Industrial Chemistry: For Advanced Students - Mark A. Benvenuto 2015

Linear alpha olefins (LAO)

The older term for a double bond, “olefin,” is still associated with this specialized series of organic, straight chain alkenes. Also, they are sometimes called normal alpha olefins; thus the abbreviations LAO and NAO are used interchangeably.

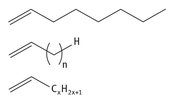

Although several different molecules fall into this category, all of the lower molecular weight LAOs have one basic use: to adjust the characteristics of the finished product when making polyethylene. Usually, an LAO is added as a co-monomer to produce low-density polyethylene (LDPE), although very small amounts of co-monomeric LAO can be used in the production of high-density polyethylene (HDPE). The higher molecular weight LAOs have a very broad application profile throughout different industries. Different ways to represent the general formula and structure for LAOs is shown in Figure 5.1, as is the representative example 1-octene.

Fig. 5.1: Formula and structure of LAOs.

5.1 Methods of production

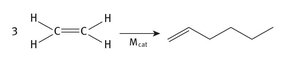

Several different companies produce LAOs, which means there are numerous small variations for the production of these materials. Broadly though, the production of LAOs is either done by the oligomerization of ethylene — the prime method — or by a Fischer—Tropsch synthesis, which must be followed by product separation and purification. The simplified reaction chemistry of ethylene oligomerization to 1-hexene (a material also sometimes called hexylene or butyl ethylene ) is shown in Figure 5.2. Broadly, the process is similar up to materials such as 1-octadecene.

Fig. 5.2: Oligomerization of ethylene.

The oligomerization of ethylene is the main reason LAOs tend to be produced in even-numbered units (1-butene, 1-hexene, 1-octene, etc.), although odd numbered carbon chains are not impossible to produce. The following name processes are used for the production of LAOs:

1. Ethyl Corporation, or Ineos Process (Ineos, 2014)

2. Gulf Chevron Phillips Process (Chevron Phillips, 2014)

3. Idemitsu Petrochemical Process (Idemitsu, 2014)

4. IFP dimerization, used to produce 1-butene

5. Phillips ethylene trimerization process, used to produce 1-hexene exclusively (IHS, 2014)

6. SABIC-Linde Alpha-Sablin Process (SABIC-Linde Alpha-Sablin Process, 2014)

7. Shell Oil Company Process, or SHOP (Shell Oil Process, 2014).

The five companies and processes mentioned that are not noted for producing a single product produce a wide molecular weight distribution of LAOs, which can be separated so that specific product components can be put to different uses.

5.2 Uses of the different LAOs

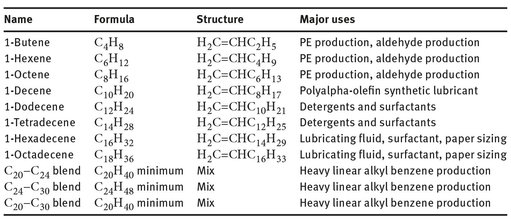

The following linear alpha olefins in Table 5.1 find uses in various industries, although there are always niches for those not listed here, or for some of those that are listed, but for which there are smaller, secondary uses.

As seen above, linear alpha olefins have a wide profile of uses, depending on the molecular weight of the LAO in question. The lighter weight materials, specifically 1-butene, 1-hexene, and 1-octene, all find use almost exclusively to produce LDPE by increasing the branching as the polymer forms. Higher molecular weight materials can be used in widely different areas, though. Chevron Phillips, a major producer, states at their website:

“Normal alpha olefins, featuring highly accessible terminal double bonds, are ideal materials for manufacturing numerous products. Normal alpha olefins or their derivatives are used extensively as polyethylene co-monomers, plasticizers, synthetic motor oils, lubricants, automotive additives, surfactants, paper size, and in a wide range of specialty applications. As major petrochemical building blocks, their use in the development of new chemical products is virtually unlimited” (Chevron Phillips, 2014). The higher molecular weight LAOs find use as the “plasticizers, synthetic motor oils, lubricants” and other materials that are used to produce end products with specific viscosities and other desired characteristics.

Table 5.1: LAO formulae and uses.

Paper sizing is one other use of the LAOs of C16—C18 chain length. This refers to creating paper surfaces that are water repellent enough that inks dry on the surface, and is not absorbed into the paper. The resistance to water that is exhibited by high-grade papers is a result of the added paper sizing. Absorbent papers, such as paper towels, are referred to as “unsized papers.”

5.3 Recycling and reuse

Since lighter LAOs are entirely used as starting materials for plastics, many of which are designed for robust performance and thus long life, any discussion of recycling is that of recycling of the plastics. Higher-molecular weight LAOs are routinely used in processes that do not recycle their end materials.

Bibliography

Chevron Phillips. Website. (Accessed 11 January 2014, as: http://www.cpchem.com/bl/nao/en-us/Pages/Products.aspx).

Idemitsu. Website. (Accessed 13 May 2014, as: http://www.idemitsu.com/products/petrochemicals/chemicals/alphaolefin.html).

IHS. Website. (Accessed 13 May 2014, as: http://www.ihs.com/products/chemical/technology/pep/reviews/hexene-from-ethylene.aspx).

Ineos. Website. (Accessed 13 May 2014, as: http://www.ineos.com/businesses/ineos-oligomers/products/). Lappin, G. R.; Sauer, J. D. (Eds.). Alpha Olefins Application Handbook. ISBN: 978-0824778958, 1989.

SABIC-Linde Alpha-Sablin Process. Website. (Accessed 13 May 2014, as: http://www.linde-engineering.com/en/process_plants/chemical_and_petrochemical_plants/linear_alpha_olefins/alpha_sablin/index.html).

Shell Oil Process, SHOP. Website. (Accessed 8 June 2014, as: http://www.shell.com).