CHEMICAL BIOLOGY

Naturally Occurring Peptide Hormones and Neurotransmitters, Synthesis of

Zhihua Liu and Victor J. Hruby, Department of Chemistry, The University of Arizona, Tucson, Arizona

doi: 10.1002/9780470048672.wecb658

How to synthesize biologically active polypeptides chemically has long been an important challenge for many fields in chemistry and biology. In the past, the development of solution-phase and solid-phase synthesis techniques has made it possible to synthesize large molecules like peptides with molecular weights up to 10,000. The purpose of this review is to provide an overview of how to prepare natural bioactive peptides synthetically. Because of space limitations, this review concentrates on peptide hormones and neurotransmitters.

Abbreviations: Standard abbreviations as recommended by IUPAC-1UB Commission are used in this review (1). Other abbreviations include: Acm, acetamidomethyl; Bn, benzyl; Boc: t-butyloxycarbonyl; Bom, benzyloxymethyl; BHA, benzhydrylamine; Cbz, benzyloxycarbonyl; cHx, cyclohexyl; DCC, N,N-dicyclohexylcarbodiimide; DCM, dichloromethane; DIC, N,N-diisopropylcarbodiimide; DMF, N,N-dimethylformamide; DMSO, dimethyl sulphoxide; For, formyl; Fmoc, 9-fluorenylmethyloxycarbonyl; HMP, 4-hydroxymethylphenoxyacetyl; HOAt, 1-hydroxy-7-azabenzotriazole; HOBt, 1-hydroxybenzotriazole-benzotriazole; MBHA, 4-methylbenzhydrylamine; Mtr, 4-methoxy-2,3,6-trimethylphenylsulphonyl; Np, nitrophenyl; NSu, N-succinimide; ONsu, N-hydroxysuccinimide; Trt, triphenylmethyl; Pam, 4-(hydroxymethyl) phenylacetamidomethyl; PAL, 5-[4-(9-fluorenylmethyloxycarbonyl)aminomethyl-3,5,-dimethoxyphenoxy]valeric acid; Pcp, pentachlorophenyl; PEG, polyethylene glycol; Pha, phenoxyacetyl; Pmc, 2,2,5,7,8-pentamethyl-chroman-6-sulphonyl; Tcp, trichlorophenyl; TFA, trifluoroacetic acid; TFAA, trifluoroacetic anhydride; Tos, p-toluenesulfonyl.

Peptide hormones and neurotransmitters are among the most important classes of natural products in living systems, including in humans. They modulate and regulate most major biological functions and behaviors that are necessary for the maintenance of life and health, including feeding behavior, reproduction, response to stress, pain, cardiovascular function, kidney function, energy homeostasis, aggression, maternal behavior, learning behavior, and many others. In addition, these hormones often are intimately involved in virtually all major diseases, including hypertension and other cardiovascular dysfunctions, diabetes, obesity, cancer, CNS diseases, and many others. The recognition

that polypeptides played such a central role in health and disease is a relatively recent scientific development. The discovery of insulin as the principle modulator (along with glucagon—a later discovery) of glucose levels in the blood and the determination of the structure and total synthesis of the peptide hormone and neurotransmitter oxytocin, which controls uterine contraction, milk ejection, and later maternal behavior; socialization; and aspects of sexual behavior are milestones not only in peptide and protein chemistry, biology, and medicine, but also in modern drug discovery and design. Especially in the case of oxytocin immediately after its structure determination and total synthesis by du Vigneaud and co-workers in the early 1950s, he and many others began to modify the “functional groups” and structure of oxytocin to determine those features important to biological activity. Of central importance in this regard was the development of increasingly efficient synthetic methods (if you cannot make it you cannot study it) and analytical methods for the preparation and purification of polypeptides. In this review, we will outline synthetic methods that have been developed for the synthesis of polypeptide hormones and neurotransmitters, and in the process we also point out the key analytical procedures that have been used in the synthesis and purification of these important biological natural products. See Table 1 for an overview of this article and its contents.

Table 1. Peptides discussed in this article

|

Name |

Target |

Structure features |

Major biological activities |

Synthesis techniques |

|

Atrial natriuretic peptide (ANP)

Cholecystokinin (CCK)

Gastrin

Glucagon-like peptide 1 (GLP1)

Glucose-dependent insulinotropic polypeptide (GIP) Motilin Neuropeptide Tyrosine (NPY) Peptide Tyrosine Tyrosine (PYY) Secretin Somatostatin

Substance P

Vasoactive intestinal peptide (VIP)

Corticotropin-releasing factor (CRF or CRH) Gonadotropin-releasing factor (GnRF or GnRH)

Growth hormone releasing factor (GRF or GRH) Thyrotropinreleasing factor

Angiotensin II Amylin

Glucagon Insulin

Pancreatic polypeptide

Adrenocorticotropin (ACTH) Melanocyte-stimulating hormones (MSH)

Oxytocin

Vasopressin

Relaxin

Calcitonin

Calcitonin gene-related peptide (CGRP)

Dynorphin

Endorphin

Enkephalin

Leumorphin

Neurokinin A & B Eledoisin, Physalaemin and Kassinin Gastrin releasing peptide (GRP) Neurotensin

Bradykinin |

ANP-R1 to R3 receptors in the peripheral system CCK-A receptor, CCK-B receptor

CCK-B receptor

GLP-1 receptor

GIP receptor

Motilin receptor NP Y1 to Y5 receptors PYY receptor Secretin receptor Somatostatin 1 to 5 receptors

Neurokinin 1 receptor

VPAC1 and VPAC2 receptors

CRH-R1 and CRH-R2 receptors

GnRH I and II receptor

GRH receptor

TRF receptor

Angiotensin II AT1 and AT2 receptor Amylin receptor

Glucagon receptor Insulin receptor

Pancreatic polypeptide receptor, NP Y4 receptor Melanocortin 2 receptor Melanocortin 1 to 5 receptors

Oxytocin receptor

Arginine vasopressin receptor 1A, 1B, 2 Relaxin/insulin-like family peptide receptor 1 to 4

Calcitonin receptor

CGRP1 and 2 receptors

k-opioid receptor

μ,δ-opioid receptors

μ,δ-opioid receptors

k-opioid receptor

Neurokinin 1 to 3 receptors Neurokinin 1 to 3 receptors Gastrin-releasing peptide receptor Neurotensin 1, 2 receptors, Sortilin 1 receptor Bradykinin 1, 2 receptors |

28-residue peptide with a disulfide bridge 33-residue peptide amide with a Tyr sulfonic acid 14- and 17-residue peptide amide with a Glu rich region 30- and 31-residue peptide amide differed by a C-terminal Gly 42-residue peptide

22-residue peptide 36-residue peptide amide 36-residue peptide amide 27-residue peptide amide 14- and 28-residue peptide with a disulfide bridge 11-residue peptide amide

28-residue peptide amide, highly basic 41-residue peptide amide

10-residue peptide amide

40-44-residue peptide amide

3-residue peptide amide

8-residue peptide 37-residue peptide amide with one disulfide bridge 29-residue peptide Contains 21-residue A chain with an intra disulfide bridge and 30-residue B chain, linked by two disulfide bridges 36-residue peptide amide

39-residue peptide 12-22-residue peptide or peptide amide, with His-Phe-Arg-Trp as the major pharmacophore 9-residue peptide amide with a disulfide bridge 9-residue peptide amide with a disulfide bridge Contains 24-residue A chain with an intra disulfide bridge and 29-residue B chain, linked by two disulfide bridges 32-residue peptide amide with a disulfide bridge 37-residue peptide amide with a disulfide bridge 13- or 17-residue peptides

16- to 31-residue peptides

5-residue peptides different at the C –termili sequence 29-residue peptide

10-residue peptide amide 10- or 11-residue peptide amide 27-residue peptide amide 13-residue peptide

9-residue peptide |

Modulate blood pressure

Modulate digestion system

Stimulate gastric acid secretion

Stimulate insulin secretion

Inhibit gastric acid and stimulate insulin secretion Stimulate migrating motor complex Increase food intake Inhibit food digestion Regulate pH of duodenal contents Inhibit gut peptides and growth hormone Involved in pain, vomitting, cellular growth, mood regulation Inhibit gastric acid and stimulate water and electrolytes secretion Involved in stress response

Stimulate the release of luteinizing hormone and follicle-stimulating hormone Stimulates growth hormone secretion

Stimulates thyroid- stimulating hormone and prolactin secretion Increase blood pressure Regulate blood glucose level

Increase blood glucose level Lower blood glucose level

Inhibit pancreatic secretion

Stimulate the cortex of adrenal gland Darken skin and hair

Facilitate birth and breastfeeding

Regulate the retention of water

Facilitate birth

Lower blood calcium and phosphate levels Lower blood pressure

Endogenous k-opioid receptor agonist Have analgesic effect

Have analgesic effect

Endogenous k-opioid receptor agonist Similar activities as substance P Similar activities as substance P Stimulate gastrin release Lower blood pressure, increase blood glucagon, glucose levels Lower blood pressure, pain related |

Solid-phase Na-Boc chemistry

Solution-phase and solid-phase Na–Boc chemistry Solution-phase and solid-phase Na–Fmoc chemistry Solid-phase Na–Fmoc chemistry

Solution-phase chemistry

Solid-phase Na-Boc chemistry Solid-phase Na-Boc chemistry Solid-phase Na-Fmoc chemistry Solid-phase Na-Boc chemistry Solid-phase Na-Boc chemistry

Solid-phase Na-Boc chemistry

Solid-phase Na-Boc chemistry

Solid-phase Na-Boc chemistry

Solid-phase Na-Boc chemistry

Solid-phase Na-Boc chemistry

Solid-phase Na-Boc chemistry

Solid-phase Na-Boc chemistry Solid-phase Na-Boc chemistry

Solid-phase Na-Boc chemistry Solid-phase Na-Boc chemistry

Solid-phase Na-Boc chemistry

Solid-phase Na-Boc chemistry Solid-phase Na-Boc chemistry

Solid-phase Na–Boc chemistry

Solid-phase Na-Boc chemistry

Solid-phase Na-Fmoc and Na–Boc chemistry

Solid-phase Na-Fmoc chemistry

Solid-phase Na-Boc chemistry

Solid-phase Na–Fmoc chemistry

Solid-phase Na-Fmoc and Na-Boc chemistry Enzymetic synthesis

Solid-phase Na-Boc chemistry

Solid-phase Na-Boc chemistry Solid-phase Na-Boc chemistry Solid-phase Na–Boc chemistry

Solid-phase Na–Boc chemistry |

Atrial natriuretic peptide (ANP)

ANP is a 28-amino-acid peptide first discovered by de Bold et al. (2). It is released from heart atrial myocytes in response to a local arterial wall stretch. ANP acts on outer adrenal cells to decrease aldosterone production and blood pressure, increase salt and water excretion, and transudate plasma water to the interstitium (3).

The sequence of ANP is as follows: Ser-Leu-Arg-Arg-Ser-Ser-c(Cys-Phe-Gly-Gly-Arg-Ile-Asp-Arg-Ile-Gly-Ala-Gln-Ser-Gly-Leu-Gly-Cys)-Asn-Ser-Phe-Arg-Tyr-OH.

The structure of ANP shows a disulfide ring at position 7 to 23, which is shared by the other two natriuretic peptides (brain natriuretic peptide and C-type natriuretic peptide). ANP has been prepared synthetically via solid-phase peptide synthesis using the Na-Boc strategy. von Geldern et al. (4) used a Biosearch Model 9500 automated synthesizer (Biosearch Technologies, Novato, CA) to assemble the amino acid sequence on a Merrifield resin preloaded with Na-Boc-Tyr. A standard protocol for solid-phase synthesis (DCC/HOBt as coupling reagents; TFA for Na-Boc removal) and side-chain protections was used (refer to the sections on “Somatostatin synthesis” and “Angiotensin II synthesis” for details). The peptide was cleaved from the resin, and all protecting groups were deprotected with anhydrous HF that contained 10% anisole. The crude peptide was extracted with acetic acid, and the disulfide bond was formed by oxidation with iodine (0.01 N in ethanol; ~2 eq.) for 1 hour; excess iodine was removed by addition of aqueous sodium thiosulfate until the solution was colorless. The crude ANP was first purified on a column of Amberlyst XAD-16 nonionic adsorbent, and finally by high-performance liquid chromatography (HPLC) using a C-18 column, obtaining a more than 95% pure product.

Gut peptide hormones

Cholecystokinin (CCK)

CCK is a 33-amino-acid peptide hormone first isolated from porcine intestinal mucosa a long time ago (5). It exists in both the brain and the gastrointestinal systems, and it is responsible for central and pancreatic biological effects, including stimulating gallbladder contraction and bile flow and increasing the production of pancreatic digestive enzymes.

The sequence of porcine cholecystokinin-33(CCK-33) is as follows: Lys-Ala-Pro-Ser-Gly-Arg-Val-Ser-Met-Ile-Lys-Asn-Leu-Gln-Ser-Leu-Asp-Pro-Ser-His-Arg-Ile-Ser-Asp-Arg-Asp-Tyr(SO3H)-Met-Gly-Trp-Met-Asp-Phe-NH2.

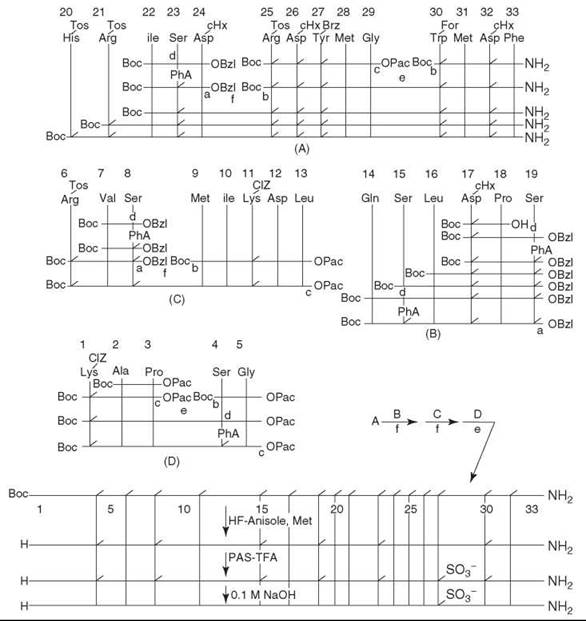

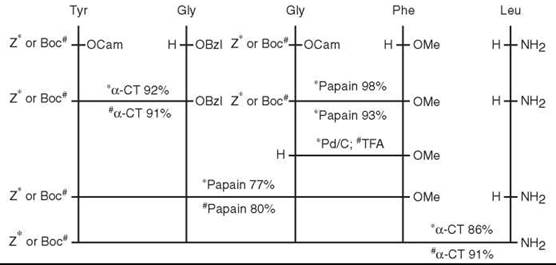

Although discovered in the 1920s, the relatively long sequence and a tyrosine sulfonic acid residue make CCK a challenge for chemical synthesis compared with gastrins, which are related peptides that share identical C-termini. The first successful synthesis was not reported until Sakakibara’s group announced a solution-phase synthesis (6) in 1987, and in the same year, Penke’s group reported another successful synthesis by employing the solid-phase method (7). In the solution-phase study, the peptide was prepared via classic procedures. The Na-Boc proctected amino acids were coupled with the water-soluble carbodiimide (WSCI), 1-ethyl-3-(3-dimethylaminopropyl) carbodiimide, and HOBt (WSCI-HOBT method) (6). The coupling of protected peptides with L-amino acid residues at the C-terminus was carried out using WSCI together with 3,4-dihydro-3-hydroxy-4-oxo-1,2,3-benzotriazine (HOOBT), which is known to minimize racemization of activated amino acid residues (WSCI-HOOBT method) (6). The side-chain protections were as follows: Asp was protected by a cHx group; Arg and His by Tos groups; Lys by a Cl-Cbz group; Tyr by a Br-Cbz group; Ser by a Pha group; Trp by a For group. The fully protected peptide thus obtained was deprotected by HF in the presence of anisole and Met. The Pha and For groups were not removed under these conditions. The Tyr residue was then sulphated with 40 equivalents of pyridinium acetylsulphate in TFA in an ice bath for 2 hours. After precipitation by adding water, the product was treated with 40 equivalents of 0.1 M NaOH in DMSO in an ice bath for 10 minutes to remove the remaining Pha and For groups. The crude product was purified by CM-cellulose chromatography and then by reversed-phase HPLC to produce a homogeneous preparation of the final product with only a 5% yield from the fully protected peptide. The scheme for the synthesis is shown in Fig. 1.

Figure 1. Scheme for the synthesis of porcine CCK-33. Peptide coupling was done by the WSCI-HOBT method unless otherwise indicated. (a) Catalytic hydrogenolysis. (b) TFA. (c) Zn-acetic acid. (d) phenoxyacetic anhydride. (e) WSCI-HOBY. (f) WSCI-HOOBT. OPac = phenacyl. Taken from Kurano et al. (6).

Penke’s group has reported two successful solid-phase syntheses of this peptide. The first study was using the Na-Boc chemistry published in 1987, with an overall yield of 1%. In 1991, they announced another synthesis using the Na-Fmoc strategy, and the protected Tyr(SO3H) was introduced into the peptide sequence during the chain assembly (8). A new solid support system, 4-succinylamido-2,2’,4’-trimethoxybenzhydrylamine (SAMBHA)-polystyrene resin, was also made for the synthesis to accommodate the acid-labile sulfate ester.

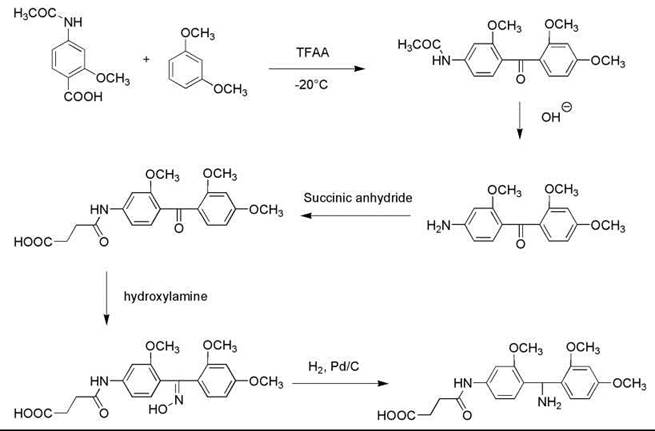

The anchor SAMBHA was prepared through a five-step synthesis (Fig. 2). First, 2-methoxy-4-acetamidobenzoic acid (0.03 mol) was dissolved at -20 °C in TFAA (15 mL) and reacted at 0 °C for 20 minutes. Then the mixture was dissolved in nitromethane (10 mL) and reacted with 2,4-dimethoxybenzene (0.035 mol) at room temperature for 25 minutes, followed by adding ice and ethylacetate and 10% sodium carbonate solution to neutralize the substance. The organic phase was washed three times with sodium carbonate solution and once with H2O and dried over sodium sulfate. After removing the solvents in vacuo, the oily residue was crystallized by triturating with ether, obtaining 2,2’,4’-trimethoxy-4-acetamidobenzophenone. The product was then dissolved in a mixture of 4N NaOH (30 mL) and methanol (30 mL) and was refluxed for 1 hour. Methanol was removed in vacuo, and 2,2’,4’-trimethoxy-4-aminobenzophenone was precipitated from the solution. After filtration and washing with H2O, the white crystals (0.01 mol) were dried, dissolved in pyridine (10 mol), and acylated with succinic anhydride (0.02 mol) by refluxing for 15 minutes. Pyridine was removed in vacuo; the oily residue was dissolved in a 1:1 mixture of ethyl acetate and 1 N HCl. The organic phase was separated, washed with H2O, dried over sodium sulfate, and evaporated to half volume. Ether was added, and the product 2,2’,4’-trimethoxy-4-succinylamidobenzophenone was precipitated as white crystals. The product (0.026 mol) was then dissolved in a mixture of pyridine (7.5 mL) and ethanol (50 mL), and it was refluxed for 45 minutes with hydroxylamine hydrochloride (0.067 mol). The solvent was then removed in vacuo, and the oily residue was triturated with 5% aqueous KHSO4 solution. The resulting solid was filtered, washed with H2O, and dried, obtaining 2,2',4'-trimethoxy-4-succinylamidobenzophenone oxime. The oxime (5 mmol) was suspended in glacial acetic acid (200 mL) and dissolved by warming. Then, 1-mL concentrated HCl and 0.2-g freshly prepared Pd-Catalyst were added, and the oxime was hydrogenated under pressure (1 M Pascal) for 5 hours. After filtering the catalyst and removing the solvents in vacuo, the oily residue was triturated with ether; the final product SAMBHA hydrochloride was crystallized as white solid. Four-mmol SAMBHA hydrochloride was then reacted overnight with Fmoc-OSu (4.4 mmol) in a mixture of H2O (5 mL) and dioxane (15 mL) in the presence of sodium bicarbonate (670 mg) to get Fmoc-SAMBHA, which was used to couple with aminomethyl polystyrene suspended in DCM in the presence of DCC in DMF. After 12 hours of reaction, the resin was washed with a 1:1 mixture of DMF and DCM, and the coupling reaction was repeated with Fmoc-SAMBHA and DCC. The Na-Fmoc group was cleaved by 10 minutes of treatment with 20% piperidine in DMF, and the SAMBHA resin was obtained with 0.33-mmol/g loading.

Figure 2. Synthesis of 4-succinylamido-2,2',4'-trimethoxybenzhydrylamine (SAMBHA).

Na-Fmoc-Tyr(SO3Na)OH was prepared by reacting tyrosine with chlorosulfonic acid in TFA at -20 °C for 5 minutes. Then Na-Fmoc group was added by reacting with Fmoc-Cl in a mixture of 10% sodium carbonate solution and dioxane.

The peptide was assembled using an Applied Biosystems 430A automatic peptide synthesizer (Applied Biosystems, Inc., Foster City, CA), and the SAMBHA-polystyrene resin was used as solid support. Amino acids were coupled as symmetric anhydrides using DCC in a 1:1 mixture of DCM-DMF or in pure DMF as coupling reagent, except that Na-Fmoc-Asp(Ot-Bu) and Na-Fmoc-Glu(Ot-Bu) were coupled as HOBt active esters and Na-Fmoc-Tyr(SO3Na) as a petafluorophenyl ester. The side-chain protections were as follows: Asp and Ser were protected by f-Bu groups; His by a Fmoc group; Lys by a Boc group; Arg by a Pmc group. Coupling was repeated if a ninhydrin test was positive. After completion of the synthesis, the peptide resin was washed with a 1:1 mixture of DMF-methanol that contained 0.4 g of NaOH for 1 minute, methanol for 2 minutes, and ether (4 x 2 minutes). Then the resin was dried. The protected pCCK-33 sulfate ester resin was washed with DCM (4 x 2 min) and was treated two times with 12 mL of 50% TFA solution in DCM that contained 5% ethanedithiol and 2% dimethyl sulfide (1 x 1min, 1 x 15 min, 1 x 1min). The TFA-containing solutions were pooled, and solvents were evaporated in vacuo. pCCK-33 was precipitated by adding peroxide-free ether.

Crude pCCK-33 was dissolved in the mixture of acetonitrile and 0.05 M (pH = 6.5) ammonium acetate buffer and was purified by prep-HPLC on a C18 column. The synthetic peptide was identified by using the native pCCK-33 standard. Pure fractions were pooled and lyophilized three times.

Gastrin

In 1905, Edkins discovered a hormone from the stomach and named it gastrin. Different forms and fragments of gastrin have been reported since then. The characteristic forms include a

17-residue amide called little gastrin and a 14-residue amide called minigastrin, which were known for their abilities of stimulating acid, pepsin, and pancreatic secretions in response to food (9).

The sequence of human little gastrin is as follows: pyroGlu-Gly-Pro-Trp-Leu-Glu-Glu-Glu-Glu-Glu-Ala-Tyr-Gly-Trp-Met-Asp-Phe-NH2.

The sequence of human minigastrin is as follows: Trp-Leu-Glu-Glu-Glu-Glu-Glu-Ala-Tyr-Gly-Trp-Met-Asp-Phe-NH2.

Gastrins and gastrin analogs have drawn great interest from chemists, and many total synthesis studies have been reported. Solution-phase synthesis was achieved by Anderson et al. in the 1960s (10). In 1980, Brown and coworkers reported a solid-phase synthesis of these two peptide amides (11). Methoxycarbonyl-functionalized polydimethylacrylamide resin was chosen as the solid support. It was converted into a primary amine by treating it with ethylenediamine. An internal reference-spacer amino acid was incorporated by couping with Na-Fmoc-norleucine anhydride and the cleavage of the Na-Fmoc group with 20% piperidine, followed by the addition of the reversible-linkage agent [2,4,5-trichlorophenyl 4-(hydroxymethyl)benzoate] in the presence of HOBt.

The peptide sequence was then assembled using initially Na-Boc-Phe anhydride in the presence of catalyst (dimethylaminopyridine) to establish the peptide-resin ester bond, followed by 16 cycles of Na-Fmoc amino-acid coupling. The symmetric anhydride method was used for coupling in all cases except for the last Gln, which was introduced as its p-nitrophenyl ester in the presence of HOBt. Deprotection of the Na-Boc groups was done by treating with HCl-AcOH, whereas the Na-Fmoc groups were removed by 20% piperidine in DMF. Gln was chosen as the N-terminal residue rather than pyroglutamic acid, which is present in little gastrin, so as to permit possible future extension into the prohormone series. Side-chain protections were as follows: Asp, Tyr, and Glu were protected by t-butyl groups. After completing the synthesis, side-chain t-butyl derivatives were removed by treatment with 90% aqueous TFA, and the free peptide was released from the resin by ammonolysis in saturated methanolic ammonia for 22 hours. Residual resin analysis indicated the removal of 91% of the peptide. At this stage, the product consisted of a mixture of the 17-residue N-terminal glutamine peptide amide and its cyclized pyroglutamyl analog (5:1). Cyclization was brought nearly to completion by treatment with 20% acetic acid (30 °C, 64 hours under Argon).

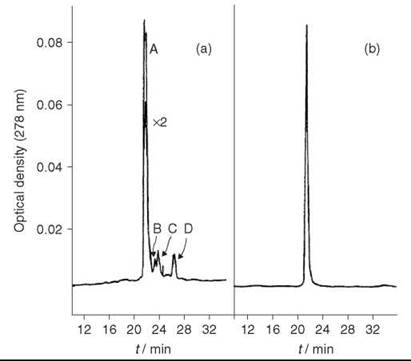

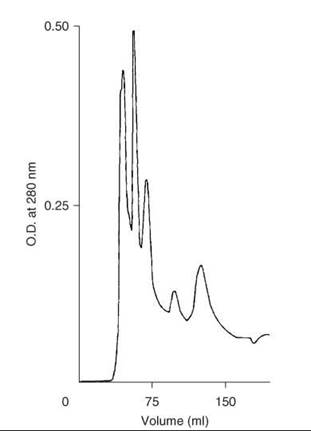

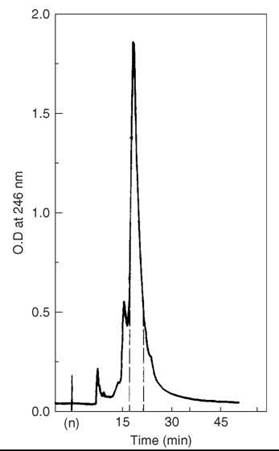

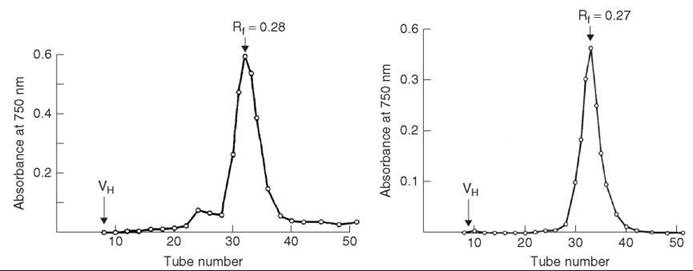

HPLC analysis showed the crude peptide has three major impurity peaks (Fig. 3a). The residual glutaminyl peptide (peak C) was removed by ion-exchange chromatography on DEAE cellulose DE52 (linear gradient of 0.01-1 M NH4OAc, pH 6.5); the impurities (peaks B and D) were removed by preparative HPLC on μ-Bondapak C-18 column using linear gradient of 18-45% MeCN in 0.01 M NH4OAc, pH 3.5, over 30 minutes, flow rate 2mL/min. The yield of purified [15-leucine] human little gastrin (Fig. 3b), which is identical by PHLC and TLC with an authentic sample, was 32%.

Minigastrin was obtained by stopping the peptide chain elongation after addition of the 14th residue; cleavage, deprotection, and HPLC purification were done similarly as mentioned above.

Figure 3. (a) HPLC analysis of crude little gastrin. (b) HPLC analysis of purified little gastrin. Taken from Brown et al. (11).

Glucagon-like peptide 1 (GLP1)

GLP1 is a peptide hormone produced by the posttranslation processing of proglucagon secreted from L-cells in the lower gut. It has two forms: GLP1(7-36), which is a 30-residue amide, and GLP1(7-37), which is a 31-residue glycine-extension peptide. It stimulates insulin secretion in response to the plasma glucose concentration change, and it is considered to have great potential in treating Type 2 diabetes.

The sequence of GLP-1(7-36) is as follows: His-Ala-Glu-Gly-Thr-Phe-Thr-Ser-Asp-Val-Ser-Ser-Tyr-Leu-Glu-Gly-Gln-Ala-Ala-Lys-Glu-Phe-Ile-Ala-Trp-Leu-Val-Lys-Gly-Arg-NH2.

The sequence of GLP-1(7-37) is as follows: His-Ala-Glu-Gly-Thr-Phe-Thr-Ser-Asp-Val-Ser-Ser-Tyr-Leu-Glu-Gly-Gln-Ala-Ala-Lys-Glu-Phe-Ile-Ala-Trp-Leu-Val-Lys-Gly-Arg-Gly-NH2.

The total synthesis of GLP-1(7-36) was reported by Adelhorst et al. (12) in 1994 using the solid-phase peptide synthesis method. The peptide was synthesized on an ABI MED 422 multiple synthesizer. An Na-Fmoc strategy, which was modified according to Gausepohl et al. (13), was used starting from a Rink-resin. The side-chain protections were as follows: Asn, Gln, and His were proctected by Trt groups; Arg by a Pmc group; Asp, Glu, Tyr, Ser, and Thr by t-butyl groups; and Trp and Lys by Boc groups. The peptides were cleaved from the resin and deprotected by a treatment of TFA/triethylsilane/water (92.5:5:2.5) for 120 minutes and precipitated in t-butylmethyl ether and lyophilized from 10% acetic acid. The crude peptides were purified by reverse phase HPLC with Superpak Pep S C2/C18 column, obtaining a purity of >95%.

Glucose-dependent insulinotropic polypeptide (GIP)

Glucose-dependent insulinotropic polypeptide is originally known as gastric inhibitory polypeptide (GIP), which is a 42-residue peptide first isolated by Brown and Dryburgh (14). It is secreted from the duodenum and proximal jejunum in response to food. Two major physiological effects of GIP are inhibition of gastric acid secretion and stimulation of insulin release.

The sequence of porcine GIP is as follows: Tyr-Ala-Glu-Gly-Thr-Phe-Ile-Ser-Asp-Tyr-Ser-Ile-Ala-Met-Asp-Lys-Ile-Arg-Gln-Gln-Asp-Phe-Val-Asn-Trp-Leu-Leu-Ala-Gln-Lys-Gly-Lys-Lys-Ser-Asp-Trp-Lys-His-Asn-Ile-Thr-Gln-OH.

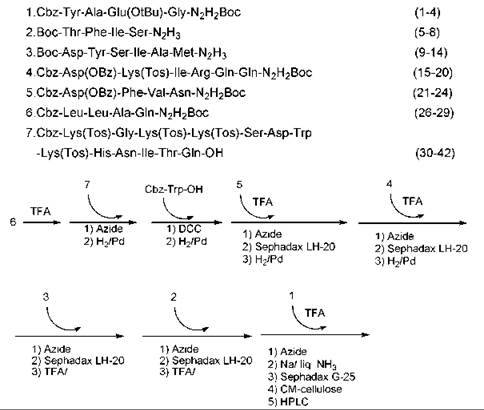

However, the first synthesized “GIP” (15) turned out not to be the real GIP, as the original sequence proposed by Brown and Dryburgh (14) was a 43-residue peptide. Ten years later, Jornvall et al. (16) revised the structure as one glutamine shorter. The first synthesis of the revised GIP structure was done by Mochizuki et al. (17) in 1981 by employing an azide-fragment condensation method in solution. The protected peptide fragments were prepared (Fig. 4), and the Trp residue in position 25 was introduced exceptionally by itself to the 26-42 or 26-43 peptide intermediate by the active ester method. The Cbz and Bn groups were removed by catalytic hydrogenation and the Boc and tBu groups by TFA treatment during the course of fragment condensation. After completing the synthesis, the crude protected peptide was treated with sodium in liquid ammonia to remove N-Cbz and N-Tos groups. The product was first purified by gel filtration on Sephadex G-25, followed by ion-exchange chromatography on CM-cellulose and HPLC with TSJ-Gel LS-420K C-18 column.

Figure 4. Protected fragments of peptide and synthesis scheme for GIP.

Motilin

Motilin is a 22-amino acid peptide first isolated from hog duodenal mucosa by Brown and colleagues in 1972 (18, 19). It was found to be released from endocrine cells of the duodenal-jejunal mucosa to control gastrointestinal muscles by controlling the migrating motor complex.

The sequence of motilin is as follows: Phe-Val-Pro-Ile-Phe-Thr-Tyr-Gly-Glu-Leu-Gln-Arg-Met-Gln-Glu-Lys-Glu-Arg-Asn-Lys-Gly-Gln-OH.

Ikota (20) reported the first solid-phase synthesis of motilin in 1980, and the overall yield was 1.8%. Coy et al. (21) improved the synthesis and got a 10% yield. Coy’s synthesis was carried out on a Beckman model 990 automatic peptide synthesizer using Na-Boc chemistry. Motilin was assembled stepwise on a 1% cross-linked BHA resin with Boc-α-benzyl-Glu as the first amino acid to be incorporated. In this manner, C-terminal Gln could be directly formed on HF cleavage of the final peptide from the resin. The detailed coupling schedule is shown in Table 2 (22). The symmetric anhydride method was used for coupling of all amino acids except for Asn and Gln, which were coupled as active HOBt esters, and DIC was used as the coupling reagent. The side-chain protections were as follows: Arg and His were protected by the Tos groups; Asp, Glu, Ser, and Thr by the Bn groups. Coupling reactions were monitored at each step by using the ninhydrin test. Couplings, which were incomplete after 1 hour, were recoupled by using the appropriate symmetric anhydride preformed at room temperature in DMF.

Table 2. Schedule of events for assembling the peptide BHA resin

|

Step |

Reagentor solvent and operations |

Time (min) |

|

1 |

DCM wash (x 3) |

1 |

|

2 |

33% TFA-DCM |

1 |

|

3 |

33% TFA-DCM |

25 |

|

4 |

DCM wash (x 3) |

1 |

|

5 |

EtOH wash (x 3) |

1 |

|

6 |

CHCl3 wash (x 3) |

1 |

|

7 |

10% Et3N-CHCl3 (x 2) |

5 |

|

8 |

CHCl3 wash (x 3) |

1 |

|

9 |

DCM wash (x 3) |

1 |

|

10 |

Na-Boc-amino acid (3 eq) + DIC (3 eq) in DCM* |

60 |

|

11 |

DCM wash (x 3) |

1 |

|

12 |

EtOH wash (x 3) |

1 |

*Asn and Gln were dissolved in DMF, Na-Boc-Arg(Tos) in 10% DMF-DCM. The extent of couplings was monitored by the ninhydrin test. Recouplings carried out by symmetric anhydride procedure in DMF if necessary.

After the completion of the solid-phase synthesis, 0.25 mmol of peptide-resin was treated with HF (30 mL) that contained 10% anisole for 30 minutes at 0 °C. After rapid removal of HF under a stream of nitrogen, free, deprotected peptide amide was precipitated by addition of ether, and then it was partially purified on Sephadex G-25. Additional purification was done on an octadecylsilyl-silica column (1.5 x 45 cm) by elution with a linear gradient formed from 200 mL each of 15 and 30% 1-propanol in 10% acetic acid at a flow rate of 2 mL/min. Examination of the fractions by TLC and HPLC located the peptide in the 3rd peak (Fig. 5). Fractions were pooled for maximum purity to give 70 mg (10%) of motilin.

Figure 5. Purification of crude synthetic motilin on column of LRP-1 ODS silica. Taken from Coy et al. (21).

Neuropeptide Y (NPY)

NPY is a 36-amino acid peptide amide first isolated from porcine brain by Tatemoto et al. (23, 24) in 1982. It is found distributed in the central nervous system where it is involved in the control of blood pressure and appetite, and also in the peripheral nervous system, where it is a potent vasoconstrictor and presynaptic inhibitor of neurotransmission.

The sequence of porcine NPY is as follows: Tyr-Pro-Ser-Lys-Pro-Asp-Asn-Pro-Gly-Glu-Asp-Ala-Pro-Ala-Glu-Asp-Leu-Ala-Arg-Tyr-Tyr-Ser-Ala-Leu-Arg-His-Tyr-Ile-Asn-Leu-Ile-Thr-Arg-Gln-Arg-Tyr-NH2.

Krstenansky et al. (25) successfully prepared porcine NPY in 1987. It was synthesized by solid-phase techniques with an Applied Biosystems Inc. Model 430-A peptide synthesizer using MBHA resin. All residues were double coupled as the preformed symmetric anhydrides of the Na-Boc amino acid derivatives except for Asn and Gln, which were coupled with the DCC/HOBT methodology (refer to the section on “Corticotropin-releasing factor synthesis” for details). The side-chain protections were as follows: Arg and His were protected by Tos groups; Asp and Glu by cHx groups; Ser and Thr by Bn groups; Lys by a 2,6-Cl-Cbz group; Tyr by a 2-Br-Cbz group. After completing the synthesis, deprotection and the resin cleavage were performed by a treatment with HF that contained 5% anisole for 50 minutes at 0 °C. The HF was removed in vacuo at 0 °C, and the crude peptide was precipitated with ether and extracted with 30% acetic acid. The extract was lyophilized.

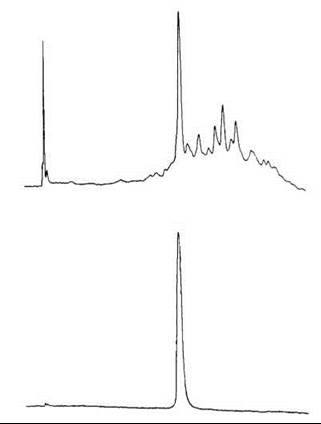

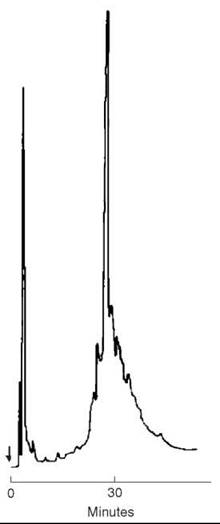

First-round purification was carried out on a 2.6 x 92-cm Sephadex G-15 column at 30 mL/h and 20 minutes per fraction (Fig. 6, top) (25). The fractions that contained the major peak detected by UV at 254 nm were combined and lyophilized. The residue was then purified for the second round by preparative HPLC on a 21.4 x 250 mm Rainin Dynamax C-18 column at 10 mL/min with 34% MeCN in 0.1% TFA. The main peak detected by the UV at 215 nm, and 280 nm was collected and lyophilized leaving 35 mg (3%) final product (Fig. 6, bottom).

Figure 6. HPLC of synthetic porcine NPY. Top: after HF cleavage and Sephadex G-15 chromatography. Bottom: after preparative HPLC purification. Condition: Vydac 218TP54 (4.6 x 250 mm) C-18 column with a linear gradient of 25-50% acetonitrile in 0.1% TFA over 25 minutes at 2 mL/min. Taken from Krstenansky et al. (25).

Peptide tyrosine tyrosine (PYY)

PYY is a 36-amino-acid peptide originally isolated from porcine upper intestine by Tatemoto et al. (26, 27). It contains an N-terminal tyrosine and a C-terminal tyrosine amide and therefore is named peptide YY. It has a high degree of sequence homology (70%) with neuropeptide Y, and it strongly inhibits pancreatic exocrine secretion and jejunal and colonic motility as well as causes vasoconstriction.

The sequence of human PYY is as follows: Tyr-Pro-Ile-Lys-Pro-Glu-Ala-Pro-Gly-Glu-Asp-Ala-Ser-Pro-Glu-Glu-Leu-Asn-Arg-Tyr-Tyr-Ala-Ser-Leu-Arg-His-Tyr-Leu-Asn-Leu-Val-Thr-Arg-Gln-Arg-Tyr-NH2.

Tatemoto et al. (28) also reported a solid-phase synthesis of PYY. Human PYY was prepared manually using Na-Fmoc protection strategy on a 4-aminomethyl-3,5-dimethylphenoxyl resin (PAL resin). The coupling reaction was carried out using a five-fold excess of Na-Fmoc amino acid and DIC in DMF. The α-amino group of the growing peptide was deprotected with 20% piperidine in DMF for 10 minutes. The side-chain protections were as follows: Asp, Glu, Set, Thr, and Tyr were protected by t-Bu groups; Lys by a Boc group; His by a Trt group; Arg by a Mtr group. The peptide was deprotected and cleaved from the resin by a treatment with TFA/thioanisole/ethanedithiol/anisole (90/5/3/2) for 8 hours at room temperature. After filtration, TFA was removed in vacuo, and the peptide was precipitated by ether. The precipitate was redissolved in 0.1 M acetic acid and lyophilized. The crude peptide was purified using a reverse-phase HPLC column (MCI GEL ODS-1HU, 10 x 300 mm, Mitsubishi Kasei, Japan) with a linear gradient system of 0.1% TFA/water and 0.1% TFA/acetonitrile. The synthetic peptide obtained was found to coelute in HPLC with the natural peptide, and the results of amino acid and sequence analyses indicated that it was identical to human PYY.

Secretin

Secretin is a 27-residue peptide amide hormone produced by S cells of the duodenum. The primary effect of secretin is stimulating the release of bicarbonate from liver, pancreas, and duodenal tissues to inhibit gastrin-induced gastric acid release. It also enhances the effects of cholecystokinin and promotes normal growth and maintenance of the pancreas.

The sequence of secretin is as follows: His-Ser-Asp-Gly-Thr-Phe-Thr-Ser-Glu-Leu-Ser-Arg-Leu-Arg-Asp-Ser-Ala-Arg-Leu-Gln-Arg-Leu-Leu-Gln-Gly-Leu-Val-NH2.

Several classic syntheses of secretin have been reported using either fragment condensation or repetitive coupling of single residues (29); one solid-phase synthesis has also been reported (30). However, a peptide-stability problem arose, and it caused difficulty in developing an efficient solid-phase synthesis of the peptide. Coy and Gardner (31) developed a two-stage rapid purification method to avoid traditional long purification routes, and this approach solved potential degradation problem of the peptide.

Coy’s synthesis was carried out on a Beckman model 990 automatic peptide synthesizer (Beckman Instruments, Fullerton, CA) using Na-Boc chemistry. Secretin was assembled stepwise on a 1.0 mmol of 1% cross-linked BHA resin support using the synthesis schedule described in Table 2. The side-chain protections were as follows: Asp, Glu, Ser, and Thr were protected by Bn groups; Arg and His by Tos groups. Each amino acid was successively coupled in the presence of DIC and, in the case of Asn or Gln, 1 equivalent of HOBt was added. Coupling reactions were monitored at each step by using the ninhydrin test. Couplings that were incomplete within 1 hour were recoupled by using the appropriate symmetric anhydride preformed at room temperature in DMF.

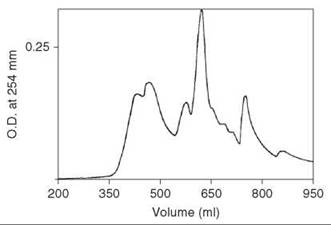

After the completion of the solid-phase synthesis, the peptide resin was treated with HF that contained 10% anisole for 30 minutes at 0 °C. After rapid removal of HF under a stream of nitrogen, free, depretected peptide was precipitated by addition of ether, and it was washed and extracted into 2 M acetic acid. This solution was applied to a column (2.5 x 95 cm) of Sephadex G-25, which was eluted with 2 M acetic acid. Material that emerged just after the void volume as a major peak (254 nm) contained the major component confirmed by TLC. This material was injected onto a column (2.5 x 45 cm) of ODS silica LRP-1 (Whatman) (13-24 pm) and was eluted with a linear gradient of 15 and 35% 1-propanol in 0.1 M ammonium acetate (pH 4) at a flow rate of 5 mL/min and a pressure about 60psi. Fractions were examined by TLC and analytical HPLC, and the partially resolved peak emerging at 375 mL that contained the major component was found identical to a standard sample of secretin (Fig. 7). The peptide was lyophilized to give about 120 mg final product.

Figure 7. Chromatography of crude synthetic secretin eluted on a column (2.5 x 45 cm) of ODS silica LRP-1 (Whatman) (13-24 pm) with a linear gradient of 15 and 35% 1-propanol in 0.1 M ammonium acetate (pH 4) at a flow rate of 5 mL/min and pressure about 60 psi. Taken from Coy et al. (21).

Somatostatin

Somatostatin is a hormone that comprises two peptides, one built of 14 amino acids and the other of 28 amino acids. They are secreted not only by cells of the hypothalamus but also by delta cells of the stomach, intestine, and pancreas. They inhibit the release of numerous gut peptides, like CCK, gastrin, secretin, motilin, GIP, and they also inhibit insulin and glucagon secretion from the pancreas.

The sequence of hypothalamic somatostatin 14 is as follows: Ala-Gly-c(Cys-Lys-Asn-Phe-Phe-Trp-Lys-Thr-Phe-Thr-Ser-Cys)-OH.

The sequence of hypothalamic somatostatin 28 is as follows: Ser-Ala-Asn-Ser-Asn-Pro-Ala-Met-Ala-Pro-Arg-Glu-Arg-Lys-Ala-Gly-c(Cys-Lys-Asn-Phe-Phe-Trp-Lys-Thr-Phe-Thr-Ser-Cys)-OH.

Somatostatin 14 was isolated, characterized, and synthesized by Guillemin’s group in 1973 (32, 33). Several independent studies of the peptide’s synthesis were reported immediately after that (34-37). Among those studies, Rivier reported in detail the first solid-phase synthesis of the peptide in a highly purified form. The protected somatostatin tetradecapeptide was synthesized in a stepwise manner on chloromethylated resin prepared according to Stewart and Young (38). Na-Boc chemistry was used for the synthesis; all amino acids were coupled as symmetric anhydrides using DCC as the coupling reagent except for Asn, which was coupled as Np active ester. The side-chain protections were as follows: Thr and Ser were protected by Bn groups; Lys by a 2-Cl-Cbz group. Na-Boc-Cys(p-OMe-Bn) was used because it is easily removed by HF. Ala and Gly were introduced as a Cbz-protected dipeptide (Cbz-Ala-Gly-OH) to have a reliable internal standard to evaluate the amino-acid analyses. TFA was used for cleavage of the Na-Boc protecting groups, and 1,2-ethanedithiol was added for protection of the Trp residue from oxidation, which is a problem that has long been recognized in solid-phase synthesis. The completion of coupling was monitored by the ninhydrin test. The detailed schemes used for the synthesis are reported in Tables 3 and 4.

Table 3. Schedule for DCC Coupling in Solid-phase Synthesis of Somatostatin-14*

|

Step |

Reagents or solvents and operations |

Time (min) |

|

1 |

DCM wash, 80 mL (x 2) |

3 |

|

2 |

MeOH wash, 30 mL (x 2) |

3 |

|

3 |

DCM wash, 80 mL (x 3) |

3 |

|

4 |

50% TFA + 5% 1,2-ethanedithiol in DCM, 70 mL (x 2) |

10 |

|

5 |

DCM wash, 80 mL (x 2) |

3 |

|

6 |

Et3N 12.5% in DMF, 70 ml (x 2) |

5 |

|

7 |

MeOH wash, 40 mL (x 2) |

2 |

|

8 |

DCM wash, 80 mL (x 3) |

3 |

|

9 |

Boc-amino acid (10 mmol) in 30 mL of DMF (x 1) + DCC (10 mmol) in DMF |

30 |

|

10 |

MeOH wash, 40 mL (x 2) |

3 |

|

11 |

Et3N 12.5% in DMF, 70 ml (x 1) |

3 |

|

12 |

MeOH wash, 30 mL (x 2) |

3 |

|

13 |

DCM wash, 80 mL (x 2) |

3 |

* Aliquots taken for ninhydrin test: if negative, go back to step 1, if positive or slightly positive, go back to steps 9 → 13.

Table 4. Solid-phase synthesis of somatostatina schedule for Na-Boc-Asn-PNP coupling*

|

Step |

Reagents or solvents and operations |

Time (min) |

|

9 |

DMF wash, 60 mL (x 3) |

3 |

|

10 |

BocAsn-PNP (15 mmol) in 20 mL of DMF (x 1) |

800 |

|

11 |

MeOH wash, 30 mL (x 4) |

3 |

|

12 |

Et3N 12.5% in DMF, 30 ml (x 2) |

3 |

|

13 |

MeOH wash, 30 mL (x 2) |

3 |

|

14 |

DCM wash, 80 mL (x 3) |

3 |

*Same as lines 1-8 in Table (1) followed by changes shown. Aliquots taken for ninhydrin test: if negative, go back to step 1, if positive or slightly positive, go back to steps 9 → 13.

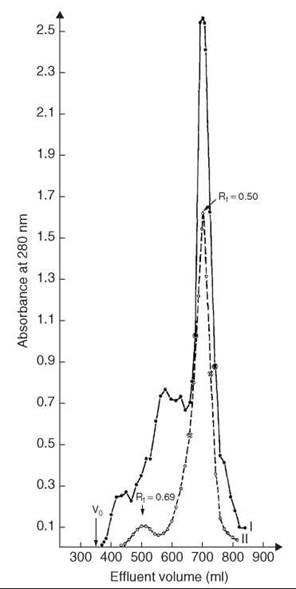

Cleavage and concomitant deprotection of the tetradecapeptide were achieved by HF in presence of anisole. After removing HF in vacuo and work-up, a white fluffy material that accounted for 60% of the calculated yield was obtained. A second HF treatment was applied to the resin, and 25% more of the peptide was obtained. The crude material was subjected to gel filtration. The main peak (Fig. 8, profile I) after lyophilization and routine handling was reapplied on the same column under the same conditions in an attempt to obtain one single symmetrical pattern (Fig. 8, profile II). A total yield of 28% in purified linear somatostatin was obtained.

Figure 8. Gel filtration of crude and purified synthetic reduced somatostatin. Column: 2.5 x 200 cm Sephadex G-25F, 2 N AcOH, 10-2 M β-mercaptoethanol. V0 = hold-up volume: profile I(•) 1.25 g crude, yield 670-740 mL, 500 mg, 40%; profile II (bharathi) 500 mg from I, yield 660-728 mL, 350 mg, 28%. Taken from Rivier et al. (37).

Synthesis of somatostatin-28 has been reported by Nicolas et al. (39) in 1986. Na-Boc protected amino acids were assembled on chloromethyl/1% divinylbenzene resin by using solid-phase peptide synthesis techniques. The first amino acid was loaded by mixing the resin and Na-Boc-Cys(3,4-dimethylbenzyl)-OH in DMF for 18 hours at 50 °C in the presence of KI. The side-chain protections were as follows: Asp, Thr, Ser, and Glu were protected by Bn groups; Lys by a 2-Cl-Cbz group; Tyr by a 2-Br-Cbz group; Arp by a Tos group; Cys by a 3,4-dimethyl-Bn group; Trp by a For group. The coupling was done using the symmetric anhydride method according to the protocol shown in Table 5 (40), except Asn was first coupled for 15 hours as its p-nitrophenyl ester in DMF and then by the use of HOBt as reported (41). After the coupling was completed, the peptide-resin was subjected to steps 1-10, washed with EtOH, and dried. The cleavage of the peptide was done by treating the peptide-resin with liquid HF in the presence of anisole for 30 minutes at -20 °C and then 60 minutes at 0 °C. After removal of HF by a stream of nitrogen, the residue was stirred in EtOAc, and the solid material was filtered off. The filtrate was purified on a Sephadex G-25 column (2.6 cm x 100 cm) equilibrated and run with degassed 10% AcOH saturated with nitrogen. The main peak was lyophilized, which yielded 565 mg product. Deformylation and formation of the disulfide bond were carried out by dissolving 100 mg material in water (25 mL) that contained 75 pL hydrazine and taken to pH 11.5 with 1 M NaOH. After 2 minutes, the solution was diluted to 1000 mL with distilled water, adjusted to pH 8 with glacial acetic acid, and allowed to stand at 24 °C. After 22 hours, less than 1% free thiols remained as assessed by the Ellman’s method (42).

After lyophilization, the material was dissolved in 5 mL of 10% AcOH and filtered through a Sephadex G-50F column (2.5 cm x 91cm) in 10% AcOH. Isolation of material in the major peak gave 61 mg. This material was subjected to chromatography on CM-cellulose in a 1.5 cm x 35-cm column initially equilibrated with 10 mM NH4OAc, pH 4.2. A gradient was applied through a 200 mL constant volume mixing chamber that contained the initial buffer by introducing 0.45 M NH4OAc, pH 7. Material in the major peak was isolated to gave 16.5 mg (a 6% overall yield) of somatostatin-28.

Substance P

Substance P is an 11-amino-acid peptide amide hormone discovered by von Euler and Gaddum in 1931 (43) from certain tissue extracts, especially from intestinal plain muscles and brains of horses. It is involved in the transmission of pain impulses from peripheral receptors to the central nervous system. It is also involved in the vomit reflex, stimulates salivary secretions, and induces vasodilation. Antagonists seem to have antidepressant properties.

The sequence of substance P is as follows: Arg-Pro-Lys-Pro-Gln-Gln-Phe-Phe-Gly-Leu-Met-NH2.

This peptide was synthesized by Fisher et al. (44) in 1974 employing the solid-phase technique using Na-Boc chemistry. BHA-type resin was used for the synthesis on a Beckman Model 990 solid-phase peptide synthesizer. Dried BHA-resin hydrochloride was neutralized with triethylamine and stirred overnight with an excess of Na-Boc-Met and DCI in DCM. The remaining unreacted amino groups of the resin were acetylated with a mixture of Ac2O and triethylamine in DMF overnight. Amino-acid analysis of the resin, after hydrolysis in 6 N HCl-propionic acid (1:1), gave a value of 0.2 mM/g of Met. The side-chain protections were as follows: Lys was protected by a Cbz group; Arg by a Tos group. A 2.5-fold excess of each amino acid was used for coupling with a reaction time of 6 hours except for Gln, which was incorporated as a fivefold excess of its Np active ester with an 11-hour coupling time. Dry DCM was used as the coupling solvent except for Arg and Gln, which required purified DMF. Na-Boc deprotection was accomplished by 50% TFA in DCM with neutralization by 10% Et3N in DCM. The completion of coupling was monitored by the ninhydrin test, and recoupling was done when needed (refer to the sections on “Motilin synthesis” and “Secretin synthesis” for details). Cleavage of the peptide from the resin, with simultaneous removal of the protecting groups and formation of the carboxyl terminal amide, was affected with 20 mL of dry HF in the presence of 2mL of anisole for 1 hour at 0 °C. After removal of the excess HF in vacuo, the resin was washed with EtOAc to remove anisole, followed by 0.5 N HOAc to extract the peptide; 424 mg crude product was obtained and lyophilized.

Purification was done by gel filtration on a 102 x 2.5 cm column of Bio-Gel P2 eluted with 1.3% AcOH, with detection of the peptide peaks by UV at 256 nm. The main fraction (253 mg) was partitioned on a 100 x 1.5 cm column of Sephadex G-25 eluted with the system 0.1% AcOH-n-BuOH-Pyr (11:5:3) with detection of the peptide peaks by the Folin-Lowry procedure (45) at 700 nm, giving 90 mg (16.7%) of pure substance P.

Na-Fmoc synthesis of substance P also has been reported (46).

Table 5. Schedule for coupling in solid-phase synthesis of somatostatin-28

|

Step |

Reagents or solvents and operations |

Time (min) |

|

1 |

DCM wash, 15 mL (x 3) |

3 |

|

2 |

55% TFA-DCM wash, 15 mL (x 1) |

1 |

|

3 |

55% TFA-DCM wash, 15 mL (x 1) |

15 |

|

4 |

DCM wash, 15 mL (x 2) |

2 |

|

5 |

25% Dioxane-DCM wash, 15 mL (x 2) |

2 |

|

6 |

DCM wash, 15 mL (x 2) |

2 |

|

7 |

5% DIEA-DCM wash, 15 mL (x 2) |

2 |

|

8 |

DCM wash, 15 mL (x 2) |

2 |

|

9 |

5% DIEA-DCM wash, 15 mL (x 2) |

2 |

|

10 |

DCM wash, 15 mL (x 6) |

6 |

|

11 |

Symmetric anhydride of Boc-amino acid (1.5 mmole) in DCM 13 mL |

60* |

|

12 |

DCM wash, 15 mL (x 3) |

3 |

|

13 |

5% DIEA-DCM wash, 15 mL (x 2) |

2 |

|

14 |

DCM wash, 15 mL (x 6) |

6 |

|

15 |

Symmetric anhydride of Boc-amino acid (1.5 mmole) in DCM 13 mL |

60* |

|

16 |

DCM wash, 15 mL (x 3) |

3 |

|

17 |

33% EtOH-DCM wash, 15 mL (x 3) |

3 |

* In the case of Na-Boc-Val, -Leu, -Thr, 90 minutes of reaction time.

Vasoactive intestinal peptide (VIP)

VIP is a 28-amino-acid residue peptide amide isolated in 1970 by Said and Mutt in the course of the purification of secretin from porcine duodenum (47). It was characterized 2 years later as a highly basic peptide related to gut peptides. It inhibits acid and pepsin secretion, acts as a neurotransmitter in peripheral autonomic nervous system, and increases secretion of water and electrolytes from pancreas and gut.

The sequence of porcine VIP is as follows: His-Ser-Asp-Ala-Val-Phe-Thr-Asp-Asn-Tyr-Thr-Arg-Leu-Arg-Lys-Gln-Met-Ala-Val-Lys-Lys-Tyr-Leu-Asn-Ser-Ile-Leu-Asn-NH2.

Bodanszky reported the first synthesis of VIP using solution- phase peptide synthesis (48). Several other syntheses, both solid-phase and solution-phase, also have been reported (49-52). Among these syntheses, Fournier’s study is representative. Na-Boc solid-phase synthesis techniques were used. Peptide syntheses were carried out with a Vega peptide synthesizer (Vega Biotech., Tucson, AZ) in the automatic mode following operations as described (53) (similar to Tables 3 and 4) except that 1% D,L-methionine was used in TFA instead of 5% thioanisole. The first amino acid was loaded to the BHA resin (0.21 meq/g) via the DCC-HOBt procedure after neutralization of the resin with 25% triethylamine-DCM. The remaining amino acids were coupled as symmetric anhydrides and were prepared using a 6-molar excess of Na-Boc-amino acid and DCC. Nitrogen is bubbled through the suspension to eliminate air and moisture in the mixing reservoir. For Asn and Gln, couplings were achieved by the DCC-HOBt method. The side-chain protections were as follows: Ser, Thr, and Asp were protected by Bn groups; His by a Boc group; Tyr by a 2-Br-Cbz; Arg by a Tos group; Lys by a 2-Cl-Cbz group. Every coupling was monitored for completion using the ninhydrin test (refer to the sections on “Motilin synthesis” and “Secretin synthesis” for details). Excess amino groups were acetylated when the test showed slightly positive results (~1%). After the last amino acid was introduced, the cleavage and deprotection were executed in the Kel-F reaction vessels of a liquid HF apparatus. HF (8-10 mL/g) and a 5-molar excess D,L-methionine were added to the vessel that already contains anisole. The reaction proceeded for 30 minutes at -20 °C and for another 30 minutes at 0 °C. The HF was rapidly evaporated in vacuo, and the resin was washed with ether. The crude peptide was extracted with 30% acetic acid (~200 mL), and the solution was lyophilized.

The crude peptide was dissolved in a minimal volume of 0.005-M ammonium acetate buffer at pH 6.0, and then it was applied to a column of Whatman CM-23 ion exchange resin equilibrated with the same buffer. The peptide was eluted with a pH and ionic gradient of adding 0.20 M pH 7.5 ammonium acetate buffer to the initial one at a flow rate of 700 mL/h. The elution was monitored by UV at 280 nm. Fractions (12 mL) that corresponded to the major peak were collected and lyophilized twice to eliminate the volatile salt. A second chromatographic step on CM-23 resin was achieved with a pH and ionic gradient obtained by the addition of 0.12 M pH 7.5 to 0.005 M pH 5.9 at a flow rate of 700-1000 mL/h. In the third purification step, the semi-purified VIP was injected on a partition chromatography column packed with Sephadex G-50 resin and equilibrated with the solvent system 1-butanol, acetic acid, and 0.5%-pyridine (5:10:3). The flow rate was set to 20 mL/h, and 5-mL fractions were collected. Final purification (Fig. 9) was carried out on HPLC using a semipreparative Waters pBondapak C-18 column under isocratic conditions: methanol ammonium acetate 0.10 M, pH 5.2 (70:30). The flow rate was adjusted to 1.2 mL/min, and the peptide was detected at 246 nm by UV. Two-hundred fifty μL of 40 mg/mL peptide solution were injected. The main peak was collected and lyophilized, which gave an overall yield of 4%.

Figure 9. HPLC purification of partially purified VIP. Taken from Fournier et al. (52).

Corticotropin-releasing factor (CRF or CRH)

CRF is a 41-amino-acid peptide first isolated from ovine hypothalamic extracts and characterized by Vale et al. (54) in 1981. It has a high potency for stimulating the secretion of corticotropin-like and P-endorphin-like immunoactive substances.

The sequence of ovine CRF is as follows: Ser-Gln-Glu-Pro-Pro-Ile-Ser-Leu-Asp-Leu-Thr-Phe-His-Leu-Leu-Arg-Glu-Val-Leu-Glu-Met-Thr-Lys-Ala-Asp-Gln-Leu-Ala-Gln-Gln-Ala-His-Ser-Asn-Arg-Lys-Leu-Leu-Asp-Ile-Ala-NH2.

Vale et al. (54) also synthesized the peptide, but they did not provide details of the synthesis. In 1982, Sueiras-Diaz and Coy (55) published the first detailed synthesis of ovine CRF using Na-Boc solid-phase synthesis techniques. The amino acids were assembled on a 1% cross-linked BHA resin (2.1 g; 0.49-mmol amino groups/g) using a Beckman 990 automatic synthesizer (Beckman Instruments, Fullerton, CA). The symmetric anhydride procedure in DMF was used for the coupling of amino acids, and DIC was the coupling reagent. In the case of Asn and Gln, they were coupled with an equimolar amount of HOBt. Na-Boc protection was removed at each stage by two treatments with 33% TFA in DCM for 1 minute and 25 minutes. Reactive side-chains protections were as follows: Ser and Thr were protected by Bn groups; Lys by a 2-Cl-Cbz group; His and Arg by Tos groups; Asp and Glu by 4-Cl-Bn groups. Coupling reactions were monitored at each step by the ninhydrin test and repeated if incomplete after 60 minutes. If free amino groups persisted, they were acetylated with acetylimidazole (5% in DCM, 50 minutes). (Refer to the section on “Motilin synthesis” and “Secretin synthesis” for details.)

The completed, protected peptide resin, with its N-terminal Boc group removed to avoid alkylation of Met during HF cleavage steps, was deprotected and liberated from the resin support (1 mM) by a treatment with 60 mL anhydrous HF that contained 10% anisole for 1 hour at 0 °C. After removing the HF under nitrogen, the peptide was precipitated with ether, then filtered and extracted with 50% acetic acid. After reduction in volume, the solution was applied directly onto a column (2.5 x 95 cm) of Sephadex G-50 and eluted with 2 M AcOH. Fractions were collected and aliquots were examined by TLC in the solvent system of 1-butanol:pyridine:acetic acid:water (15:10:3:12). The peptide was visualized with ninhydrin, and then pooled and lyophilized to a constant weight of 3.92 g. This material was examined by HPLC on a column (0.4 x 25 cm) of Synchropack RP-18 (10 μm, 300 A pore size) using a gradient of 25-35% isopropanol in 0.1% TFA over 30 minutes. Absorption at 215 nm revealed a major peak (Fig. 10) that contained contaminants at its leading and trailing edges.

Figure 10. HPLC of 100 μg of crude CRF after Sephadex chromatography on C-18 Synchropack (10 pm, 300 A°)(0.4 x 25 cm) using a gradient of 25-35% isopropanol in 0.1% TFA over 30 minutes. Flow rate 1 mL/min., absorption at 215 nm. Taken from Sueiras-Diaz et al. (55).

Part of this material (340 mg) was purified even more by reversed-phase medium-pressure liquid chromatography procedure using a column (2.5 x 45 cm) of Whatman LRP-I (C-l8-bonded silica gel, 13-24 pm) eluted with a gradient from 15-60% acetonitrile in 0.1% TFA. Aliquots from the main peak were pooled and lyophilized to give 75 mg of almost pure peptide, which counted a 18.5% yield based on resin incorporation. The final purification was achieved by a preparative RP-HPLC procedure using a C-18, 10 μm, 300A Synchropack column (1 x 25 cm), loaded with 11.7 mg and eluted with a gradient of 23-36% isopropanol in 0.1% TFA developed over 1 h. Fractions were collected manually and aliquots were checked by HPLC. Those fractions judged pure, favoring purity rather than quantity, were then pooled, concentrated in vacuo and lyophilized to a constant weight of 4.55 mg, which gave a 7% overall yield.

Gonadotropin-releasing factor (GnRF or GnRH)

GnRH, which was originally known as luteinizing hormone (LH) and follicle-stimulating hormone (FSH) releasing hormone, is a 10-residue polypeptide isolated from porcine hypothalami by Schally et al. (56) in 1971. It acts on the gonadotrope to control the release of LH and FSH.

The sequence of porcine GnRH is as follows: (pyro)Glu-His-Trp-Ser-Tyr-Gly-Leu-Arg-Pro-Gly-NH2.

Matsuo et al. (57) also have prepared this peptide via solid-phase peptide synthesis. The protected decapeptide resin ester (Na-Boc-Gln-His-Trp-Ser(OBzl)-Tyr(OBzl)-Gly-Leu-Arg (NO2)-Pro-Gly-resin ester) that corresponds to the amino acid sequence of LH-RH/FSH-RH was synthesized using Na-Boc chemistry by the method described by Stewart and Young (38), which starts with Na-Boc-Gly-resin ester (1.0 g: 0.35 mmole). The side-chain protections were as follows: Ser and Tyr were protected by Bn groups, Gln by a Np group, Arg by a NO2 group. Coupling was achieved with DCC with the single exception that Gln was coupled by means of its p-nitrophenyl ester. Stepwise synthesis was carried out in the DCM and/or DMF using a glass shaker at room temperature. The removal of the Na-Boc groups in the first seven steps was performed by treatment with 50% TFA in DCM for 20 minutes. After the incorporation of the Trp residue, 1 N HCI in acetic acid that contained 1% 2-mercaptoethanol was used for the removal of the Na-Boc group as described by Marshall (58). The neutralization was carried out by shaking with 10% triethylamine in CHCl3. In every DCC coupling step, 4 equivalents of Na-Boc-amino acid (4 x 0.35 mmole) for every equivalent of the starting glycine resin ester was used in the presence of 4 equivalents of DCC for 5 hours. An additional reaction with the same reagents was performed for another 5 hours. For the incorporation of His residue, 5 equivalents of Na-Boc-His were used, and the same reaction was carried out twice as above. Nitrophenyl ester coupling of Na-Boc-Gln was performed with 10 equivalents of the active ester for 5 hours, followed by an additional treatment for 5 hours in the presence of 5 equivalents of imidazole. The yield of the protected decapeptide resin ester was 1.38 g (about 78% based on dry weight and amino acid analysis).

To achieve cyclization of N-terminal glutaminyl group on the resin to the pyroglutamyl-ring after removal of Na-Boc group, the Na-Boc-glutaminyl-peptide resin ester was treated with 1 N HCI in acetic acid that contained 1% of 2-mercaptoethanol for 1 hour at room temperature. The peptide was cleaved by stirring in 20 mL of absolute methanol saturated with ammonia for 3 days at room temperature. After filtration, evaporation of the methanolic filtrate yielded 368 mg of the corresponding amide as a yellow semi-solid material. All protecting groups were removed by treatment with liquid HF in the presence of 2 mL of anisole for 1 hour at 0 °C.

After evaporation, the residual material was dissolved in 5 mL of acetic acid that contained 1% of 2-mercaptoethanol and heated in an evacuated sealed tube at 100 °C for 10 minutes for the completion of cyclization to the pyroglutamyl-group (59, 60). After addition of 50 mL of water, followed by lyophilization, the residual solid was dissolved in 0.2 N acetic acid and lyophilized. The resulting slightly yellow solid was purified by the counter-current distribution (CCD) in the solvent system of 0.1% acetic acid:butanol:pyridine (11:5:3) for 400 transfers. Lyophilization of fractions No. 282-343 (K = 2.0) after CCD afforded 153 mg of purified LH-RH as a white fluffy solid, which showed about 25% of the biological activity of natural porcine GnRH. On paper-chromatography (Whatman No. 1) in 1-butanol:pyridine:acetic acid:water (15:10:3:12), this material showed two spots, positive to Pauly’s reagent and negative to ninhydrin, with Rf = 0.67 and 0.79, respectively. Paper-electrophoresis (pH 6.4 pyridine acetate, 2,500 volts, 1 hour) also exhibited two spots with RLVP2 0.95 and 0.76, respectively. The main spot with Rf = 0.67 and RLVP2 = 0.95 was found to be identical with natural porcine LH-RH. Additional purification of 9-mg portions of the CCD-purified material was carried out on a column of carboxymethylcellulose (1 x 60 cm) using 0.1 M ammonium acetate pH 7.0 for elution. This process yielded 2 mg of essentially pure synthetic GnRH, which was identical chromatographically and electrophoretically with natural porcine GnRH.

Growth hormone releasing factor (GRF or GRH)

GRF has been isolated and characterized from a human tumor of the pancreas (61) as well as from rat (62), porcine (63), bovine (64), caprine (65), ovine (65), and human (65) hypothalamus stalk-median eminence. It is a 40-44-amino-acid peptide hormone produced in the arcuate nucleus of the hypothalamus and released from neurosecretory nerve terminals of these arcuate neurons, and it is carried by the hypothalamo-hypophysial portal circulation to the anterior pituitary gland where it stimulates growth hormone (GH) secretion (66).

The sequence of human GRH is as follows: Tyr-Ala-Asp-Ala-Ile-Phe-Thr-Asn-Ser-Tyr-Arg-Lys-Val-Leu-Gly-Gln-Leu-Ser-Ala-Arg-Lys-Leu-Leu-Gln-Asp-Ile-Met-Ser-Arg-Gln-Gln-Gly-Glu-Ser-Asn-Gln-Glu-Arg-Gly-Ala-Arg-Ala-Arg-Leu-NH2.

Ling et al. (65) have described the synthesis of hGRH in 1984 after they isolated and characterized the peptide from human hypothalamic tissues. The peptide was prepared by solid-phase methodology on a Beckman model 990 peptide synthesizer (Beckman Instruments, Fullerton, CA) using Na-Boc chemistry. The MBHA resin (6 g, 0.6 mmol/g) was used, and the side-chain protections were as follows: Ser, Glu, Asp, and Thr were protected by Bn groups; Arg by a Tos group; Lys by a 2-Cl-Cbz group; Tyr by a 2,6-Cl-Bn group. The C-terminal amino acid was loaded to the MBHA resin using the symmetric anhydride method, and DCC was the coupling reagent. The subsequent amino acids were coupled according to the schedule in Table 6.

After the last amino acid had been incorporated, the Na-Boc protecting groups were removed before 1 g of the peptide-resin conjugate was treated with a mixture of 14 mL of HF, 1.5 mL of anisole, and 0.25 mL of methylethyl sulfide at -20 °C for 0.5 hour and at 0 °C for 0.5 hour. The HF was removed in vacuo at 0 °C, and the resulting peptide and resin mixture was washed twice with ether and twice with CHCl3 and ether alternately. The peptide was extracted five times with 2 M CH3COOH, and the extract was lyophilized.

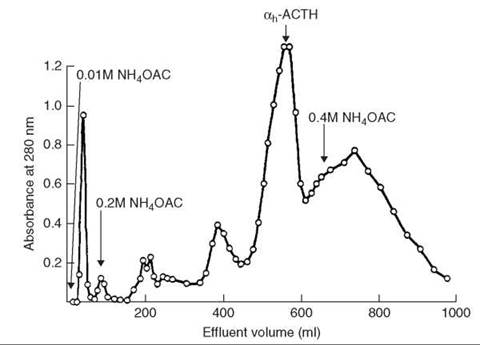

The first purification was done by loading the lyophilized product on a column of Sephadex G-50 developed in 30% CH3COOH to remove the truncated fragments and salt. The next step of purification was by CM-32 carboxymethylcellulose cation-exchange chromatography developed with a gradient generated by adding 2.5 volumes of 0.4 M NH4OAc at pH 6.5 to 1 volume of 0.01 M NH4OAc at pH 4.5. Final purification was achieved by partition chromatography on Sephadex G-50 using the solvent system 1-butanol:ethanol:pyridine:0.2 M CH3COOH (4:1:1:7). The chromatographic fractions were monitored by UV at 280 nm and TLC on 0.25-mm-thick precoated silica gel 60 plates with the solvent system 1-butanol:pyridine:CH3COOH: water (6:6:12:4.8), and the spots were detected with ninhydrin spray. Four-hundred twenty-six milligrams of hGRF was obtained after final purification with an overall yield of 2.3%.

Table 6. Schedule of events for assembling the peptide p-MBHA resin

|

Step |

Reagents or solvents and operations |

Time (min) |

|

1 |

DCM wash (x 2) |

1 |

|

2 |

55% TFA/5% 1,2-ethanedithiol in DCM wash, (x 1) |

0.5 |

|

3 |

Deprotect with 55% TFA/5% 1,2-ethanedithiol in DCM |

20 |

|

4 |

DCM wash, (x 3) |

1.5 |

|

5 |

CH3OH wash, (x 2) |

1 |

|

6 |

10% triethylamine in DCM wash, (x 2) |

1 |

|

7 |

CH3OH wash, (x 2) |

1 |

|

8 |

Repeat step 6, 7 |

|

|

9 |

DCM wash (x 2) |

1 |

|

10 |

Couple with symmetric anhydride* of Boc-amino acid (1 mmole/g of resin) in DCM, Leu, Arg Asn and Gln were coupled in 30% DMF in DCM** |

120 |

|

11 |

DCM wash, (x 1) |

0.5 |

|

12 |

50% DMF-DCM wash, (x 2) |

1 |

|

13 |

10% triethylamine in DCM wash |

0.5 |

|

14 |

CH3OH wash, (x 2) |

1 |

|

15 |

DCM wash, (x 2) |

1 |

|

16 |

Acetylate unreacted N “-amino group with 25% acetic anhydride in DCM |

20 |

|

17 |

DCM wash, (x 2) |

1 |

|

18 |

CH3OH wash, (x 2) |

1 |

* The symmetric anhydride was formed with one equivalent amount of DCC.

**In the cases of Asn and Gln, a 1.2 equivalents of HOBt were included.

Thyrotropin-releasing factor

TRF was isolated from porcine hypothalamus by Schally et al. (67, 68) and from ovine hypothalamus by Guillemin et al. (69) It is a tripeptide amide with the structure of pyroGlu-His-Pro-NH2. Classic synthesis of the peptide has been reported in 1970 (70); solid-phase synthesis was envisaged 1 year later, and Rivaille et al. claimed they successfully prepared the target with a better yield (71). Na-Boc chemistry was used in the synthesis, and Na-Boc was introduced into the amino acid by reacting amino acids with Boc-azide at a constant basic pH. The His side chain was protected with an o,p -dinitrophenyl group. Protected His was coupled to the proline linked on the chloromethylresin by the symmetric anhydride method using DCC (refer to the sections on “Somatostatin synthesis” and “Angiotensin II synthesis” for details). The glutamyl residue was introduced in two ways: 1) Na-Boc-pyroglutamic acid was condensed in the presence of DCC and 2) Na-Boc-glutamine dinitrophenylester was reacted with the dipeptide linked to the resin in DMF. The tripeptide was split from the resin by aminolysis, the imidazole protecting group was removed by thiolysis at pH = 8 (72), and the glutamine converted into pyroglutamic acid by boiling acetic acid (73).

The tripeptide was purified by Sephadex G10 filtration followed by silica-gel chromatography. The pure material did not react with ninhydrin because of the presence of N -terminal py- roglutamic acid. After silica-gel thin layer chromatography in several solvent systems, the product gave a single spot when detected with Pauly’s reagent with overall yield of 73%.

Liver peptide hormones

Angiotensin II

Angiotensin II is an octapeptide derived from biologically inactive decapeptide angiotensin I, which comes from angiotensino- gen through the cleavage by the kidney enzyme renin. It is responsible for essential hypertension through stimulated synthesis and for the release of aldosterone from adrenal cells.

The sequence of horse Angiotensin II is as follows: Asp-Arg-Val-Tyr-Ile-His-Pro-Phe-OH.

Several syntheses of the peptide have been reported by solution methods (74-76). After the introduction of solid-phase peptide synthesis, Marshall and Merrifield conducted the first study of the synthesis of the peptide by using the new technique (77). Na-Boc chemistry was used, and Merrifield resin was selected as the solid support. The side chain protections were as follows: His, Arg, and Asp were protected by Bn groups; Arg by a NO2 group. The Phe was esterified onto the resin in ethanol with the presence of 1 equivalent of triethylamine. The symmetric anhydride method was used for the coupling of the amino acids, and DCC was the coupling reagent. The following cycle of reactions was used to introduce each new residue (Table 7):

Table 7. Scheme of peptide assembling for angiotensin II

|

Step |

Reagents or solvents and operations |

Time (min) |

|

1 |

Glacial acetic acid wash (x 3) |

1 |

|

2 |

Deprotect with 1 N HCl in glacial acetic acid |

30 |

|

3 |

Glacial acetic acid wash (x 3) |

1 |

|

4 |

C2H5OH wash, (x 3) |

1 |

|

5 |

DMF wash, (x 3) |

1 |

|

6 |

Neutralize the HCl with 3 mL of triethylamine in DMF |

10 |

|

7 |

DMF wash, (x 3) |

1 |

|

8 |

DCM wash, (x 3) |

1 |

|

9 |

Add 3.83 mmol of the appropriate BOC amino acid in 20 mL of DCM and allowed to mix |

10 |

|

10 |

Add 3.83 mmol of DCC to couple* |

120 |

|

11 |

DCM wash, (x 3) |

1 |

|

12 |

C2H5OH wash, (x 3) |

1 |

* For the im-benzyl-L-His and nitro-L-arginine cycles, step 8 was deleted, and DMF was substituted for DCM in steps 9-11.

Amino acid analysis showed the average value of the eight amino acid residues to be 0.13 mmol/g of peptide resin or 0.16 mmol/g of unsubstituted copolymer. Removing the protecting groups was achieved by suspending the peptide resin in 20 mL anhydrous TFA and bubbling a slow stream of HBr through the fritted disk of the reaction vessel at 25 °C. The suspension was filtered, and the resin was washed 3 times with 10 mL portions of TFA. The filtrates were evaporated in vacuo. The product was redissolved in TFA and re-evaporated. The syrupy product was then dissolved in acetic acid and lyophilized to give 1.47 g.

Purification of the peptide was done by countercurrent distribution method. A 300-mg portion of the crude octapeptide was purified by 100 transfers in a 1-butanol:acetic acid:water (4:1:5) system. Over 80% of the Sakaguchi-positive material was located in one peak which matched closely a theoretical curve with distribution constant, k = 0.30. The material in the peak was collected and the organic phase was removed by evaporation. The residual aqueous phase was removed by lyophilization; 193 mg of product was obtained, which was equivalent to a yield of 56%.

Pancreatic peptide hormones

Amylin

Amylin is a 37-residue peptide hormone first discovered independently by two research groups in 1987 (78, 79). Amylin is secreted by pancreatic P-cells at the same time as insulin (in a roughly 100:1 ratio), and it is the major component of diabetes-associated islet amyloid deposits. It inhibits basal and insulin-stimulated glucose uptake as well as glycogen synthesis by soleus muscles (80). Thus, amylin is also known as a diabetes-associated peptide.

The sequence of human amylin is as follows: Lys-c(Cys-Asn-Thr-Ala-Thr-Cys)-Ala-Thr-Gln-Arg-Leu-Ala-Asn-Phe-Leu-Val-His-Ser-Ser-Asn-Asn-Phe-Gly-Ala-Ile-Leu-Ser-Ser-Thr-Asn-Val-Gly-Ser-Asn-Thr-Tyr-NH2.

One solid-phase synthesis of amylin has been reported in 1991 by Balasubramaniam et al. (81). Standard Na-Boc chemistry was used for the synthesis, and MBHA resin was selected as the solid support. The coupling was done by using the symmetric anhydride method except for Arg, Asn, and Gln, which were coupled as their HOBt esters (refer to the section on “Corticotropin-releasing factor synthesis” for details). After completing the chain elongation, the peptide was cleaved from the resin using HF at 0 °C. The residue was then oxidized with K3Fe(CN)6 to form the disulfide bond, followed by purification on semipreparative reversed phase column. The overall yield of the synthesis was between 10-20%.

Glucagon

Glucagon is a 29-residue polypeptide secreted by pancreas α-cells. It increases lipid mobilization and glycogenolysis to increase blood glucose levels. It was first discovered by Kimball and Murlin in 1923 (82) when studying pancreatic extracts, but the sequence was not determined until 1957 (83).

The sequence of mammalian glucagons is as follows: His-Ser-Gln-Gly-Thr-Phe-Thr-Ser-Asp-Tyr-Ser-Lys-Tyr-Leu-Asp-Ser-Arg-Arg-Ala-Gln-Asp-Phe-Val-Gln-Trp-Leu-Met-Asn-Thr-OH.

Early attempts to synthesize glucagons proved to be difficult because of the unusual structure, and successful examples were not reported until Wunsch’s classic solution-phase synthesis (84). Mojsov and Merrifield (85) reported the first stepwise solid-phase synthesis of glucagon in 1981, in which they used biphenylisopropyloxycarboxyl amino-acid derivatives and t-Bu based side-chain protections, which were unstable. They improved that to Na-Boc strategy and benzyl-based side chain protections by using their newly developed PAM resin in 1984, which gave a rapid, convenient synthesis (86). The aminomethyl-resin was prepared according to Mitchell et al. (87, 88). The first amino acid Thr was loaded to the resin through 2 steps: 1) Na-Boc-Thr(Bzl)-OH was treated with powdered KF2H2O and [4-(bromomethyl) phenyl]acetic acid phenacyl ester to produce Na-Boc-Thr(Bzl)-OCH2C6H4CH2COOH and 2) the product was then dissolved in DCM and allowed to couple with aminomethyl-resin at the presence of 1 equivalent of DCC, and unreacted amino groups were blocked by acetylation. The peptide chain was then elongated by the symmetric anhydride coupling method. In all, 8 eq. of amino acid and 4 eq. of DCC were used for each coupling, except for Leu and Gly in 1.6 eq and 1.2 eq., respectively. Asn and Gln were coupled with presence of HOBt; Arg at positions 17 and 18 were coupled twice each. The side-chain protections were as follows: Ser and Thr were protected by Bn groups; His and Arg by Tos groups; Asp by a cHx group; Tyr by a Br-Cbz group; Lys by a Cl-Cbz group; Trp by a For group. One synthetic cycle consisted of the following steps: 1) DCM wash, 1 minute, x 3; 2) deprotection with 50% TFA/ DCM wash, 1 minute prewash + 20 minutes; 3) DCM wash, 1 minute, x 6; 4) neutralization with 5% iPr2EtN/DCM wash, 1 minute, x 3; 5) DCM wash, 1 minute, x 6; 6) performed symmetric anhydride coupling in DCM (4 eq.), 60 minutes; 7) DCM wash, 1 minute, x 6; 8) neutralization with 5% iPr2EtN/DCM wash, 1 minute, x 3; 9) DCM wash, 1 minute, x 6; and 10) repeat steps 6) and 7). After the completion of the peptide assemblies, the final deprotection and cleavage of the peptide was done in a Teflon vessel using the HF procedure (80). The crude peptide was then purified by preparative HPLC using C-18 column, the eluant from the major peak was collected and desalted on Sephadex G-10, obtaining pure synthetic glucagon with 48% overall yield.

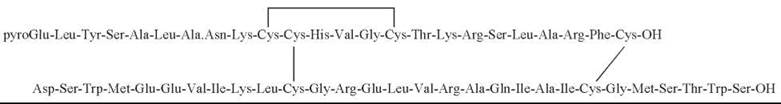

Insulin

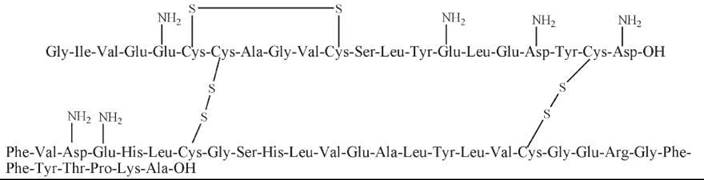

Insulin is a polypeptide hormone produced by p-cells of the pancreas; it contains two disulfide bonded peptide chains: an A chain of 21 residues and an intra-disulfide bridge and a B chain of 30 amino acids. Insulin is well known for regulating carbohydrate metabolism as well as increasing glucose uptake and utilization.

The structure of insulin is shown in Fig. 11. Insulin became one of the most demanded drugs after finding its power to treat Type 1 diabetes in the 1920s. However, it was thought almost impossible to be chemically synthesized at that time after the structure was elucidated by Sanger in 1955 because it involved three disulfide bridges, complicated higher-level structures, and so on. But these complications did not stop it from becoming one of the hottest targets for synthetic chemists. Several independent syntheses of insulin have been reported in the 1960s (89-91) using classic peptide-synthesis methods, which usually required several months to finish, and yields were low. Merrifield et al. (92) reported a fast and efficient synthesis later on by employing solid-phase peptide synthesis technique that only took several days with good yields. Na-Boc chemistry was used for the synthesis. The assembling of the fully protected insulin B chain started with 1.9 mmol of Na-Boc-Ala esterified to 8 grams of the supporting cross-linked polystyrene resin. The following 29 cycles of coupling were completed by using the symmetric anhydride method and DCC as the coupling reagent. The side-chain protections were as follows: Glu, Cys, Ser, Tyr, and His were protected by Bn groups; Lys by a Cbz group; Arg by a Tos group. Cleavage of the peptide from the resin was done by firstly bubbling HBr through a solution of resorcinol in TFA and then into a suspension of the peptide resin in TFA that contained Met (92). The peptide was precipitated from water to remove the Met. The yield of partially protected peptide was 64%, which was based on the amount of Ala originally esterified to the resin. The partially protected peptide was thoroughly dried and then treated with sodium in liquid ammonia as described by Niu et al. (93), except that the stable light blue end point was limited to exactly 15 seconds to prevent excessive cleavage of the Thr-Pro bond. Under these conditions, this cleavage was only 20-25%, whereas 80% was lost during a 60-second treatment. The shorter time was adequate for complete debenzylation of His and Cys and complete detosylation of Arg. The deprotected triacontapeptide was converted to the S-sulfonate. On electrophoresis, a major Pauly-positive spot existed with the same mobility as that of the B-chain S-sulfonate (BSSO3) obtained by sulfitolysis of natural bovine insulin, and a minor contaminant probably caused by B1-27. The overall yield from the first Ala residue was 21%.

Figure 11. The structure of insulin.

The A chain was synthesized by the automated solid-phase procedure (94). Three grams of Na-Boc-Asn resin was carried through 20 reaction cycles as described for the B chain except that the reagents used for all deprotection and neutralization steps were 4M HCl in dry dioxane and triethylamine in CHCl3, respectively (95). The peptide was cleaved from the resin as described above (yield, 69%). The total time required was 8 days. The S-benzyl protecting groups were removed by treatment with sodium in liquid ammonia (96), and the four cysteine residues were converted to the S-sulfonates (ASSOB) (over all yield, 37%).