Process Technology: An Introduction - Haan A.B. 2015

2 The structure of chemical and biochemical process systems

2.1 Structure of chemical and biochemical processes

The route along which a raw material is converted to products is a logical coupling of interconnected operations: the process. At least one of the process units is the chemical reactor in which chemical conversion takes place. In principle, every chemical reaction shows incomplete conversion and often the formation of by-products. Furthermore, auxiliary materials are often used which must be separated in another process step.

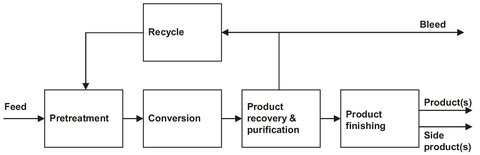

Fig. 2.1: General representation of a process.

Raw materials are generally impure, have the wrong physical form, or even consist of mixtures of different compounds. Process units preceding the reactor prepare the feed with mechanical operations such as crushing or grinding, followed by physical treatments such as mixing, heating, and evaporating. Operations succeeding the reactor treat the converted mass to recover and purify the product to the desired specification, generally utilizing a series of separation steps. Hence, in most cases a plant contains a large number of separation steps, the investment in which typically accounts for 50-70% of total plant investments. Unconverted feed components and auxiliary chemicals will generally be recycled after further purification in the recycle section. Often a part of the recycle is purged to avoid build-up of contaminants that are difficult to remove. Final product treatment usually consists of mechanical operations such as drying, granulation, and packing.

Besides the desired product, usually several waste streams are produced which must be brought into an acceptable condition before leaving the plant. Ideally only air and water are emitted. After the combination of all process steps and streams, a complicated network results.