Process Technology: An Introduction - Haan A.B. 2015

1 The chemical industry

1.2 General characteristics of the chemical industry segments

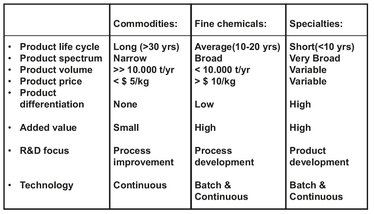

The major sectors of the chemical industry are categorized on the basis of end product uses in Fig. 1.3. Going from commodities, through fine chemicals, to specialty chemicals, the products become higher-priced, have a higher added value, a lower volume, and generally a shorter lifecycle than the products closer to the fossil fuels in the value chain. Within the chemical process industries, batch processing is focused on the fine and specialty chemicals sectors, while continuous processing is dominant in bulk chemicals production. The scale of operations ranges from quite small plants (a few tons per year) in the fine chemical area to the giants (100-1000 thousand tons per year) in the petrochemical sector. Today a typical base petrochemical plant is designed to produce enormous quantities (100-600 ktons/year) of a single product and operate 24 hours a day all year round. They are used to make key intermediates, which are turned into a very wide range of products by further processing. Clearly such large and sophisticated plants require a very high capital investment and are characterized by high investment versus low labor components in the cost of manufacture. The investment per worker in a base petrochemicals olefins plant may well exceed a quarter of a million dollars. Although these plants take full advantage of the economy of scale effect, the losses due to running under design capacity can be extremely high if the balance between production capacity and market demand is disturbed. This is particularly evident when the economy is depressed, and the chemical industry’s business tends to follow the cyclical pattern of the economy, with periods of full activity followed by those of very low activity.

Fig. 1.3: The three main segments of the chemical industry.

It is important to keep in mind that, although most of the discussion about the chemical industry tends to revolve around the multinational giants, the industry is very diverse and includes many small-sized companies as well. There is a similar diversity in the sizes of chemical plants. Batch-type plants are used for the manufacture of relatively small amounts of fine and specialty chemicals, typically up to 100 tons per annum. They are therefore not dedicated to producing just a single product, but are multipurpose and may be used to produce a number of different chemicals each year. In this part of the chemical industry the investment level may not exceed the order of $25 000 per worker.

The research and development carried out in industry can be divided into product development, process development, process improvement, and application development. The nature of the research and development being carried out varies significantly across the various sectors of the chemical industry. In the commodity chemicals sector, most of the R & D expenditure will be devoted to process improvement. Process improvement relates to processes which are already operating. It may be due to problems which have arisen which have hindered or stopped production. More commonly, however, process improvement will be directed at improving the profitability of the process. Improving the quality of the product, by process modification, may lead to new markets for the product. In recent years the most important process improvement activity has been to reduce the environmental impact of the processes. At the other end of the scale lie the specialty chemicals. Here there are immense and continuous efforts undertaken to discover and develop new products which exert the desired, specific effect. As such, the main focus in this sector is on new product development, such as pharmaceuticals, agrochemicals, and antioxidant additives. Process development absorbs considerable resources in the fine chemicals industry, in part because of the shorter life cycles of fine chemicals as compared to commodities. It covers developing new manufacturing processes for new as well as existing products. The push for the latter may originate from the availability of new technology or a change in the availability and/or cost of raw materials. Process development for a new product depends on things such as the scale on which it is to be manufactured, the by-products formed, and the required purity.