Process Technology: An Introduction - Haan A.B. 2015

11 Particle removal from gases

11.4 Cyclones

It has been known for decades that collection by means of centrifugal forces is much more efficient than simple gravity separation. Because of their simple design, reliable operation, small space requirement, and low cost, cyclones are widely used in many industries. They are frequently employed in material recovery from gas recycling systems, pneumatic conveying, and other areas. Because cyclones can be operated at temperatures over 1000 °C, they currently provide the only method of particle collection at high temperature for use on an industrial scale. The advantages of cyclones over other collectors are offset by the fact that they are less efficient collectors for particle sizes below 1-5 µm. Therefore the use of cyclones is restricted, and they are often used as first stage collectors.

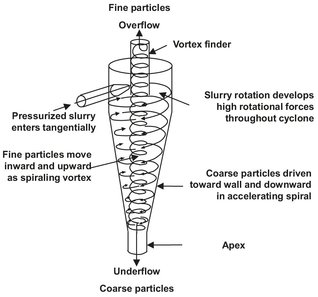

Fig. 11.7 shows the most common type of cyclone with flow reversal. The gas path is designed to impart a twist to the particle-laden gas entering the rotationally symmetrical apparatus. A turbulent three-dimensional rotational flow is produced. In the separating chamber spiral, downward flow takes place at larger radii. the flow is then reversed, and the gas spirals upward at smaller radii and reaches the exit duct. The particles in the revolving gas experience centrifugal forces hundreds to thousands of times greater than the force of gravity. Thus the larger particles migrate outward to the cyclone wall, where they collect and are carried downward and out of the separating chamber.

Fig. 11.7: Schematic diagram of a reverse-flow cyclone.

The collection performance of a cyclone depends mainly on its geometry, gas throughput, inlet gas concentration, and the properties of the material to be separated. An increase in gas viscosity decreases performance. Collection efficiency can be improved by altering the cyclone geometry or by increasing the volume-flow rate through the cyclone. In both cases the tangential velocity increases so that a greater centrifugal force acts on the particles. Most cyclone manufacturers provide grade-efficiency curves to predict overall collection efficiency of a dust stream in a particular cyclone. A problem with the development of generalized grade-efficiency curve equations is that the efficiency of a cyclone is affected by its geometric design. The following equation was proposed to calculate the smallest particle size collectable in a cyclone with 100 % efficiency:

![]()

(11.9)

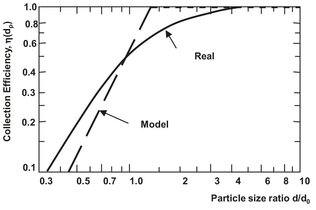

where Ne is the effective number of spirals the gas makes in the cyclone, For smaller particles the theory indicates that efficiency decreases according to the dotted line of Fig. 11.8. Experimental data show that eq. (11.9) tends to overstate the collection efficiency for moderately coarse particles and understate efficiency for the finer fraction.

Fig. 11.8: Comparison of theoretical and real collection efficiency of a cyclone.

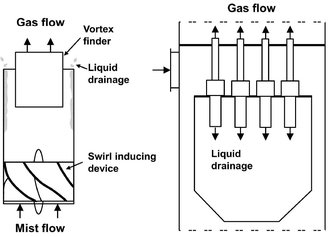

An alternative to classical cyclones is the so-called swirl tube separator shown in Fig. 11.9. It essentially consists of a swirl generator, which comprises guide vanes and a central body. The guide vanes impart a rotational motion to the passing gas so that the entrained particles are flung against the wall. These swirl tubes differ from axial cyclones in that there is no inversion of the gas flow. Occasionally they are referred to as straight-through cyclones. For the most part, swirl separators are installed in vertical gas outlets and stacks in order to prevent particle discharge. Cleaning a gas with a given flow rate usually requires more cyclones or swirl tubes in parallel. Systems composed of many small cyclones are often called multicyclones, such as the one shown in Fig. 11.9.

Fig. 11.9: Schematic diagrams of a (a) double-inlet cyclone, (b) swirl-tube separator, and (c) multicyclone package.