conjugated aldehydes.194 2-Methyl-2-propanol has been used as a solvent.195 The reagent has an indefinite shelf-life in a sealed container, but hydrolysis occurs upon long-term exposure to atmospheric moisture. A note of CAUTION! The Dess–Martin reagent can be shock sensitive under some conditions and explode ~200 °C.196

Iodine has been used as a cocatalyst.197 Other hypervalent iodine oxidizing reagents are known,198 including PhI(OAc)2/TEMPO,199 PhI(OAc)2–chromium salen,200 PhI(OAc)2 supported on alumina with microwave irradiation,201 and an ion-supported hypervalent iodine(III) reagent.202 Microwave irradiation of benzylic alcohols with PhI(OH)OTs gave the corresponding aldehyde.203 Hypervalent iodine compounds have been used in ionic liquids.204 Heating benzylic alcohols with o-iodoxybenzoic acid under solvent-free conditions gave the aldehyde.205 2-Iodobenzenesulfonic acid is a very active catalyst for oxidation of alcohols using Oxone.206

7. By Catalytic Dehydrogenation. For the conversion of primary alcohols to aldehydes, dehydrogenation catalysts have the advantage over strong oxidizing agents that further oxidation to the carboxylic acid is prevented. Copper chromite is often used, but other catalysts (e.g., Ag and Cu), have also been employed. Many ketones were prepared in this manner. Catalytic dehydrogenation is more often used industrially than as a laboratory method. However, procedures using Cu(II) complexes,207 Rh complexes,208 Ru complexes,209 Raney nickel,210 and Pd complexes211 (under phase transfer conditions)212 have been reported. Allylic alcohols213 are oxidized to the corresponding saturated aldehyde or ketone by heating with a Rh catalyst, and benzylic alcohols are converted to the aldehyde with a Rh catalyst.214 Propargylic alcohols are oxidized by heating with a V catalyst.215 Secondary alcohols are oxidized with Bi(NO3)3 on Montmorillonite.216 Biooxidation is possible as well via hydrogen transfer.217

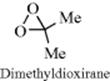

8. Miscellaneous Reagents.218 Nitric acid in dichloromethane oxidizes benzylic alcohols to the corresponding ketone.219 Bromine is an effective oxidant, and iodine under photochemical conditions has been used.220 Heating a 1,2-diol with NBS in CCl4 gave the 1,2-diketone.221 Iodine has been used in conjunction with DMSO and hydrazine.222 Enzymatic oxidations have been reported.223 Oxidation of alcohols in water is possible using I2O5.224Dimethyl dioxirane225 oxidizes benzylic alcohols to the corresponding aldehyde,226 and dioxirane reagents are sufficiently mild that an α,β-epoxy alcohol was oxidized to the corresponding ketone, without disturbing the epoxide, using methyl trifluoromethyl dioxirane.227 Hydrogen peroxide with urea oxidizes aryl aldehydes in formic acid.228tert-Butylhydroperoxide with a Cu catalyst gives oxidation in an ionic liquid.229 Potassium monoperoxysulfate in the presence of a chiral ketone oxidizes 1,2-diols to α-hydroxy ketones enantioselectively.230 Potassium monoperoxysulfate also oxidizes secondary alcohols in the presence of O2.231 Air, in the presence of a zeolite oxidizes benzylic alcohols.232 Periodic acid oxidizes aldehydes or ketones in the presence of a PCC catalyst.233 Sodium hypochlorite in acetic acid234 or in water with β-cyclodextrin235 is a useful oxidizing agent. Calcium hypochlorite on moist alumina with microwave irradiation has been used to oxidize benzylic alcohols.236 Hydrogen bromide in aq H2O2 oxidizes secondary alcohols to ketones.237 With ultrasound, DDQ selectively oxidizes a benzylic or allylic hydroxyl group of 1,2-diols with those substituents.238 Photoxidation of alcohols is possible in the presence of a catalytic amount of NBS.239 A mixture of I2–KI–K2CO3–H2O oxidizes alcohols to aldehydes or ketones under anaerobic conditions.240 Similarly KBrO3/ZrClO2·8H2O can be used to oxidize alcohols.241 Oxone oxidizes alcohols, catalyzed by AlCl3.242

Tetrabutylammonium periodate243 and benzyltriphenylphosphonium periodate.244 oxidizes primary alcohols to aldehydes. On the other hand, Fremy's salt (see Reaction 19-4) selectively oxidizes benzylic alcohols and not allylic or saturated ones.245

In a related reaction to the oxidation of alcohols, it is possible to oxidize ethers to aldehydes. Oxidation of trimethylsilyl ethers with O2, a catalytic amount of N-hydroxyphthalimide and a Co catalyst, give an aldehyde.246Microwave irradiation with BiCl2 oxidizes benzylic TMS ethers to the aldehyde.247 Microwave irradiation on zeolite supported ferric nitrate has been used.248O-Tetrahydropyranyl ethers (O-THP) have been oxidized to the aldehyde with ferric nitrate on zeolites,249 and the Pd catalyzed oxidation of allylic esters to conjugated ketones is known.250N-Bromosuccinimide with β-cyclodextrin oxidizes tetrahydropyranyl ethers in water.251

OS I, 87, 211, 241, 340; II, 139, 541; III, 37, 207; IV, 189, 192, 195, 467, 813, 838; V, 242, 310, 324, 692, 852, 866; VI, 218, 220, 373, 644, 1033; VII, 102, 112, 114, 177, 258, 297; VIII, 43, 367, 386; IX, 132, 432. Also see, OS IV, 283; VIII, 363, 501.

19-4 Oxidation of Phenols and Aromatic Amines to Quinones

1/O,6/O-Dihydro-elimination

![]()

Ortho and para diols are easily oxidized to o- and p-quinones, respectively.252 Either or both OH groups can be replaced by NH2 groups to give the same products, although for the preparation of o-quinones only OH groups are normally satisfactory. The reaction has been successfully carried out with other groups para to OH or NH2; halogen, OR, Me, t-Bu, and even H, although yields are poor with the latter. Many oxidizing agents have been used: acid dichromate,253 silver oxide, silver carbonate, lead tetraacetate, HIO4, NBS–H2O–H2SO4,254 dimethyl dioxirane,255 and atmospheric oxygen.256 Oxidation has been done photochemically with O2 and tetraphenylporphine.257 A particularly effective reagent for rings with only one OH or NH2 group is (KSO3)2N–O· (dipotassium nitrosodisulfonate; Fremy's salt), which is a stable free radical.258 A mixture of 4-iodophenoxyacetic acid and Oxone is an effective catalyst for the oxidation of p-alkoxyphenols to p-quinones.259 A supported iron phthalocyanine facilitates the aromatic oxidation of phenols.260

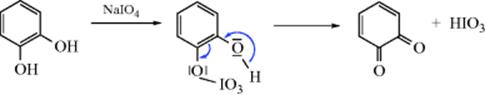

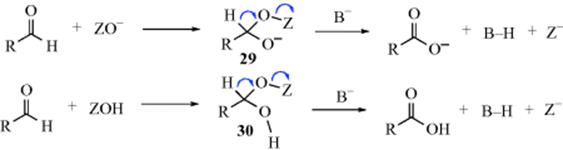

Less is known about the mechanism than is the case for oxidizing simple alcohols in Reaction 19-3, and it seems to vary with the oxidizing agent. For oxidation of catechol with NaIO4, it was found that the reaction conducted in H218O gave unlabeled quinone.261 Therefore the following mechanism262 was proposed:

When catechol was oxidized with MnO4− under aprotic conditions, a semiquinone radical ion intermediate was involved.263 For autoxidations264 (i.e., with atmospheric O2) a free radical mechanism is known to operate.265

OS I, 383, 482, 511; II, 175, 254, 430, 553; III, 663, 753; IV, 148; VI, 412, 480, 1010.

19-5 Dehydrogenation of Amines to Nitriles or Imines

1/1/N,2/2/C-Tetrahydro-bielimination

![]()

Primary amines at a primary carbon can be dehydrogenated to nitriles. The reaction has been carried out with a variety of reagents, among others, I2 in aq NH3,266 IBX see 19-3, category 6),267 NaOCl,268 Me3N–O/OsO4,269Ru/Al2O3/O2,270 and CuCl/O2/pyridine.271 Iodine and 1,3-diiodo-5,5-dimethylhydantoin in aq ammonia converted both amines and alcohols to nitriles.272 Dehydrogenation of amines has been done in aq micelles.273

Several methods have been reported for the dehydrogenation of secondary amines to imines.274 Among them275 are treatment with (1) iodosylbenzene (PhIO) alone or in the presence of a Ru complex,276 (2) DMSO and oxalyl chloride,277 and (3) t-BuOOH and a Rh catalyst.278N-Tosyl aziridines are converted to N-tosyl imines when heated with a Pd catalyst.279 An interesting variation treats pyrrolidine with iodobenzene and a Rh catalyst to give 2-phenylpyrroline.280

A reaction that involves dehydrogenation to an imine that then reacts further is the reaction of primary or secondary amines281 with Pd black.282 The imine initially formed by the dehydrogenation reacts with another molecule of the same or a different amine to give an aminal, which loses NH3 or RNH2 to give a secondary or tertiary amine. An example is the reaction between N-methylbenzylamine and butylmethylamine, which produces 95% N-methyl-N-butylbenzylamine.

In a related reaction, alkyl azides react with BrF3 to give the corresponding nitrile.283

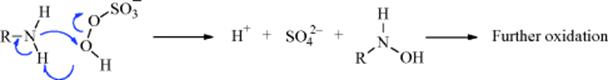

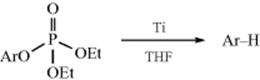

19-6 Oxidation of Hydrazines, Hydrazones, and Hydroxylamines

1/N,2/N-Dihydro-elimination

![]()

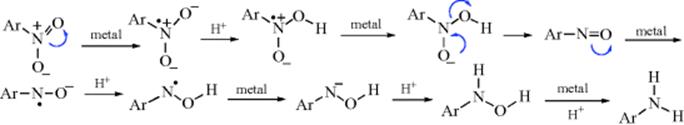

N,N′-Diarylhydrazines (hydrazo compounds) are oxidized to azo compounds by several oxidizing agents, including NaOBr, K3Fe(CN)6 under phase-transfer conditions284 FeCl3,285 MnO2 (this reagent yields cis azobenzenes),286CuCl2, and air and NaOH.287 The reaction is also applicable to N,N′-dialkyl- and N,N′-diacylhydrazines. Hydrazines (both alkyl and aryl) substituted on only one side also give azo compounds,288 but these are unstable and decompose to nitrogen and the hydrocarbon:

![]()

Aniline derivatives are converted to azo compounds by heating with cetyltrimethylammonium dichromate in chloroform.289 When hydrazones are oxidized with HgO, Ag2O, MnO2, PbO4, or certain other oxidizing agents, diazo compounds (R2C=N–NH2 → R2C=N+=N−) are obtained290:

Hydrazones of the form ArCH=NNH2 react with HgO in solvents, (e.g., diglyme or ethanol) to give nitriles (ArCN).291 It is possible to oxidize dimethylhydrazones (R–C=N–NMe2) to the corresponding nitrile (R–C![]() N) with magnesium monoperoxyphthalate (MMPP),292 or with dimethyl dioxirane.293 Oxone on wet alumina also converts hydrazones to nitriles with microwave irradiation.294 Oximes of aromatic aldehydes are converted to aryl nitriles with InCl3295 (ketoximes give a Beckmann rearrangement, Reaction 18-17).

N) with magnesium monoperoxyphthalate (MMPP),292 or with dimethyl dioxirane.293 Oxone on wet alumina also converts hydrazones to nitriles with microwave irradiation.294 Oximes of aromatic aldehydes are converted to aryl nitriles with InCl3295 (ketoximes give a Beckmann rearrangement, Reaction 18-17).

In a related reaction, primary aromatic amines have been oxidized to azo compounds by a variety of oxidizing agents, among them MnO2, lead tetraacetate, O2 and a base, BaMnO4,296 and sodium perborate in acetic acid. tert-Butyl hydroperoxide has been used to oxidize certain primary amines to azoxy compounds.297

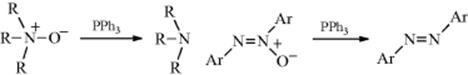

Nitrones [C=N+(R)–O−] are generated by the oxidation of N-hydroxyl secondary amines with 5% aq NaOCl.298 Secondary amines (e.g., dibenzylamine) can be converted to the corresponding nitrone by heating with cumyl hydroperoxide in the presence of a titanium catalyst.299

OS II, 496; III, 351, 356, 375, 668; IV, 66, 411; V, 96, 160, 897; VI, 78, 161, 334, 392, 803, 936; VII, 56. Also see, OS V, 258. For oxidation of primary amines, see OS V, 341.

B. Oxidations Involving Cleavage of Carbon–Carbon Bonds300

19-7 Oxidative Cleavage of Glycols and Related Compounds

2/O-De-hydrogen-uncoupling

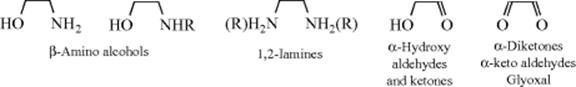

![]()

1,2-Diols (glycols) are easily cleaved under mild conditions and in good yield with periodic acid or lead tetraacetate.301 The reaction generates 2 molar equivalents of aldehyde, or 2 molar equivalents of ketone, or 1 molar equivalent of each, depending on the groups attached to the two carbons. The yields are so good that alkenes are often converted to diols (Reaction 15-48), and then cleaved with HIO4 or Pb(OAc)4 rather than being cleaved directly with ozone (Reaction 19-9) or dichromate or permanganate (Reaction 19-10). The diol can be generated and cleaved in situ from an alkene to give the carbonyl compounds.302 A number of other oxidizing agents also give the same products, among them303 aq sodium hypochlorite (NaOCl),304 activated MnO2,305 O2 and a Ru catalyst,306 or PCC.307 Permanganate, dichromate, and several other oxidizing agents308 also cleave glycols, giving carboxylic acids rather than aldehydes, but these reagents are seldom used synthetically.

The two reagents (periodic acid and lead tetraacetate) are complementary, since periodic acid is best used in water and lead tetraacetate in organic solvents. Chiral lead carboxylates have been prepared for the oxidative cleavage of 1,2-diols.309 When three or more OH groups are located on adjacent carbons, the middle one (or ones) is converted to formic acid.

Other compounds that contain oxygen atoms or nitrogen atoms on adjacent carbons undergo similar cleavage:

Cyclic 1,2-diamines are cleaved to diketones with dimethyl dioxirane.310 α-Diketones and α-hydroxy ketones are also cleaved by alkaline H2O2.311 Periodic acid (HIO4) has been used to cleave epoxides to aldehydes,312 for example,

![]()

α-Hydroxy and α-keto acids are not cleaved by HIO4 but are cleaved by NaIO4 in methanol in the presence of a crown ether Pb(OAc)4,313 alkaline H2O2, and other reagents. These are oxidative decarboxylations. α-Hydroxy acids give aldehydes or ketones, and α-keto acids give carboxylic acids. Also see, Reaction 19-12 and 19-13.

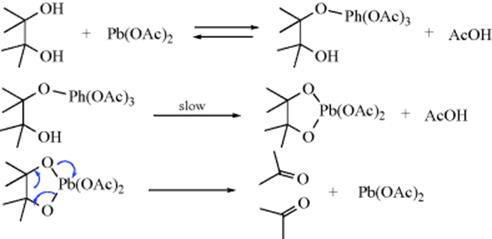

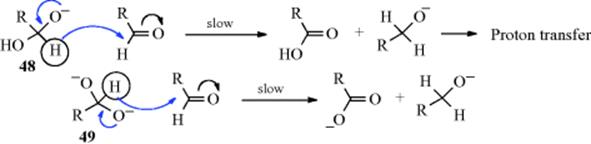

The mechanism of glycol oxidation with Pb(OAc)4 was proposed by Criegee et al.:314

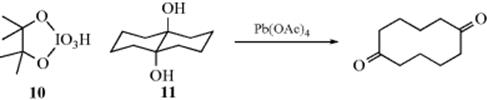

This mechanism is supported by (1) the kinetics are second order (first order in each reactant); (2) added acetic acid retards the reaction (drives the equilibrium to the left); and (3) cis-glycols react much more rapidly than transglycols.315 For periodic acid, the mechanism is similar, with the intermediate (10)316

However, the cyclic-intermediate mechanism cannot account for all glycol oxidations, since some glycols that cannot form such an ester (e.g., 11) are nevertheless cleaved by lead tetraacetate (although other glycols that cannot form cyclic esters are not cleaved, by either reagent317). To account for cases like 11, a cyclic transition state has been proposed:315

OS IV, 124; VII, 185; VIII, 396.

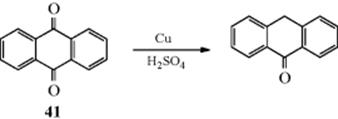

19-8 Oxidative Cleavage of Ketones, Aldehydes, and Alcohols

Cycloalkanone oxidative ring opening

![]()

Oxidative cleavage of open-chain ketones or alcohols318 is a preparative procedure that is seldom useful, not because these compounds do not undergo oxidation (they do, except for diaryl ketones), but because the result is generally a hopeless mixture. Aryl methyl ketones (e.g., acetophenone), however, are readily oxidized to aryl carboxylic acids with Re2O7 and 70% aq tert-butyl hydroperoxide.319 Oxygen with a mixture of Mn and Co catalysts give similar oxidative cleavage,320 as do hypervalent iodine compounds.321 Aldehydes, (e.g., PhCH2CHO) are cleaved to benzaldehyde with phosphonium dichromate in refluxing acetonitrile.322 1,3-Diketones (e.g., 1,3-diphenyl-1,3-propanedione) are oxidatively cleaved with aq Oxone to give benzoic acid.323 Cyclic α-chloro ketones are cleaved to give an α,ω-functionalized compound (acetal–ester) when treated with cerium (IV) sulfate tetrahydrate and O2.324

Despite problems with acyclic ketones, the reaction is useful for the conversion of cyclic ketones and the corresponding secondary alcohols to the dicarboxylic acid in good yield. The formation of adipic acid from cyclohexanone (shown above) is an important industrial procedure. Dichromate in acidic media and permanganate are the most common oxidizing agents, although autoxidation (oxidation with atmospheric oxygen) in alkaline solution325 and potassium superoxide under phase-transfer conditions326 have also been used. O-Silyl-ketones have been cleaved to esters using electrolysis in alcohol solvents.327

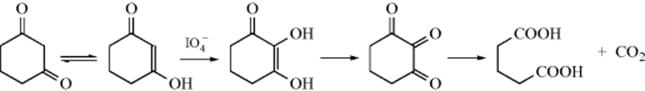

Cyclic 1,3-diketones, which exist mainly in the mono-enolic form, can be cleaved with sodium periodate with loss of one carbon, for example,328

The species actually undergoing the cleavage is the triketone, so this is an example of Reaction 19-7. Cyclic 1,3-diketones are converted to α,ω-diesters with an excess of KHSO5 in methanol.329

OS I, 18; IV, 19; VI, 690. See also, OS VI, 1024.

19-9 Ozonolysis

Oxo-uncoupling

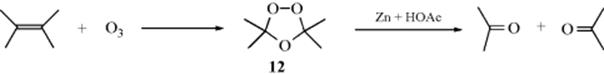

When compounds containing double bonds are treated with ozone, usually at low temperatures, initial formation of a 1,2,3-trioxolane is followed by formation of compounds called 1,2,4-trioxolanes (ozonides, 12). These compounds can be isolated but, because some of them are explosive, they are decomposed with Zn and acetic acid or catalytic hydrogenation. More commonly they are decomposed with DMS330 to give 2 molar equivalents of aldehyde, or 2 molar equivalents of ketone, or 1 molar equivalent of each, depending on the groups attached to the alkene.331 The decomposition of 12 has also been carried out with triethylamine332 and with reducing agents (e.g., trimethyl phosphite333 or thiourea).334 However, ozonides can also be oxidized with oxygen, peroxyacids, or H2O2 to give ketones and/or carboxylic acids. Note that the presence of a hydrogen atom on the C=C unit (C=C–H) leads to differences in oxidation or reduction of 12. In such a system, oxidation leads to the acid, whereas reduction leads to the aldehyde. Note that the presence of a hydrogen atom on the C=C unit (C=C–H) leads to differences in oxidation or reduction of 12. In such a system, oxidation leads to the acid, whereas reduction leads to the aldehyde. It is also possible to reduce 12 with LiAlH4, NaBH4, BH3, or catalytic hydrogenation with excess H2 to give 2 molar equivalents of alcohol.335 Ozonides can be treated with ammonia, hydrogen, and a catalyst to give the corresponding amines,336 or with an alcohol and anhydrous HCl to give the corresponding carboxylic esters.337 Ozonolysis is therefore an important synthetic reaction.338 Ozonolysis can be done in solvent–water mixtures.339

Many alkenes undergo ozonolysis, including cyclic alkenes, where cleavage gives rise to one bifunctional product (an α,ω-difunctional molecule). Alkenes in which the double bond is connected to electron-donating groups react many times faster than those in which it is connected to electron-withdrawing groups.340 Ozonolysis of compounds containing more than one double bond generally leads to cleavage of all the bonds. In some cases, especially when bulky groups are present, conversion of the substrate to an epoxide (15-50) becomes an important side reaction and can be the main reaction.341 Rearrangement is possible in some cases.342 Ozonolysis of triple bonds343 is less common and the reaction proceeds less easily, since ozone is an electrophilic agent344 and prefers double to triple bonds (Sec. 15.B.i). Compounds that contain triple bonds generally give carboxylic acids, although sometimes ozone oxidizes them to α-diketones (Reaction 19-26).

Aromatic compounds are attacked less readily than alkenes, but cleavage is known. Aromatic compounds behave as if the double bonds in the Kekulé structures were really there. Thus benzene gives 3 molar equivalents of glyoxal (HCOCHO), and o-xylene gives a glyoxal/MeCOCHO/MeCOCOMe ratio of 3 : 2 : 1, which shows that in this case cleavage is statistical. With polycyclic aromatic compounds the site of attack depends on the structure of the molecule and on the solvent.345

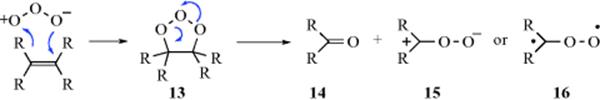

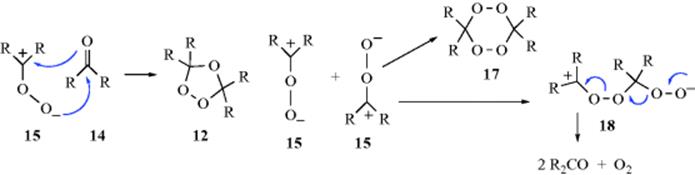

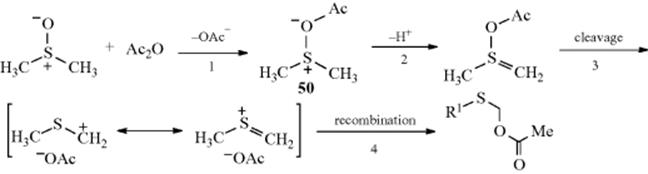

Although a large amount of work has been done on the mechanism of ozonization (formation of 12), not all the details are known. Note that a primary ozonide has been trapped.346 Criegee347 formulated the basic mechanism. The first step of the Criegee mechanism348 is a 1,3-dipolar addition (Reaction 15-58) of ozone to the substrate to give the “initial” or “primary” ozonide, the structure of which has been shown to be the 1,2,3-trioxolane (13) by microwave and other spectral methods.349 However, 13 is highly unstable and cleaves to an aldehyde or ketone (14) and an intermediate350 that Criegee showed as a zwitterion (15), but which may be a diradical (16). This intermediate is usually referred to as a carbonyl oxide.351 The carbonyl oxide, which will be represented as 15, can then undergo various reactions, three of which lead to normal products. One is a recombination with 14, which leads to ozonide 12. The second is a dimerization to the bis(peroxide) 17, and the third a kind of dimerization to 18.352 If the first path is taken (this is normally possible only if 14 is an aldehyde; most ketones do not do this353,354 the product is an ozonide (1,2,4-trioxolane, 12),355 and hydrolysis

of the ozonide gives the normal products. If 17 is formed, hydrolysis of it gives one of the products, and, of course, 14, which then does not undergo further reaction, is the other. If intermediate 18 is formed, direct decomposition is possible, as shown, to give the normal products and oxygen. In protic solvents, 15 is converted to a hydroperoxide, and these have been isolated [e.g., Me2C(OMe)OOH from Me2C=CMe2 in methanol]. Further evidence for the mechanism is that 17 can be isolated in some cases (e.g., from Me2C=CMe2). But perhaps the most impressive evidence comes from the detection of cross-products. In the Criegee mechanism, the two parts of the original alkene break apart and then recombine to form the ozonide. In the case of an unsymmetrical alkene (RCH=CHR′) there should be three ozonides:

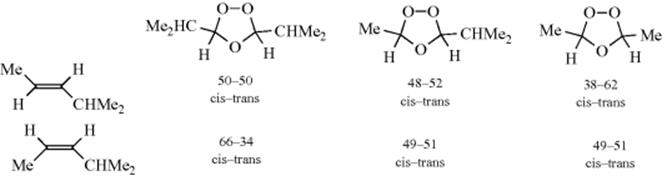

![]()

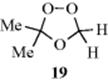

since there are two different aldehydes (14) and two different species (15). These compounds can recombine in the three ways shown. Actually six ozonides, corresponding to the cis and trans forms of these three, were isolated and characterized for methyl oleate.356 Similar results have been reported for smaller alkenes (e.g., 2-pentene, 4-nonene, and even 2-methyl-2-pentene.357 The last-mentioned case is especially interesting, since it is quite plausible that this compound would cleave in only one way, so that only one ozonide (in cis and trans versions) would be found; but this is not so, and three were found for this case too. However, terminal alkenes give little or no cross-ozonide formation.358 In general, the less alkylated end of the alkene tends to go to 14 and the other to 15. Still other evidence359 for the Criegee mechanism is (1) When Me2C=CMe2 was ozonized in the presence of HCHO, the ozonide (19) could be isolated354; (2) 15 prepared in an entirely different manner (photooxidation of diazo compounds), reacted with aldehydes to give ozonides360; and (3) cis-and trans-alkenes generally give the same ozonide, which would be expected if they cleave first.361 However, this was not true for Me3CCH=CHCMe3, where the cis-alkene gave the cis-ozonide (chiefly), and the trans gave the trans.362

The latter result is not compatible with the Criegee mechanism. Also incompatible with the Criegee mechanism was the finding that the cis/trans ratios of symmetrical (cross) ozonides obtained from cis- and trans-4-methyl-2-pentene were not the same.363 If the Criegee mechanism operated as shown above, the cis/trans ratio for each of the two cross ozonides would have to be identical for the cis- and trans-alkenes, since in this mechanism they are completely cleaved.

The above stereochemical results have been explained364 on the basis of the Criegee mechanism with the following refinements: (1) The formation of 13 is stereospecific, as expected from a 1,3-dipolar cycloaddition. (2) Once formed, 15 and 14 remain attracted to each other, much like an ion pair. (3) Intermediate 15 exists in syn and anti forms, which are produced in different amounts and can hold their shapes, at least for a time. This is plausible if we remember that a C=O canonical form contributes to the structure of 19. (4) The combination of 15 and 14 is also a 1,3-dipolar cycloaddition, so configuration is retained in this step too.365

Evidence that the basic Criegee mechanism operates even in these cases comes from ![]() labeling experiments, making use of the fact, mentioned above, that mixed ozonides (e.g., 15) can be isolated when an external aldehyde is added. Both the normal and modified Criegee mechanisms predict that if

labeling experiments, making use of the fact, mentioned above, that mixed ozonides (e.g., 15) can be isolated when an external aldehyde is added. Both the normal and modified Criegee mechanisms predict that if ![]() -labeled aldehyde is added to the ozonolysis mixture, the label will appear in the ether oxygen (see the reaction between 15 and 14), and this is what is found.366 There is evidence that the anti-15 couples much more readily than the syn-15.367

-labeled aldehyde is added to the ozonolysis mixture, the label will appear in the ether oxygen (see the reaction between 15 and 14), and this is what is found.366 There is evidence that the anti-15 couples much more readily than the syn-15.367

The ozonolysis of ethylene368 in the liquid phase (without a solvent) was shown to take place by the Criegee mechanism.369 This reaction has been used to study the structure of the intermediate 15 or 16. The compound dioxirane (20) was identified in the reaction mixture370 at low temperatures and is probably in equilibrium with the biradical 16 (R = H). Dioxirane has been produced in solution, but it oxidatively cleaves dialkyl ethers (e.g., Et–O–Et) via a chain-radical process,371 so the choice of solvent is important.

Ozonolysis in the gas phase is not generally carried out in the laboratory. However, the reaction is important because it takes place in the atmosphere and contributes to air pollution.372 There is much evidence that the Criegee mechanism operates in the gas phase too, although the products are more complex because of other reactions that also take place.373

OS V, 489, 493; VI, 976; VII, 168; IX, 314. Also see, OS IV, 554. For the preparation of ozone, see OS III, 673.

19-10 Oxidative Cleavage of Double Bonds and Aromatic Rings

Oxo-de-alkylidene-bisubstitution, and so on

![]()

Carbon–carbon double bonds can be cleaved by many oxidizing agents,374 the most common of which are permanganate in neutral or acid media and dichromate in acid media. The products are generally 2 molar equivalents of ketone, 2 molar equivalents of carboxylic acid, or 1 molar equivalent of each, depending on what groups are attached to the alkene. With ordinary solutions of permanganate or dichromate, yields are generally low and the reaction is seldom a useful synthetic method; but high yields can be obtained by oxidizing with KMnO4 dissolved in benzene containing the crown ether dicyclohexano-18-crown-6 (see Sec. 3.C.ii).375 The crown ether coordinates with K+, permitting the KMnO4 to dissolve in benzene. Another reagent frequently used for synthetic purposes is the Lemieux-von Rudloff reagent: HIO4 containing a trace of MnO4−.376 The MnO4− is the actual oxidizing agent, being reduced to the manganate stage, and the purpose of the HIO4 is to reoxidize the manganate back to MnO4−. Another reagent that behaves similarly is NaIO4–ruthenium tetroxide.377 Oxidative cleavage of alkenes is catalyzed by Ru with IO(OH)5.378 Cyclic alkenes are cleaved to α,ω-diketones, keto-acids, or dicarboxylic acids. Cyclic alkenes are cleaved to dialdehydes with KMnO4·CuSO4 in dichloromethane.379 A combination of RuCl3/HIO5 oxidatively cleaves cyclic alkenes to dicarboxylic acids.380

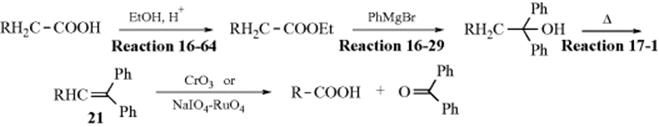

The Barbier–Wieland procedure for decreasing the length of a chain by one carbon involves oxidative cleavage by acid dichromate (NaIO4–RuO4 has also been used), but this is cleavage of a 1,1-diphenyl alkene (21), which generally gives good yields. Addition of a catalytic amount of OsO4 to Jones reagent (Reaction 19-3) leads to good yields of the carboxylic acid from simple alkenes.381 A combination of Oxone and OsO4 in DMF cleaves alkenes to carboxylic acids.382 Cleavage of alkynes is generally rather difficult, but treatment of internal alkynes with an excess of Oxone with a Ru catalyst leads to aliphatic carboxylic acids.383

With certain reagents, the oxidation of double bonds can be stopped at the aldehyde stage, and in these cases the products are the same as in the ozonolysis procedure. Among these reagents are tert-butyl iodoxybenzene,384KMnO4 in THF–H2O,385 and NaIO4–OsO4.386 Enol ethers, [RC(OR′)=CH2] have been cleaved to carboxylic esters [RC(OR′)=O] by atmospheric oxygen.387 Oxidative cleavage of alkenes is catalyzed by a Mn–porphyrin complex.388

The mechanism of oxidation probably involves in most cases the initial formation of a glycol (Reaction 15-29) or cyclic ester,389 and then further oxidation as in Reaction 19-7.390 In line with the electrophilic attack on the alkene, triple bonds are more resistant to oxidation than double bonds. Terminal triple-bond compounds can be cleaved to carboxylic acids with Tl(III)NO3391 or with [bis(trifluoroacetoxy)iodo]pentafluorobenzene [i.e., C6F5I(OCOCF3)2].392

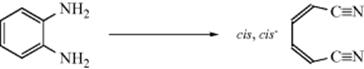

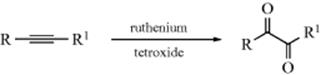

Aromatic rings can be cleaved with strong enough oxidizing agents. An important laboratory reagent for this purpose is RuO4 along with a cooxidant (e.g., NaIO4 or NaOCl and household bleach can be used). Ruthenium tetroxide is an expensive reagent, but the cost can be greatly reduced by the use of an inexpensive cooxidant (e.g., NaOCl), the function of which is to oxidize RuO2 back to ruthenium tetroxide. Examples393 are the oxidation of naphthalene to phthalic acid394 and, even more remarkably, of cyclohexylbenzene to cyclohexanecarboxylic acid395 (note the contrast with Reaction 19-11). The latter conversion was also accomplished with ozone.396 Another reagent that oxidizes aromatic rings is air catalyzed by V2O5. The oxidations of naphthalene to phthalic anhydride and of benzene to maleic anhydride by this reagent are important industrial procedures.397o-Diamines have been oxidized with nickel peroxide, with lead tetraacetate,398 and with O2 catalyzed by CuCl:399

The last-named reagent also cleaves o-dihydroxybenzenes (catechols) to give, in the presence of MeOH, the monomethylated dicarboxylic acids (HO2C–C=C–C=C–CO2Me).400

OS II, 53, 523; III, 39, 234, 449; IV, 136, 484, 824; V, 393; VI, 662, 690; VII, 397; VIII, 377, 490; IX, 530. Also see, OS II, 551.

19-11 Oxidation of Aromatic Side Chains

Oxo,hydroxy-de-dihydro,methyl-tersubstitution

![]()

Alkyl chains on aromatic rings can be oxidized to CO2H groups by many oxidizing agents, including permanganate, nitric acid, and acid dichromate.401 The method is most often applied to the methyl group (CH3 → CO2H), although longer side chains can also be cleaved. Tertiary alkyl groups are resistant to oxidation, and when they are oxidized, ring cleavage usually occurs too.402 It is usually difficult to oxidize an R group on a fused aromatic system without cleaving the ring or oxidizing it to a quinone (Reaction 19-19). However, this has been done (e.g., 2-methylnaphthalene was converted to 2-naphthoic acid) with aq Na2Cr2O7.403 Aryl methyl groups are oxidized to aryl CO2H with NaOCl in acetonitrile,404 or with NBS in aqueous NaOH under photochemical conditions.405 Functional groups can be present anywhere on the side chain and, if in the α position, greatly increase the ease of oxidation. An exception is an α phenyl group. In such cases, the reaction stops at the diaryl ketone stage. Molecules containing aryl groups on different carbons cleave so that each ring gets one carbon atom, as in the cleavage of the 9,10-bond of dihydrophenanthrenes (21 to 22).

It is possible to oxidize only one alkyl group of a ring that contains more than one. The order of reactivity406 toward most reagents is CH2Ar > CHR2 > CH2R > CH3.407 Groups on the ring susceptible to oxidation (OH, NHR, NH2, etc.) must be protected. The oxidation can be performed with oxygen, in which case it is autoxidation, and the mechanism is like that in Reaction 14-7, with a hydroperoxide intermediate.408 With this procedure it is possible to isolate ketones from ArCH2R, and this is often done.409

The mechanism has been studied for the following closely related reaction: Ar2CH2 + CrO3 → Ar2C=O.410 A deuterium isotope effect of 6.4 was found, indicating that the rate-determining step is either Ar2CH2 → Ar2CH· or Ar2CH2 → Ar2CH+. Either way this explains why tertiary groups are not converted to CO2H and why the reactivity order is CHR2 > CH2R > CH3, as mentioned above. Both free radicals and carbocations exhibit this order of stability (Chapter 5). The two possibilities are examples of categories 2 and 3 in Section 19.A. Just how the radical or the cation goes on to the product is not known.

When the alkyl group is one oxidizable to CO2H (Reaction 19-11), cupric salts are oxidizing agents, and the OH group is found in a position ortho to that occupied by the alkyl group.411 This reaction is used industrially to convert toluene to phenol.

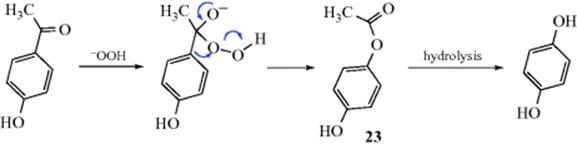

In another kind of reaction, an aromatic aldehyde (ArCHO) or ketone (ArCOR′) is converted to a phenol (ArOH) on treatment with alkaline H2O2,412 but there must be an OH or NH2 group in the ortho or para position. This is called the Dakin reaction.413 The mechanism may be similar to that of the Baeyer–Villiger Reaction (18-19).414 The intermediate 23 has been isolated.415 The reaction has been performed on aromatic aldehydes with an alkoxy group in the ring, and no OH or NH2. In this case, acidic H2O2 was used.416 The Dakin reaction has been done in ionic liquids.417

OS I, 159, 385, 392, 543; II, 135, 428; III, 334, 420, 740, 791, 820, 822; V, 617, 810. OS I, 149; III, 759.

19-12 Oxidative Decarboxylation

Acetoxy-de-carboxy-substitution

![]()

Hydro-carboxyl-elimination

![]()

Carboxylic acids can be decarboxylated418 with lead tetraacetate to give a variety of products: an ester (ROAc), the alkane (RH) (see Reaction 12-40), an alkene if α,β hydrogen is present, as well as numerous other products arising from rearrangements, internal cyclizations,419 and reactions with solvent molecules. When R is tertiary, the chief product is usually the alkene. High yields of alkenes can also be obtained when R is primary or secondary using Cu(OAc)2 along with the Pb(OAc)4.420 In the absence of Cu(OAc)2, primary acids give mostly alkanes (though yields are generally low) and secondary acids may give carboxylic esters or alkenes. Other oxidizing agents,421including Co(III), Ag(II), Mn(III), and Ce(IV), have also been used to effect oxidative decarboxylation.422

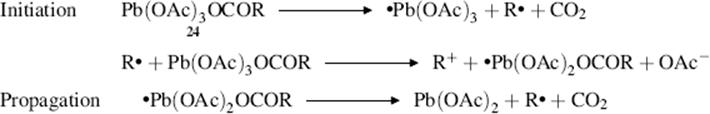

The mechanism with lead tetraacetate is generally accepted to be of the free radical type.423 First, there is an interchange of ester groups:

![]()

A free radical chain mechanism follows (shown for 24 although 25 and other lead esters can behave similarly)

Products can then be formed either from R√ or R+. Primary R√ abstract H from solvent molecules to give RH. The R+ ion can lose H+ to give an alkene, react with HOAc to give the carboxylic ester, react with solvent molecules or with another functional group in the same molecule, or rearrange, thus accounting for the large number of possible products. The radical R√ can also dimerize to give RR. The effect of Cu2+ ions424 is to oxidize the radicals to alkenes, thus producing good yields of alkenes from primary and secondary substrates. The Cu2+ ion has no effect on tertiary radicals, because these are efficiently oxidized to alkenes by lead tetraacetate.

![]()

In another type of oxidative decarboxylation, arylacetic acids can be oxidized to aldehydes with one less carbon (ArCH2COOH → ArCHO) by tetrabutylammonium periodate.425 Simple aliphatic carboxylic acids were converted to nitriles with one less carbon (RCH2COOH → RC![]() N) by treatment with trifluoroacetic anhydride and NaNO2 in F3CCO2H.426

N) by treatment with trifluoroacetic anhydride and NaNO2 in F3CCO2H.426

See also, Reaction 14-37.

19-13 Bis(decarboxylation)

Dicarboxy-elimination

![]()

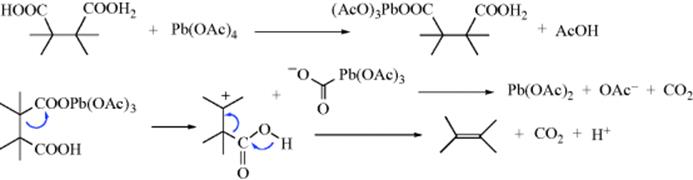

Compounds containing carboxyl groups on adjacent carbons (succinic acid derivatives) can be bis(decarboxylated) with lead tetraacetate in the presence of O2.417 The reaction is of wide scope. The elimination is stereoselective, but not stereospecific (both meso- and dl-2,3-diphenylsuccinic acid gave trans-stilbene)427; a concerted mechanism is thus unlikely. The following mechanism is compatible with the data:

though a free radical mechanism seems to hold in some cases. Bis(decarboxylation) of succinic acid derivatives to give alkenes428 has also been carried out by other methods.429 Compounds containing geminal carboxyl groups (disubstituted malonic acid derivatives) can be bis(decarboxylated) with lead tetraacetate,430gem-diacetates (acylals) being produced, which are easily hydrolyzable to ketones:431

![]()

A related reaction involves α-substituted aryl nitriles having a sufficiently acidic α hydrogen, which can be converted to ketones by oxidation with air under phase-transfer conditions.432 The nitrile is added to NaOH in benzene or DMSO, containing a catalytic amount of triethylbenzylammonium chloride (TEBA).433 This reaction could not be applied to aliphatic nitriles, but an indirect method for achieving this conversion is given in Reaction 19-60.

C. Reactions Involving Replacement of Hydrogen by Heteroatoms

19-14 Hydroxylation at an Aliphatic Carbon

Hydroxylation or Hydroxy-de-hydrogenation

![]()

Compounds containing susceptible C–H bonds can be oxidized to alcohols.434 Nearly always, the C–H bond involved is tertiary, so the product is a tertiary alcohol. This is partly because tertiary C–H bonds are more susceptible to free radical attack than primary and secondary bonds and partly because the reagents involved would oxidize primary and secondary alcohols further. In the best method, the reagent is ozone and the substrate is absorbed on silica gel.435 Yields as high as 99% have been obtained by this method. Other reagents are chromic acid,436 ruthenium tetroxide (RuO4),437 thallium acetate,438 sodium chlorite (NaClO2) with a metalloporphyrin catalyst,439 OsO4,440 and certain peroxybenzoic acids.441 Alkanes and cycloalkanes have been oxidized at secondary positions, to a mixture of alcohols and trifluoroacetates, by 30% aq H2O2 in trifluoroacetic acid.442 This reagent does not oxidize the alcohols further and ketones are not found. As in the case of chlorination with N-haloamines and sulfuric acid (see Reaction 14-1), the ω − 1 position is the most favored. Another reagent443 that oxidizes secondary positions is iodosylbenzene, catalyzed by Fe(III)–porphyrin catalysts.444 Use of an optically active Fe(III)–porphyrin gave modest enantioselective hydroxylation.445

When chromic acid is the reagent, the mechanism is probably as follows: a Cr6+ species abstracts a hydrogen to give R3C√, which is held in a solvent cage near the resulting Cr5+ species. The two species then combine to give R3COCr4+, which is hydrolyzed to the alcohol. This mechanism predicts retention of configuration; this is largely observed.446 The oxidation by permanganate also involves predominant retention of configuration, and a similar mechanism has been proposed.447

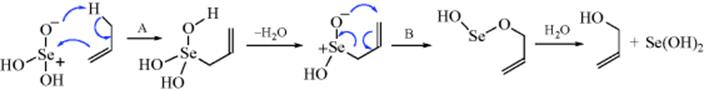

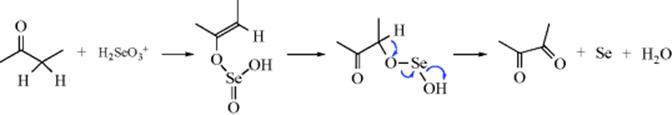

Treatment of double-bond compounds with selenium dioxide introduces an OH group into the allylic position (see also, Reaction 19-17).448 This reaction also produces conjugated aldehydes in some cases.449 Allylic rearrangements are common. There is evidence that the mechanism does not involve free radicals, but includes two pericyclic steps (A and B):450

The step marked A is similar to the ene reaction (Reaction 15-23). The step marked B is a [2,3]-sigmatropic rearrangement (see Reaction 18-35). The reaction can also be accomplished with tert-butyl hydroperoxide, if SeO2 is present in catalytic amounts (the Sharpless method).451 The SeO2 is the actual reagent; the peroxide reoxidizes the Se(OH)2.452 This method makes work up easier, but gives significant amounts of side products when the double bond is in a ring.453 Alkynes generally give α,α′ dihydroxylation.454 Allylic hydroxylation455 with selenium dioxide often gives aldehydes, but in the presence of acetic anhydride and oxygen, SeO2 converts alkenes to homoallylic acetates as the major product, C=C–C–C → C=C–C–C–OAc.456

Hydroxylation of unactivated sp3 hybridized bonds is possible using an oxaziridine-mediated, organocatalyzed reaction.457 Ruthenium tetroxide oxidizes alkanes.458 Nanocrystalline cobalt oxide is another catalyst for alkane oxidation.459 The H2O2–NaVO3–H2SO4 system facilitates alkane oxidation in aqueous acetonitrile.460

Benzylic methylene groups are more readily oxidized to benzylic alcohols when compared to simple alkanes. Typical reagents include manganese salen and PhIO461 or peroxides.462 Oxidation to an acetoxy benzyl derivative was accomplished with PhI(OAc)2 in acetic acid with a Pd catalyst,463 and with PhI(OH)OTs in aq DMSO.464 With minimal water, cerium (IV) triflate converts benzylic arenes to benzylic alcohols, although the major product is the ketone when >15% of water is present.465

Allylic benzyloxylation occurs when an alkene is treated with t-BuOOCOPh and a Cu–Na zeolite,466 a Cu catalyst,467 or with a chiral Cu catalyst to give modest enantioselectivity.468 Allylic methylene groups can be converted to ester (–CH–OCOR) derivatives in a similar manner using copper triflate.469 Cupric acetate has been used,470 as well as Cu2O.471 A chiral Lewis acid has been used for an enantioselective allylic CH oxidation to an allylic acyl derivative.472 α-Acetoxylation of allylic alkenes can proceed with allylic rearrangement.473

Hydroxylation can be accomplished using enzymatic systems. In the presence of Bacillus megaterium and oxygen, cyclohexane is converted to cyclohexanol.474 Allylic oxidation to an allylic alcohol was accomplished with cultured cells of Gossypium hirsutum.475 Benzylic arenes are converted to the corresponding α-hydroxy compound by treatment with the enzymes of B. megaterium, with modest enantioselectivity.476 The reaction of tetradecanoic acid with the α-oxidase from Pisum sativum, in the presence of molecular oxygen, gives 2(R)-hydroxytetradecanoic acid with high asymmetric induction.477

Simple alkanes can be converted to esters with dialkyloxiranes. Cyclic alkanes are oxidized to alcohols with dimethyl dioxirane.478 Cyclohexane was converted to cyclohexyl trifluoroacetate with di(trifluoromethyl) dioxirane and trifluoroacetic anhydride479 and also with RuCl3/MeCO3H/CF3CO2H.480 Dimethyl dioxirane converts alkanes to alcohols in some cases.481 Adamantane is converted to adamantyl alcohol with DDQ (see Reaction 19-1, category 3) and triflic acid.482 The mechanism of oxygen insertion into alkanes has been examined.483

It is possible to perform the conversion CH2 → C=O on an alkane, with no functional groups at all, although the most success has been achieved with substrates in which all CH2 groups are equivalent (e.g., unsubstituted cycloalkanes). Hydrogen peroxide and trifluoroacetic acid has also been used for oxidation of alkanes.484 With this method, cyclohexane was converted with 72% efficiency to give 95% cyclohexanone and 5% cyclohexanol.485 The same type of conversion, with lower yields (20–30%), has been achieved with the Gif system.486 There are several variations. One consists of pyridine–acetic acid, with H2O2 as oxidizing agent and tris(picolinato)iron(III) as catalyst.487 Other Gif systems use O2 as oxidizing agent and Zn as a reductant.488 The selectivity of the Gif systems toward alkyl carbons is CH2 > CH ≥ CH3, which is unusual, and shows that a simple free radical mechanism (see Sec. 14.A.iv) is not involved.489 Another reagent that can oxidize the CH2 of an alkane is methyl(trifluoromethyl)dioxirane, but this produces CH–OH more often than C=O (see Reactions 19-14 and 19-15).490 Cyclic alkanes are oxidized to a mixture of the alcohol and the ketone with PhI(OAc)2 and a manganese complex in an ionic liquid.491 Oxidation of cyclic alkanes to cyclic ketones was accomplished using a Ru catalyst.492

OS IV, 23; VI, 43, 946; VII, 263, 277, 282.

19-15 Oxidation of Methylene to OH, O2CR, or OR

Hydroxy (or alkoxy) -de-dihydro-bisubstitution

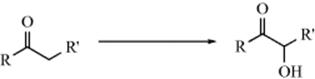

Methyl or methylene groups α to a carbonyl can be oxidized to give α-hydroxy ketones, aldehydes, or carboxylic acid derivatives. Ketones can be α hydroxylated in good yields, without conversion to the enolates, by treatment with the hypervalent iodine reagents493 o-iodosobenzoic acid.494 Dioxygen (O2) and a chiral phase-transfer catalyst gave enantioselective α hydroxylation of ketones, if the α position was tertiary.495 Dimethyl dioxirane is quite effective for hydroxylation of 1,3-dicarbonyl compounds,496 and O2 with a Mn catalyst also gives hydroxylation.497 Oxygen with a Ce catalyst α-hydroxylates β-keto esters.498 The Pd–C catalyzed α-oxygenation of 1,3-dicarbonyl compounds can be accomplished using O2.499 An engineered Cytochrome P450 BM-3 is effective for the enantioselective α-hydroxylation of esters of benzylic acids.500 The reaction of ketones with Ti(OiPr)4, diethyl tartrate and tert-butylhydroperoxide gave the α-hydroxy ketone with good enantioselectively, albeit in low yield.501 α-Hydroxylation of ketones was reported using H2O2 and 12-tungstophosphosphoric acid–cetylpyridinium chloride as a catalyst.502 Hypervalent iodine(III) sulfonate has been used for the α-hydroxylation of aryl ketones.503

Ketones and carboxylic esters can be α hydroxylated by treatment of their enolate anions (prepared by adding the ketone or ester to LDA) with a Mo peroxide reagent (MoO5–pyridine–HMPA; called MoOPH) in THF–hexane at −70°C.504 The enolate forms of amides and esters505 and the enamine derivatives of ketones506 can similarly be converted to their α-hydroxy derivatives by reaction with molecular oxygen. The MoO5 method can also be applied to certain nitriles.507

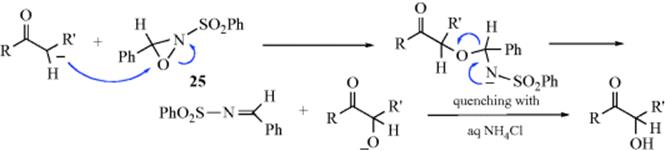

Ketones are converted to α-hydroxy ketones by reaction of the enolate anion with a 2-sulfonyloxaziridine (e.g., 25).508 This is not a free radical process; the mechanism shown is likely. The method is also successful for carboxylic esters509 and N,N-disubstituted amides,510 and can be made enantioselective by the use of a chiral oxaziridine.511 Dimethyldioxirane also oxidizes the enolate anions of ketones to α-hydroxy ketones.512 Titanium enolates are oxidized with tert-butyl hydroperoxide513 or with dimethyldioxirane514 and hydrolyzed with aq ammonium fluoride to give the α-hydroxy ketone. Ketones are converted to the α-oxamino derivative (O=C–CH2– → O=C–CHONHPh) with excellent enantioselectivity using PhN=O and l-proline515 or (S)-proline.516 Aldehydes undergo a similar oxidation.517 α-Lithio sulfones have been hydroxylated with Me3SiOOt-Bu.518

Ketones have been α hydroxylated by conversion to the silyl enol ether, followed by treatment with m-chloroperoxybenzoic acid,166 or with certain other oxidizing agents.519 α-Hydroxyketones can be accomplished from silyl enol ethers with a catalytic amount of MeReO3 and H2O2.520 When the silyl enol ethers are treated with iodosobenzene in the presence of trimethylsilyl trifluoromethyl sulfonate, the product is the α-keto triflate.521 Silyl ketene ethers are converted to α-hydroxy esters with H2O2 and methyl trioxorhenium.522 The α′-position of α,β-unsaturated ketones can be selectively oxidized.523N-Acyl amines are converted to the α-hydroxy derivative with PhIO and a Mn salen catalyst.524 Note that homoallylic-type oxidation occurs when an α,α-dimethyl oxime ether is treated with PhI(OAc)2 and a Pd catalyst in acetic acid/acetic anhydride, converting one of the methyl groups to an acetoxymethyl.525

α-Acetoxylation of ketones with concurrent α-arylation occurs when ketones react with Mn(OAc)3 in benzene.526 α-Acetoxylation of ketones can occur under similar conditions without arylation.527 α-Methyl ketones are converted to the α-acetoxy derivative under the same conditions.528 Iodobenzene with 30% aq H2O2 and acetic anhydride generates α-acetoxy ketones.529 Thallium(III) triflate converts acetophenone to α-formyloxy acetophenone.530Methanesulfonic acid and CuO converts ketones to α-mesyloxy (–OMs) ketones531 and PhI(OH)OTs converts ketones to α-tosyloxy (–OTs) ketones.532 N-Methyl-O-tosylhydroxylamine is another reagent that effects direct α-oxytosylation of ketones and aldehydes.533 α-Acetoxylation of ketones results from in situ generation of hypervalent iodine species in the presence of acetic acid.534

OSCV 7, 277; OSCV 7, 263; OSCV 6, 43

19-16 Oxidation of Methylene to Heteroatom Functional Groups Other Than Oxygen or Carbonyl

Amino (or amido) -de-dihydro-bisubstitution

![]()

α-Amination or amidation of a CH unit is possible in some cases. Cyclic alkanes are converted to the N-alkyl N-tosylamine with PhI=NTs and a Cu complex.535 Benzylic (CH) as in ethylbenzene, is oxidized with PhI(OAc)2 in the presence of TsNH2 and a fluorinated manganese porphyrin to give the corresponding N-tosylamine [PhCHMe(NHTs)].536 Alkenes with an allylic CH react with PhI=NTs and a Ru catalysts to give an allylic N-tosylamine.537 When an α-keto ester reacts with DEAD and a chiral Cu complex, an α-carbamate is formed, RCH(NHCO2Et)C(=O)CO2Et, with modest enantioselectivity.538

Cyclic amines react with Pseudomonas oleovorans GPol to give hydroxy amines; N-benzylpyrrolidine is converted to 3-hydroxy N-benzylpyrrolidine.539 Sphingomonas sp. HXN-200 gives similar results,540 and lactams are converted to the corresponding 3-hydroxy lactam with sphingomonas sp. HXN-200.541 N-Benzyl piperidine is converted to the 4-hydroxy derivative under the same conditions.542 N-Benzyl phthalimide reacts with NBS, NaOAc, and acetic acid to give N-(α-acetoxybenzyl)phthalimide.543

Tetrahydrofuran was converted to the hemiacetal 2-hydroxytetrahydrofuran, which was relatively stable under the conditions used, by electrolysis in water.544 α-Hydroxy ethers are generated by reaction of SO2/O2 and a V catalyst with ethers.545

Similar reactions are possible, in some cases, to produce sulfur containing compounds.

Sulfo-de-dihydro-bisubstitution

![]()

Cyclic alkanes are converted to the corresponding alkylsulfonic acid with SO2/O2 and a V catalyst.546

19-17 Oxidation of Methylene to Carbonyl

Oxo-de-dihydro-bisubstitution

Methyl or methylene groups α to a carbonyl can be oxidized with selenium dioxide to give, respectively, α-keto aldehydes (see Reaction 19-18) and α-diketones.547 The reaction can also be carried out α to an aromatic ring or to a double bond, although in the latter case, hydroxylation (see 19-14) is the more common result. Selenium dioxide, (SeO2) is often used, but the reaction has also been carried out with other oxidizing agents,548 including hypervalent iodine compounds.549 Sodium nitrite/HCl oxidizes cyclic ketones to the diketone.550 Substrates most easily oxidized contain two aryl groups on CH2, and these substrates can be oxidized with many oxidizing agents (see Reaction 19-11). The benzylic position of arenes have been oxidized to alkyl aryl ketones with several oxidizing agents, including the Jones reagent,551 CrO3 on silica,552 PCC,553 DDQ,554 KMnO4 supported on MnO2,555 KMnO4/CuSO4neat556 or with ultrasound,557 manganese salen/PhIO,558 tert-butylhydroperoxide and a Ru catalyst,559 or H2O2 with a Cu catalyst.560 The combination of O2 and mcpba oxidizes benzylic arenes to aryl ketones.561 The combination of HBr and H2O2 gives a similar oxidation.562 Methyl ketones are oxidized to the α-keto ester in a two-step procedure using a fluorous selenic acid with an iodoxy benzene, followed by treatment with sodium metabisulfite (Na2S2O5).563

Alkenes of the form C=C–CH2 (an allylic position) have been oxidized to α,β-unsaturated ketones564 by sodium dichromate in HOAc-Ac2O, by t-BuOOH and Cr compounds,565 t-BuOOH and a Pd566 or Rh567 catalyst. Thallium(III) nitrate in aq acetic acid converts allylic alkenes to the corresponding saturated ketone, even in the presence of a primary alcohol elsewhere in the molecule.568 The propargylic position of internal alkynes are oxidized to give propargylic ketones with an iron catalyst,569 with a dirhodium catalyst in water,570 or with O2/t-BuOOH in the presence of a Cu catalyst.571 Chloramine-T (see Reaction 15-54), O2, and an Fe catalyst give selective oxidation of hydrocarbons to ketones.572

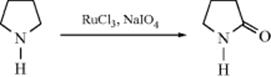

Cyclic amines are oxidized to lactams using a mixture of RuCl3 and NaIO4.573 Lactams are also formed using KMnO4 with benzyltriethylammonium chloride.574 Tertiary amines are converted to amides575 and cyclic tertiary amines can be converted to lactams by oxidation with a Hg(II)–EDTA (EDTA = ethylenediaminetetraacetic acid) complex in basic solution.576 Lactams, which need not be N-substituted, can be converted to cyclic imides by oxidation with a hydroperoxide or peroxyacid and an Mn(II) or Mn(III) salt.577 Lactams are oxidized to cyclic imides with oxygen and Co(OAc)2 in the presence N-hydroxysuccinimide.578

Ethers in which at least one group is a primary alkyl can be oxidized to the corresponding carboxylic esters in high yields with ruthenium tetroxide.579 Molecular oxygen with a binuclear Cu(II) complex580 or PdCl2/CuCl2/CO581also converts ethers to esters. Cyclic ethers are oxidized to lactones.582 Cyclic ethers are oxidized to lactones with CrO3/Me3SiONO2.583 Lactones are also formed from cyclic ethers with NaBrO3–KHSO4 in water.584 The reaction has also been accomplished with CrO3 in H2SO4,585 and with benzyltriethylammonium permanganate.586

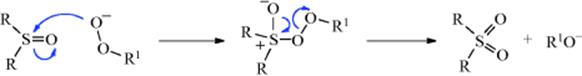

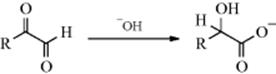

Two mechanisms have been suggested for the reaction with SeO2. One of these involves a selenate ester of the enol:587

In the other proposed mechanism,588 the principal intermediate is α,β-ketoseleninic acid (O=C–CH–SeO2H) and a selenate ester is not involved.

Oxidation of CH2 to C=O groups is possible even if they are not near any functional groups, indirectly, by the remote oxidation method of Breslow57 (see Reaction 19-2). One of the CH2 groups of n-hexadecanol monosuccinate [CH3(CH2)14CH2OCOCH2CH2CO2H] was oxidized to a C=O group to give a mixture of it and benzophenone-4-carboxylic acid [p-PhCOC6H4CO2H] in CCl4.589 Other remote oxidations590 also have been reported. Among these are conversion of aryl ketones [ArCO(CH2)3R] to 1,4-diketones [ArCO(CH2)4COR] by photoirradiation in the presence of such oxidizing agents as K2Cr2O7 or KMnO4,591 and conversion of alkyl ketones [RCO(CH2)3R′] to 1,3- and 1,4-diketones with Na2S2O8 and FeSO4.592 2-Octanol was oxidized to give 2-propyl-5-methyl γ-butyrolactone with lead tetraacetate in a CO atmosphere.593

OS I, 266; II, 509; III, 1, 420, 438; IV, 189, 229, 579; VI, 48; IX, 396. Also see, OS IV, 23.

19-18 Oxidation of Arylmethanes to Aldehydes

Oxo-de-dihydro-bisubstitution

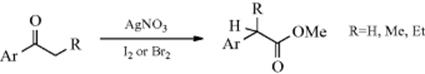

![]()

Methyl groups on an aromatic ring can be oxidized to an aldehyde by several oxidizing agents. The reaction is a special case of 19-17. When the reagent is chromyl chloride (CrO2Cl2), the reaction is called the Étard reaction594and the yields are high.595 Another oxidizing agent is a mixture of CrO3 and Ac2O, where the reaction stops at the aldehyde stage because the initial product is ArCH(OAc)2 (an acylal), which is resistant to further oxidation. Hydrolysis of the acylal gives the aldehyde.

Among other oxidizing agents596 that have been used to accomplish the conversion of ArCH3 to ArCHO are ceric ammonium nitrate,597 PCC,598 hypervalent iodoso compounds (see Reaction 19-3),599 Bi-t-BuOOH,600 and urea–H2O2 with microwave irradiation.601 Oxidative of benzylic positions to the corresponding carbonyl has been reported using two heterogeneous catalysts.602 Oxidation of ArCH3 to carboxylic acids is considered at Reaction 19-11.

Conversion of ArCH3 to ArCHO can also be achieved indirectly by bromination to give ArCHBr2 (14-1), followed by hydrolysis (Reaction 10-2).

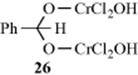

The mechanism of the Étard reaction is not completely known.603 An insoluble complex is formed on addition of the reagents, which is hydrolyzed to the aldehyde. The complex is probably a kind of acylal, but the identity of the structure is not fully settled, although many proposals have been made as to its structure and as to how it is hydrolyzed. It is known that ArCH2Cl is not an intermediate (see Reaction 19-20), since it reacts only very slowly with chromyl chloride. Magnetic susceptibility measurements604 indicate that the complex from toluene is 26, a structure first proposed by Étard. According to this proposal, the reaction stops after only two hydrogen atoms have been replaced because of the insolubility of 26. There is a disagreement on how 26 is formed, assuming that the complex has this structure. Both an ionic605 and a free radical606 process have been proposed. An entirely different structure for the complex was proposed by Nenitzescu et al.607 On the basis of ESR studies, they proposed that the complex is PhCH2OCrCl2OCrOCl2OH, which is isomeric with 26. However, this view has been challenged by Wiberg and Eisenthal,606 who interpret the ESR result as being in accord with 26. Still another proposal is that the complex is composed of benzaldehyde coordinated with reduced chromyl chloride.608

OS II, 441; III, 641; IV, 31, 713.

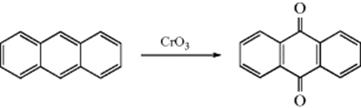

19-19 Oxidation of Aromatic Hydrocarbons to Quinones

Arene-quinone transformation

Condensed aromatic systems (including naphthalenes) can be directly oxidized to quinones by various oxidizing agents.609 Yields are generally not high, although good yields have been reported with ceric ammonium sulfate.610Benzene cannot be so oxidized by strong oxidizing agents, but can be electrolytically oxidized to benzoquinone.611 Naphthalene derivatives, however, are oxidized to naphthoquinones with H5IO6 and CrO3.612 1,4-Dimethoxy aromatic compounds are oxidized to p-quinones with an excess of CoF3 in water–dioxane.613

OS IV, 698, 757. Also see, OS II, 554.

19-20 Oxidation of Primary Halides and Esters of Primary Alcohols to Aldehydes614

Oxo-de-hydro,halo-bisubstitution

![]()

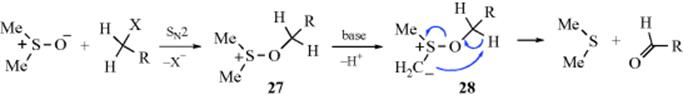

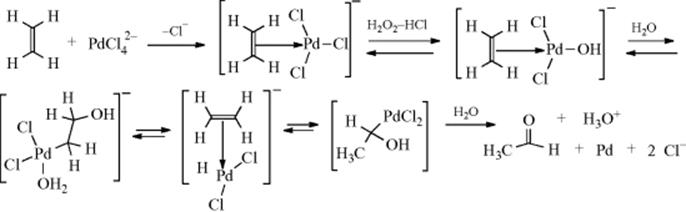

Primary alkyl halides (chlorides, bromides, and iodides) can be oxidized to aldehydes easily and in good yields with DMSO,615 in what has been called the Kornblum reaction. In Kornblum's original work, the reaction of α-halo ketones with DMSO at elevated temperatures gave good yields of the corresponding glyoxal (an α-keto-aldehyde).616 If the glyoxal could be removed from the reaction medium by distillation as it was formed, the reaction was very efficient. In many cases, it was difficult to isolate high-boiling glyoxals from DMSO. Primary and secondary617 alkyl iodides or tosylates618 can be converted to aldehydes or ketones, although they are much less reactive than α-halo ketones. Primary chlorides with DMSO, NaBr, and ZnO give the corresponding aldehyde when heated to 140 °C.619 Benzylic halides are oxidized to aryl aldehydes with MnO2620 or with NaIO4–LiBr.621 Hydrogen peroxide in ethanol oxidizes organic halides to carbonyl compounds.622 Pyridine N-oxide in the presence of silver oxide oxidizes benzylic and allylic halides.623

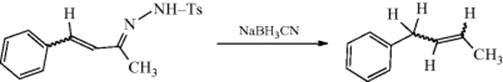

The mechanism of these DMSO oxidations is probably that shown with 27 and 28,624 although in some cases the base abstracts a proton directly from the carbon being oxidized, in which case the ylid (28) is not an intermediate. Alkoxysulfonium salts (27) have been isolated.625 This mechanism predicts that secondary compounds should be oxidizable to ketones, and this is the case. In a related procedure for the oxidation of alcohols, the intermediate 27626is formed without the use of DMSO by treating the substrate with a complex generated from chlorine or NCS and DMS.627 Also see the Swern oxidation in Reaction 19-3.