Process Technology: An Introduction - Haan A.B. 2015

14 Solids finishing technologies

14.1 Overview

Solids technology is concerned with the production of disperse solid products. Characteristically, the properties of solid products depend not only on chemical composition but also on the state of dispersion. The production processes are composed of individual unit operations, which include all necessary activities from preparation of the solid to packaging the product for sale.

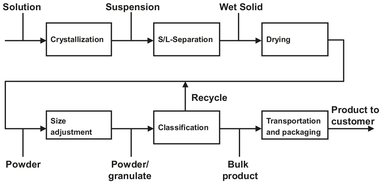

The production of disperse solid products characterized by the generation and repeated modification of dispersed states. A typical example of a solids processing chain, illustrated by Fig. 14.1, includes all required unit operations to convert a homogeneous solution into a packaged product with the desired particle morphology. Every unit operation in the processing chain modifies the physical and dispersed state of the product. The state changes from solution to a suspension that contains individual particles or loose flakes in crystallization. These particles are considerably compacted to form wet, loose agglomerates during solid/liquid separation. Drying results in particles which can be formed into larger secondary agglomerates or pulverized at the size adjustment stage.

Users of solid chemicals demand that the end products have clearly defined properties which depend on the state of dispersion of the material. These application properties, on which the performance of a dye, medicine, sweetener, or fertilizer may depend, include dispersability, dissolution rate, floating capacity, abrasion resistance, and freedom from dust. Modifying the state of dispersion throughout the solids processing chain leads to a product with the desired application properties. However, the processing chain affects the application properties not only in predetermined ways but also in many cases accidentally.

Fig. 14.1: Typical solids technology processing chain.