Process Technology: An Introduction - Haan A.B. 2015

1 The chemical industry

1.4 Production structure of the chemical industry

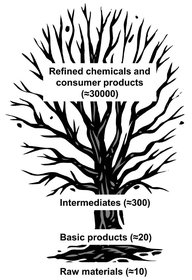

As indicated, the chemical industry is concerned with converting raw materials, such as crude oil, firstly into chemical intermediates and then into a tremendous variety of other chemical products. In an earlier period of the chemical industry’s development, chemical companies were generally production-oriented, exploiting a process to produce a chemical, and then selling it in rapidly expanding markets. As the industry has grown, there has been a strong tendency toward integration, both forward and backward. If today’s production structure of the chemical industry is examined, it is seen that there are only a few hundred major basic products and intermediates that are produced on a scale of at least a few thousand to several million tons per annum worldwide. This relatively small group of key products, which are in turn produced from only about ten raw materials, forms a stable foundation on which the many branches of refining chemistry (dyes, pharmaceuticals, etc.), with their many thousands of often only short-lived end products, are based. This has resulted in the well-known product family tree, schematically depicted in Fig. 1.4, which can also be regarded as being synonymous with an integrated production system, with synergies that are often of critical importance for success.

Fig. 1.4: Product family tree of the chemical industry.

A special characteristic of the major basic products and intermediates is their longevity. They are statistically so well protected by their large number of secondary products and their wide range of possible uses that they are hardly affected by the continuous changes in the range of products on sale. Unlike many end products, which are replaced by better ones in the course of time, they do not themselves have a so-called life cycle. However, the processes for producing them are subject to change. This is initiated by new technical possibilities and advances opened up by research, but also dictated by the current raw material situation. Here it is not the individual chemical product, but the production process or technology which has a life cycle.

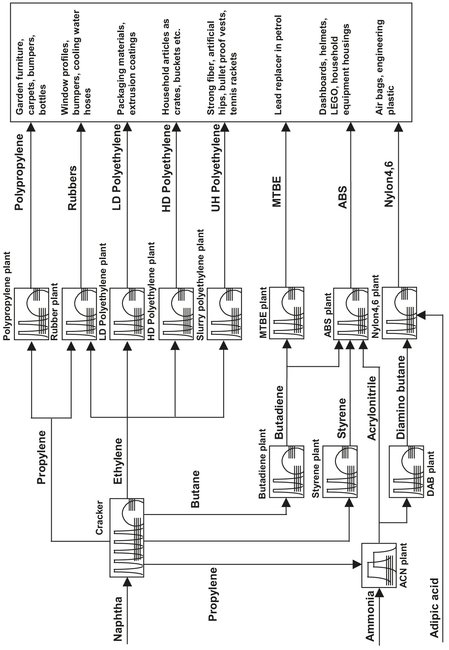

Fig. 1.5: Production chain for naphtha to polymers.

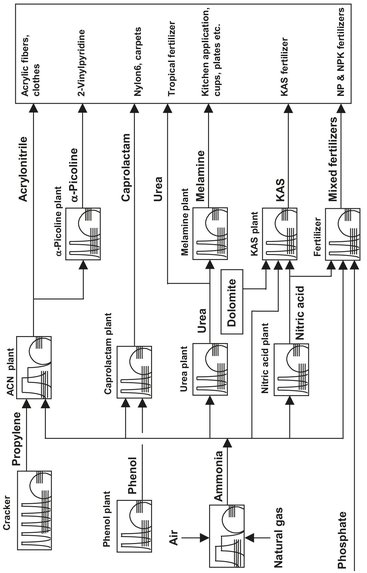

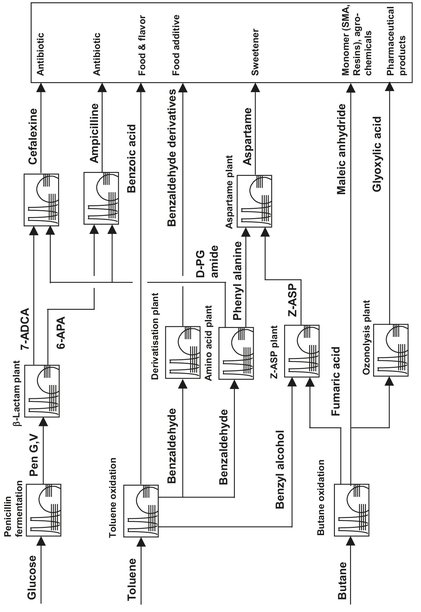

The relations between raw materials, intermediates, semimanufactured products, and finished products are complex. For the chemical industry, the cracking of naphtha and gas oil is an important operation to produce raw materials such as ethylene, propylene, and benzene. These are then used as raw materials for further processing, as shown in the product tree depicted in Fig. 1.5. The polymers sector is the major user of petrochemical intermediates and consumes almost half the total output of organic intermediates produced. It covers plastics, synthetic fibers, rubbers, elastomers, and adhesives. Ammonia and fertilizers is a sector in which it has been difficult to achieve a balance between capacity and demand. In tonnage terms it is one of the most important sectors, based on the Haber process for ammonia. As shown in Fig. 1.6 a large variety of products begin with ammonia as the basic intermediate. Based on a combination of petrochemical intermediates and natural raw materials such as glucose, the fine chemicals sector (Fig. 1.7) produces an amazingly wide range of products for an even wider range of applications. Along with pharmaceuticals, agrochemicals is a very profitable area, because the demand for its products is unaffected by the global economy and therefore remains high even during recessions. This contrasts with the situation for most other sectors of the chemical industry. The product trees presented here are especially useful in the development of new processes and products.

Fig. 1.6: Production chain from ammonia to chemical products and fertilizers.

Fig. 1.7: Production chain for glucose, toluene, and butane to fine chemicals.